Product

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Home

- /

- Injection Molds

-

Design

The Demax mold design team has lots of experience making molds for medical devices. We use software like NX, Autocad, and Moldflow to help customers with their special needs. We optimize product designs for injection-molded parts, design molds, and improve the injection molding process. This helps reduce the number of adjustments needed for the molds and products, making the whole process faster. It also helps us check the molds and injection molding process quickly, so we can fix any problems sooner. This speeds up the whole mold development process and increases the number of good parts we can make.

-

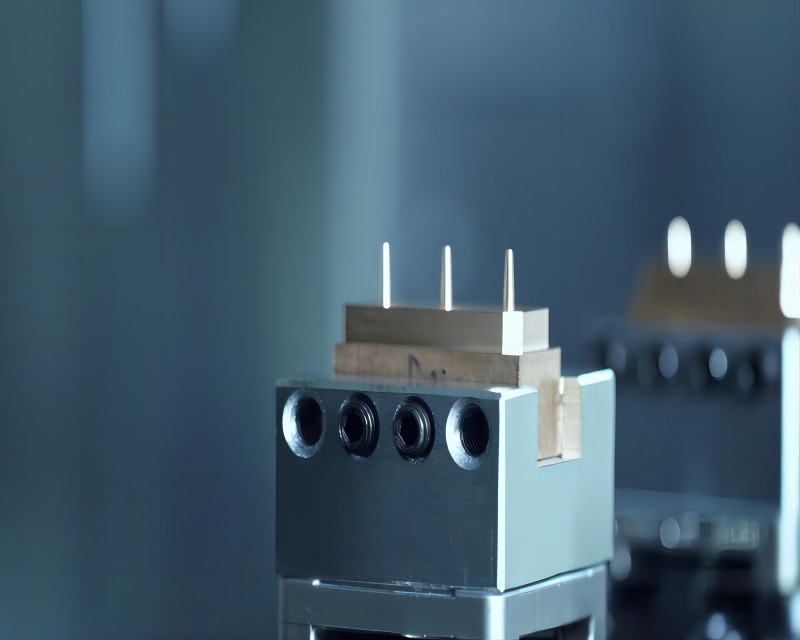

Manufacturing

Demax boasts a comprehensive array of equipment for precision injection mold manufacturing, featuring Japanese CNC machines, Japanese/Swiss precision EDM machines, Japanese wire cutting machines, Japanese NC lathes, and precision surface grinders. Our workshops are meticulously maintained with constant temperature and humidity control, fostering an optimal environment for mold production. With an advanced mold processing concept, coupled with German Zeiss three-coordinate inspection technology, we ensure unparalleled accuracy in mold fabrication. Additionally, our team comprises experienced technicians with over 10 years of expertise in processing medical injection mold parts, guaranteeing precision and reliability throughout the manufacturing process.