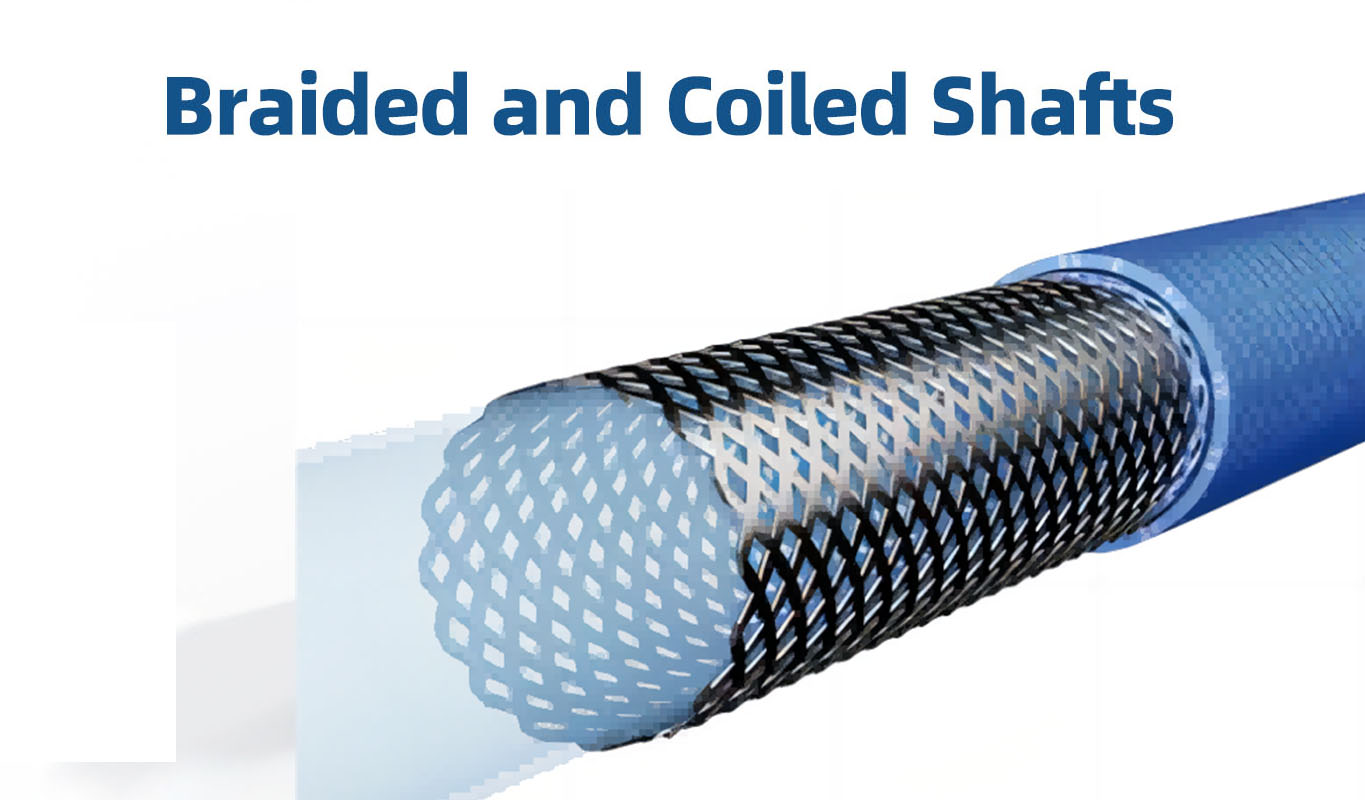

Braided Sheath Tubing

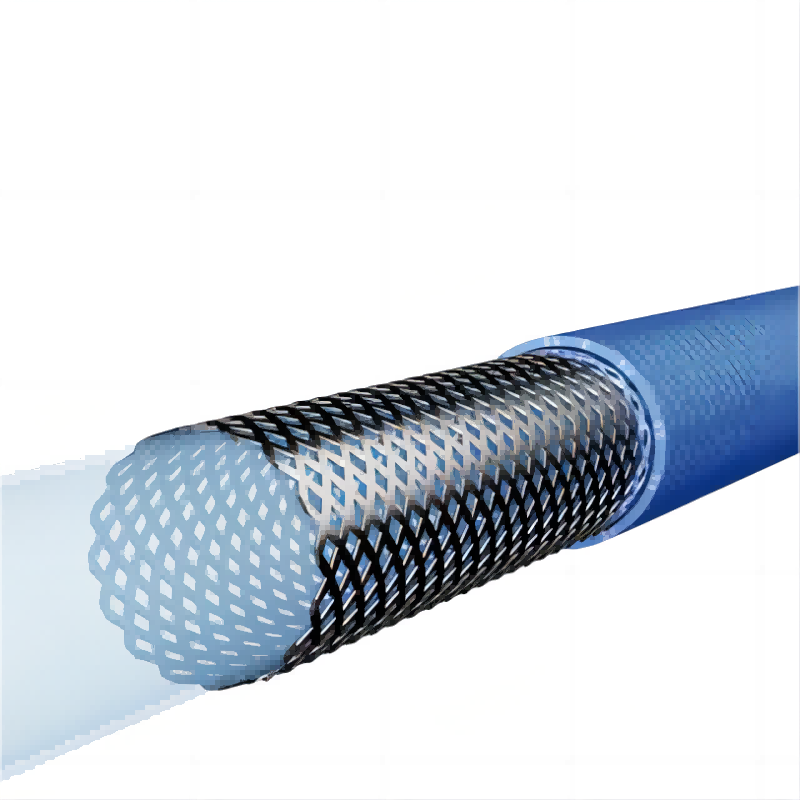

For your wires and cables, braided sheath tubing—also referred to as braided sleeving—serves as a hero. This barrier, which is generally made of durable materials like PET or nylon, protects against common dangers. Your electrical components are protected from wear and tear by its exceptional abrasion and corrosion resistance, which is provided by its braided design.

Braided Sheath Tubing types

Braided Sheath Tubing: The All-Star Lineup of Key Features

Unmatched Strength & Durability:

Flexibility for Simple Installation:

Customization is king:

Applications Beyond Wires:

- We are looking forward to being your OEM/ODM strategic partner in China!

- We have more than 10 years of OEM/ODM experience.

- We have established strategic OEM (Original Equipment Manufacturer) partnerships with a lot of European and American companies.

Braided Sheath Tubing: More Than Just Cable Armor:

Controlling the Flow:

Braided sheath tubing is essential in the field of pneumatic and hydraulic systems. It protects air transfer lines and high-pressure fluid lines from outside harm. Because of its resistance to abrasion and crushing, these systems operate smoothly and don’t leak or fail.

Strengthening Industrial Workhorses:

Industrial tubes and hoses are frequently exposed to hostile conditions. It fills up here as a dependable barrier. These essential parts are shielded from external abrasion by their sturdy design, which increases their longevity and reduces downtime for upkeep and repairs.

The Invisible Guardian:

As it was intended to do, braided sheath tubing continues to protect electrical cables and wires. Its resistance to abrasion, heat, and chemicals assures excellent electrical performance and prolongs the life of these vital components, which are essential for complicated wiring harnesses and elaborate control panels alike.

Getting Ready for Performance:

Reliable protection for crucial components is necessary in the challenging fields of automotive and aeronautical engineering. Sheath tubing with braids steps up to the plate. Because of its lightweight yet sturdy design, cables, hoses, and other parts are protected from the damaging effects of vibration, high temperatures, and inclement weather, allowing cars and aeroplanes to operate at their best.

Braided Sheath Tubing: Powerhouse Protection with Unmatched Advantages

An exceptional strength-to-weight ratio when strength and efficiency meet

It provides extraordinary strength without adding weight, in contrast to large metal casings. This is because of its distinctive braided design, which frequently makes use of robust yet lightweight materials like PET or nylon. This means that installation will be simpler, structures will be less stressed, and overall efficiency will increase.

Insensitive to Heat, Pressure, and Chemicals:

It is impervious to harsh situations. Its material characteristics frequently offer improved chemical, heat, and pressure resistance. This ensures dependable performance even in difficult environments by protecting your underlying components

from harm, leaks, and malfunctions.

The key to flexibility is ease of installation and manoeuvrability:

Don’t be duped by the strength! Because of its remarkable flexibility, braided sheath tubing is simple to install in complex configurations and around tight corners. This streamlines your assembly process by making things easier and reducing the need for extra connection points.

An Unwavering Shield: Enhanced Defence for Essential Components

It serves as a guardian angel for your essential parts. It provides excellent resistance to abrasion and external wear and tear. It may also offer insulation against chemicals and heat, guaranteeing that the systems it guards operate as best they can.

Made to Last: Extended Life & Sturdiness

Because of its strong structure, your covered

components will last longer due to resistance to deterioration. This results in lower maintenance expenses and increased system dependability overall.

Sheath Tubing Braided: Material Wonders for Protection

Sturdiness and Rusting:

Stainless steel excels in situations requiring the highest strength and remarkable corrosion resistance. This material option grows well in abrasive situations, such as coastal settings or high-humidity regions. Stainless steel provides unparalleled protection and durability but is somewhat heavier than other materials.

Polyester

Looking for a dependable and reasonably priced solution? Polyester (PET) is a widely used material. It is flexible and has high abrasion resistance, making it appropriate for a range of uses. In some combinations, PET can also be flame retardant, which adds another degree of security.

Nylon

It is a flexible material that combines strength, flexibility, and affordability in a well-rounded way. It is appropriate for a variety of applications because of its strong chemical compatibility and abrasion resistance. In daily situations, nylon is a common material choice for wire and cable protection.

Polyurethane

If you are looking for the highest level of flexibility, polyurethane (PU) is the answer. Applications needing a lot of bending or movement suit this material well. PU provides an additional layer of protection by having superior chemical compatibility and abrasion resistance.

PTFE (Teflon)

When it comes to severe temperatures, Teflon, or PTFE, is the best option. Because of its remarkable heat resistance, this material is perfect for situations where high temperatures are present. Moreover, PTFE has low friction characteristics and excellent chemical resistance.

Braided Sheath Tubing: A Symphony of Customization for Tailored Protection

Inner tube material and diameter

The inner layer is where the tubing’s heart begins. Depending on what your application requires, you can select from a variety of materials including nylon, PU, or even PTFE. Furthermore, the inner diameter may be precisely adjusted to ensure that your components, hoses, or cables fit tightly, providing the best possible protection and a tidy appearance.

Outer braid material, weave, and pattern

The outside braid provides a platform for customisation; it is the “armour” of the tube. Depending on the needs of the application, materials might be anything from strong stainless steel to nylon at a lower cost. It is also possible to adjust the weave patterns, with looser braids providing greater flexibility and tighter ones providing greater resistance to abrasion.

Length and end fittings

Because braided sheath tubing may be made to order in any length, it will fit your application precisely. There are many solutions available, whether you require lengthy lines for intricate wire systems or short sleeves for specific components. To provide a smooth connection to your cables, hoses, or structures, several end fittings can also be included.

Color and appearance

Although safety is of the utmost importance, braided sheath tubing doesn’t have to be boring. Numerous manufacturers provide an extensive selection of colours, so you may add your unique style or follow predetermined colour patterns.

Conclusion:

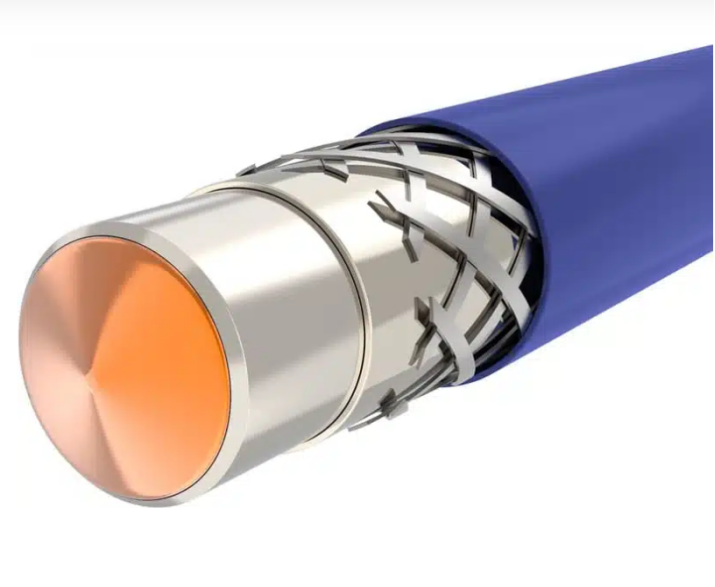

At Demax, our primary areas of expertise are disposable interventional therapy product development and manufacturing. Demax has so far forged enduring partnerships with clients and healthcare facilities in more than 90 nations, and our goods are distributed all over the world.

Dedicated Demax Team

- Responsive to customer needs

- Total customer satisfaction

- Seamless project transfers from customers

- Total project setup time reduction

- Action performby Engineer and quality team