Strong PA Tubes Power Implantable Drug Delivery Systems

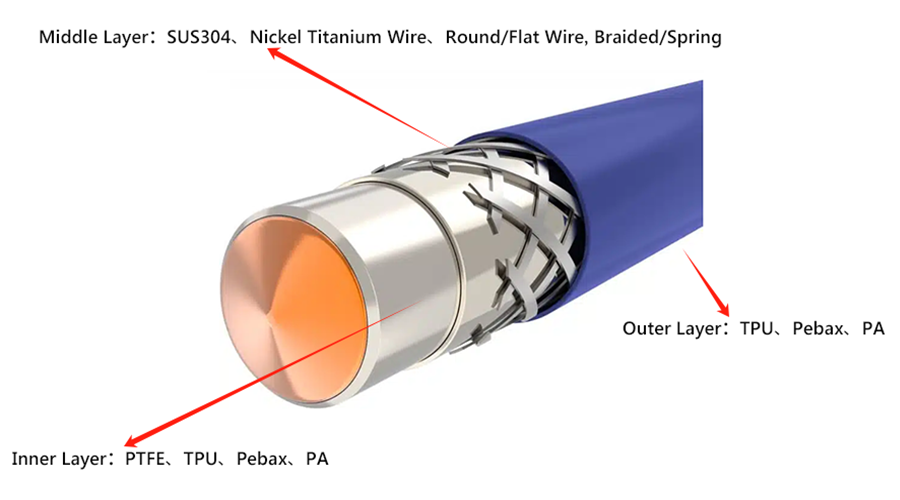

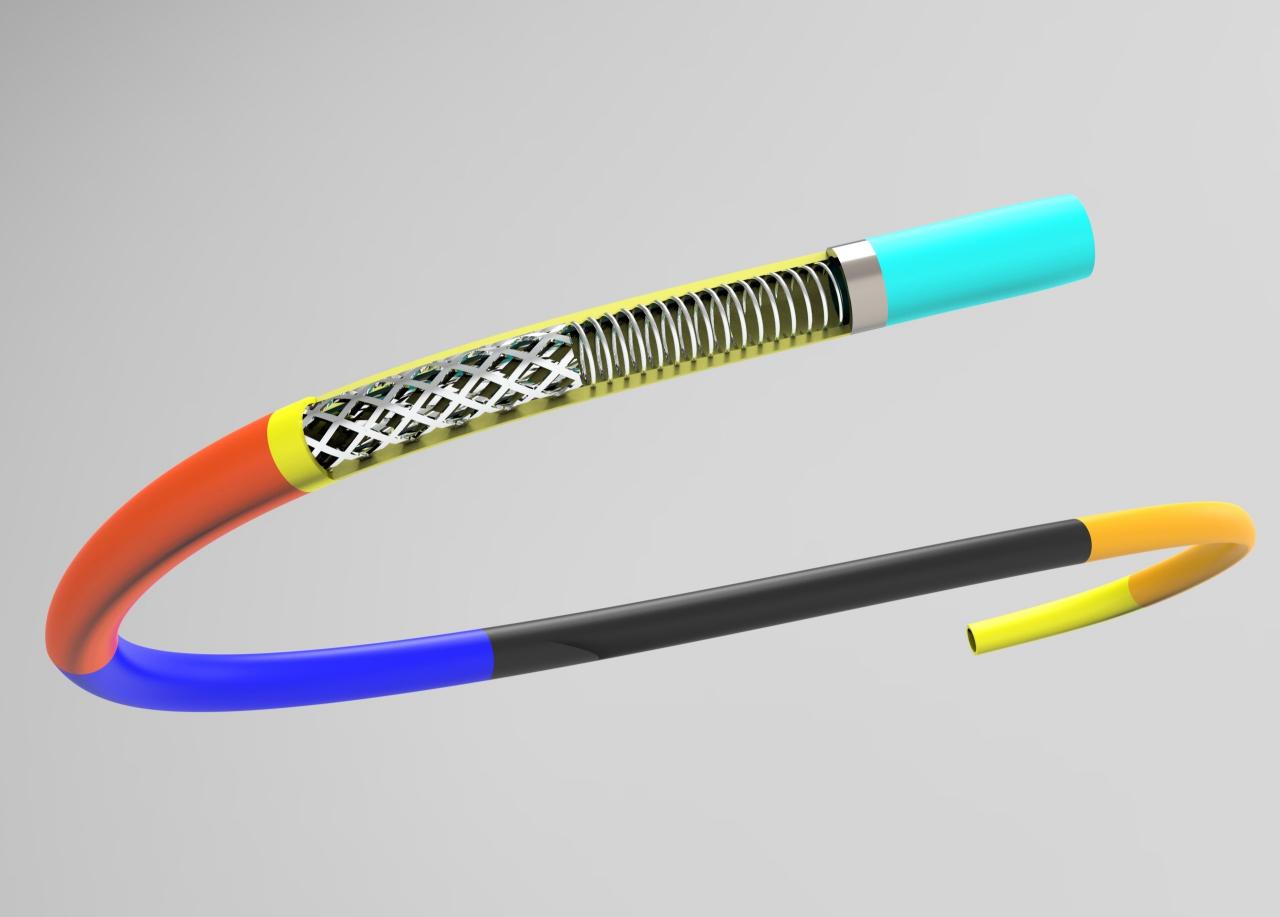

The global demand for Implantable Drug Delivery solutions is rising fast, and at Demax we believe every success story begins with a single, robust conduit – the polyamide (PA) tube. As both a manufacturer and an innovation partner, we have spent decades refining this unassuming component. Today, our durable PA tubes stand at the center of life-saving devices, ensuring therapies reach the body with accuracy, gentleness, and absolute reliability. Why Durable PA Tubes Define Implantable Drug Delivery Success A modern implant can only perform as well as the channel that feeds it. PA tubes – often called Single-Lumen Tubes – bridge the gap between formulation and physiology. They guide drugs, contrast agents, or surgical tools through delicate anatomy without compromising patient safety. Demax engineers source medical-grade polyamide for three critical reasons: biocompatibility, mechanical strength, and chemical resistance. Polyamide resists abrasion and kinking, yet remains flexible enough to follow complex vascular paths. In our clean-room lines the resin is extruded, annealed, and laser-inspected in one continuous loop, giving every meter of tubing a profile that exceeds ISO 10993 and USP Class VI. • Key Performance Benefits ✅Minimal wall variation safeguards flow precision ✅High burst pressure protects against accidental rupture ✅Smooth inner lumen reduces drag on drug payloads ✅Low-friction surface enables easy catheter tracking Bullet points tell only half the story. In practice, clinicians notice how quickly a Demax PA tube primes, how smoothly a guidewire rides its lumen, and – most important – how confidently they can advance an implantable pump without worrying about split lines or micro-leaks. These hands-on advantages translate directly into shorter procedure times and lower complication rates, both major contributors to the real-world success of Implantable Drug Delivery therapies. Demax Engineering At Demax, we believe excellence in implantable medical devices begins with precision – and that starts at the tubing level. Our PA tube production is not simply a manufacturing process, but a complete engineering ecosystem. It combines design, simulation, prototyping, testing, and ongoing clinical feedback into a seamless loop of continuous improvement. Each batch of tubing begins as a digital model. We use advanced finite-element analysis to simulate how our tubes will perform under real-world stresses – pulsatile pressure from implanted pumps, extreme flexing during catheterization, and prolonged exposure to bodily fluids. These simulations help us refine every aspect of the tube’s geometry before a single gram of resin is extruded. Once the physical production begins, every tube undergoes rigorous quality control. Automated dimensional scanners measure outer diameter and wall thickness with micron-level precision. Our tolerance window is tight: •Outer diameter range: 0.5 – 10.0 mm •Outer diameter tolerance: ±0.02 mm •Minimum wall thickness: 0.03 mm •Wall thickness tolerance: ±0.02 mm These specifications may appear ordinary, but in practice, they define the performance envelope for highly demanding applications. Our PA tubes are essential components in a wide range of devices, including microcatheters for neurovascular interventions, PTA balloon catheters for peripheral artery treatments, angiography catheters, and braided catheter shafts. In many cases, the PA material is used in both the inner and outer layers, combining