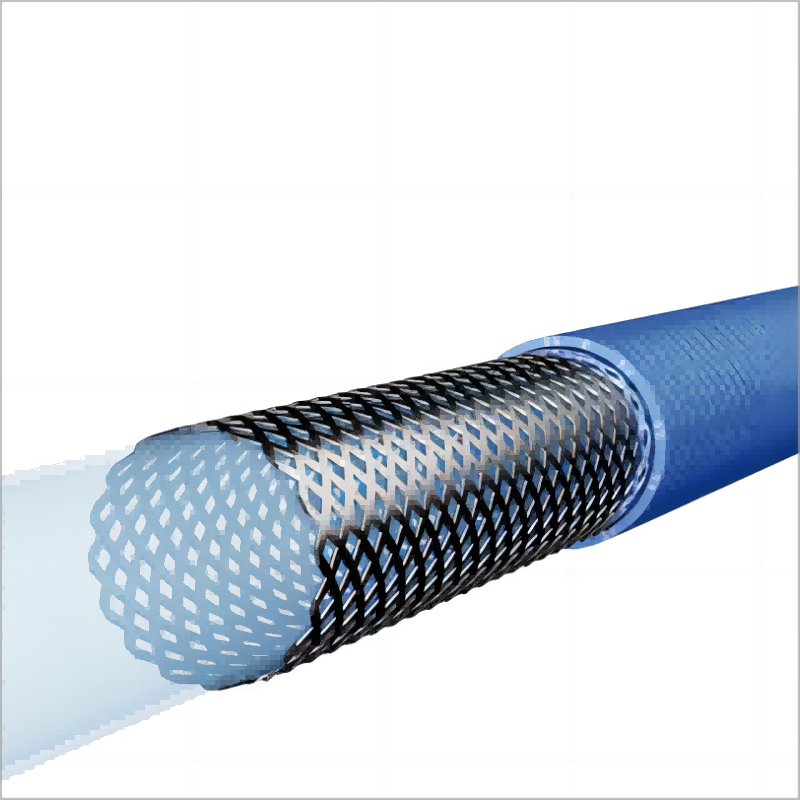

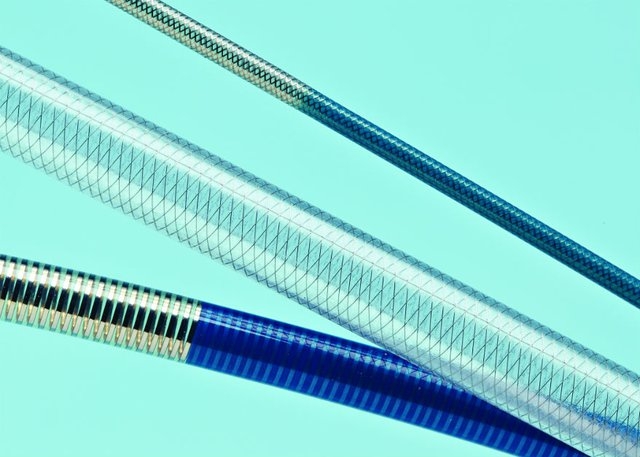

Braid Reinforced Shafts, produced by Demax, play a crucial role in medical interventions by combining strength and flexibility. These shafts are intricately designed to withstand high-pressure fluid delivery and provide robust structural support, making them indispensable in specialized procedures including vascular interventions, endoscopy, and urology. With dimensions ranging from an inner diameter of 0.5-15 mm and a tube wall thickness of 0.07-3 mm, the precision in manufacturing these shafts is vital. The strength of these shafts ensures the safety and effectiveness of medical procedures, where precision and reliability are paramount.

Mechanics of Braided Shaft Strength

Explanation of Braiding Technique

Braiding technology in shaft production involves interlacing three or more strands of material to form a cohesive structure. This technique not only enhances the shaft’s flexibility but also evenly distributes tension across the entire length, increasing durability and resistance to external pressures.

Structural Integrity and Load Distribution

The braided design of these shafts allows for exceptional load distribution. The interwoven pattern spreads the forces exerted on the shaft during medical procedures, preventing localized stress points. This structural integrity is critical in medical settings, ensuring the shaft performs reliably under varying conditions without failing.

Comparison with Traditional Shaft Designs

Compared to traditional unbraided shafts, braid reinforced shafts offer superior flexibility and strength. Traditional designs often rely on thicker materials to achieve similar strength, which can compromise flexibility and maneuverability. In contrast, braided shafts maintain a balance between strength and flexibility, enhancing their suitability for complex medical applications.

Material Selection and Properties

Types of Materials Used in Braided Shafts

Medical-grade materials are utilized to ensure biocompatibility and safety. These materials are designed to withstand the rigors of medical procedures without causing adverse reactions, making them ideal for long-term contact with human tissue.

Strength-to-Weight Ratio Considerations

The strength-to-weight ratio is a critical factor in the design of braided shafts. Braided reinforcements significantly increase strength while minimizing additional weight. Prevents kink and collapse under pressure. Additionally, some shafts are reinforced with coils. To further improve strength and flexibility, providing additional support and stability.

Impact Resistance and Flexibility

The impact resistance of braided shafts ensures they can withstand the physical demands of medical procedures without deforming. Their flexibility is facilitated by a smooth inner surface that allows for optimal fluid flow and reduces the risk of obstruction or blockage. Moreover, these shafts are available in various sizes and lengths, accommodating different procedural needs and anatomical variations in patients.

Applications of Braid Reinforced Shafts

The Demax Braid & Coil Reinforcement Tube is integral to various medical procedures, demonstrating its versatility and importance in healthcare. Here are some of its primary applications:

Vascular Interventions

These shafts are crucial for delivering contrast media, saline solutions, or therapeutic agents during procedures like angiography, angioplasty, and stent placement. Their strength and flexibility ensure safe navigation through vascular pathways.

Endoscopy

In endoscopic procedures such as gastroscopy, colonoscopy, and bronchoscopy, these shafts are used for delivering irrigation fluids, suction, and therapeutic agents. The braided design provides the necessary durability and flexibility required for these intricate procedures.

Urology Procedures

For urological interventions like cystoscopy, ureteroscopy, and nephrostomy, the shafts deliver essential substances such as contrast media and saline solutions. Their design ensures minimal discomfort and high efficacy in fluid delivery.

Surgical Procedures

In surgeries including laparoscopy, arthroscopy, and neurosurgery, these shafts play a vital role in delivering irrigation fluids, suction, and therapeutic substances, aiding in clearer surgical fields and better outcomes.

Diagnostic Imaging

These shafts are also used in diagnostic imaging techniques like CT, MRI, and ultrasound for the administration of contrast media, enhancing the clarity and detail of images produced.

Manufacturing Processes

Overview of Braiding Methods

The manufacturing of braided shafts involves intricate braiding techniques where multiple strands of material are interwoven. This method provides unique structural benefits such as increased tensile strength and flexibility, which are critical for medical applications.

Automation and Precision Techniques

Modern manufacturing of these shafts employs advanced automation and precision engineering technologies. These technologies ensure high accuracy in dimensions and material consistency, critical for the shafts’ performance in sensitive medical procedures.

Quality Control Measures

Stringent quality control measures are implemented throughout the manufacturing process. These include regular testing for durability, flexibility, and biocompatibility, ensuring that every shaft meets the high standards required for medical use.

Environmental and Sustainability Considerations

Impact of Materials and Manufacturing Processes

The materials used in braided shafts, while chosen for their strength and safety, also consider environmental impact. The manufacturing processes are designed to minimize waste and reduce the environmental footprint.

Recycling and Waste Management Practices

Recycling and efficient waste management practices are integral to the production of braided shafts. These practices help in reducing the overall environmental impact of medical device manufacturing.

Innovations in Eco-Friendly Alternatives

Research and development efforts are continually underway to explore eco-friendly materials and manufacturing techniques that reduce environmental impact without compromising product quality. These innovations include the use of recycled materials and more sustainable production practices.

Closing Words

Demax Braid-reinforced shafts stand at the forefront of medical innovation, providing unmatched strength and flexibility crucial for a broad spectrum of medical procedures. Their unique braiding technique enhances their structural integrity, allowing for even load distribution and increased durability under the strenuous conditions of medical applications. This makes them indispensable in fields ranging from vascular interventions to diagnostic imaging, where precision and reliability are paramount. Additionally, meticulous attention to material selection and manufacturing processes ensures that these shafts are not only effective, but also safe and biocompatible for patient use. Continued advancements in environmental sustainability practices further underscore the commitment to reducing ecological footprint while maintaining high quality and performance standards. In essence, braided reinforced shafts embody a synthesis of advanced engineering, patient safety, and environmental responsibility, making them a cornerstone of future medical technology developments.