Product

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Home

- /

- Precision Medical Tubing

-

Angiography catheter

Features:

1. The tip is soft to reduce the risk of vascular injury;

2. PEBAX material, stronger configuration shape memory;

3. The port adopts a butterfly-wing ergonomic design, which is convenient to operate and more practical;

4. Good pushability and retractability, easy to control. -

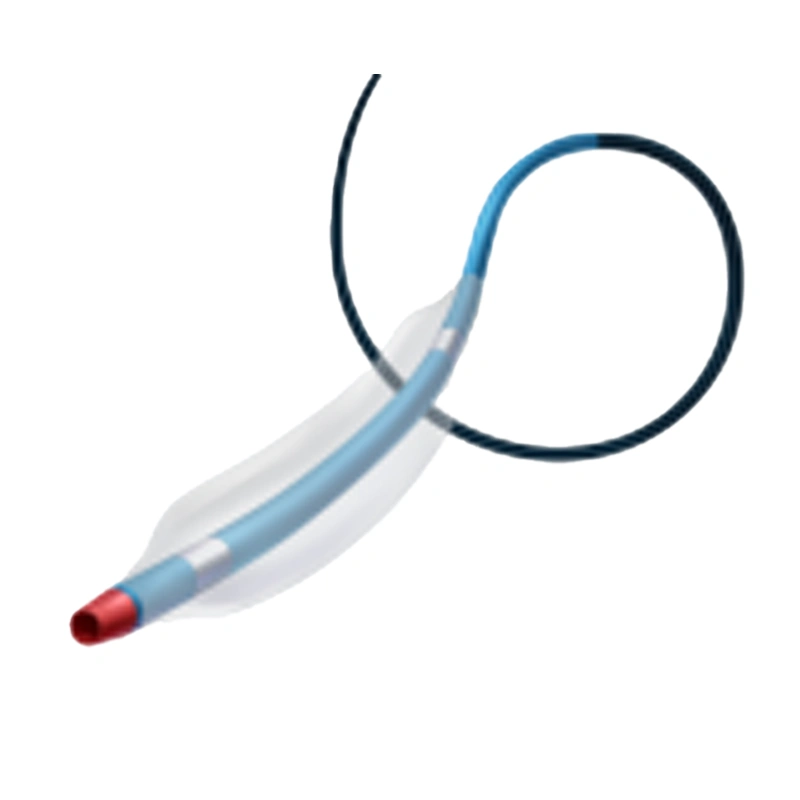

Balloon Forming

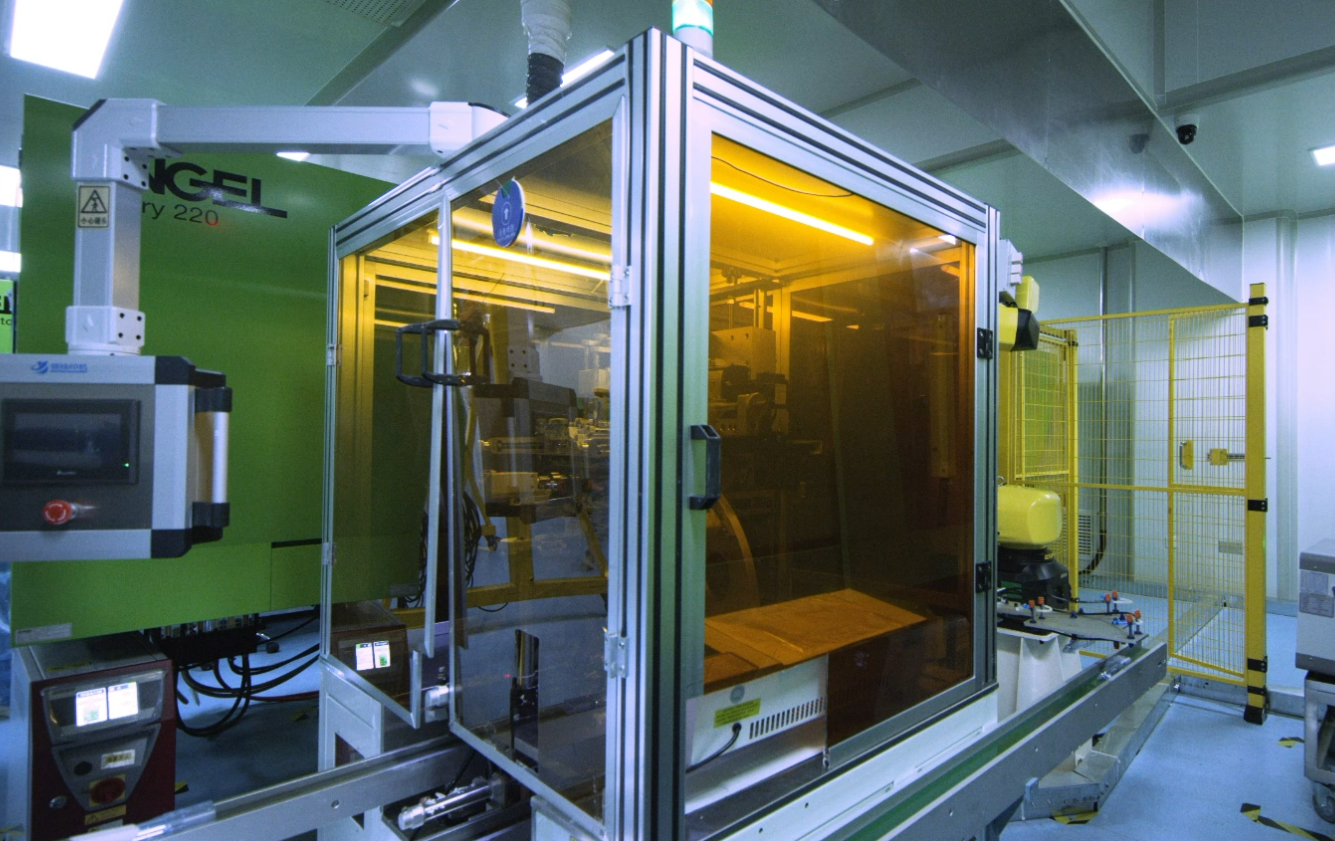

Balloon forming is an intricate process that demands technical expertise and specialized knowledge. At Demax, we use advanced techniques and cutting-edge technologies to ensure the precision and quality of this process.

This process is vital in shaping balloon catheters to achieve specific features and functionality, such as effective expansion and contraction, and providing uniform pressure. These aspects are crucial for proper applications on the arterial wall and the improvement of blood flow. Some of the advantages of our Balloon Formation Services include:

- Extensive experience and specialized knowledge in materials and medical device design

- Our team consists of highly trained experts who excel in troubleshooting and offering practical solutions for device manufacturing.

-

Balloon Tubing

- Vast Selection in the Industry

- Our range of medical balloons fits the needs of any application! What you will get is:

- Simple to complicated shapes as well as ends

- Compliant, Non-compliant, and semi-compliant type

- Diversified materials

-

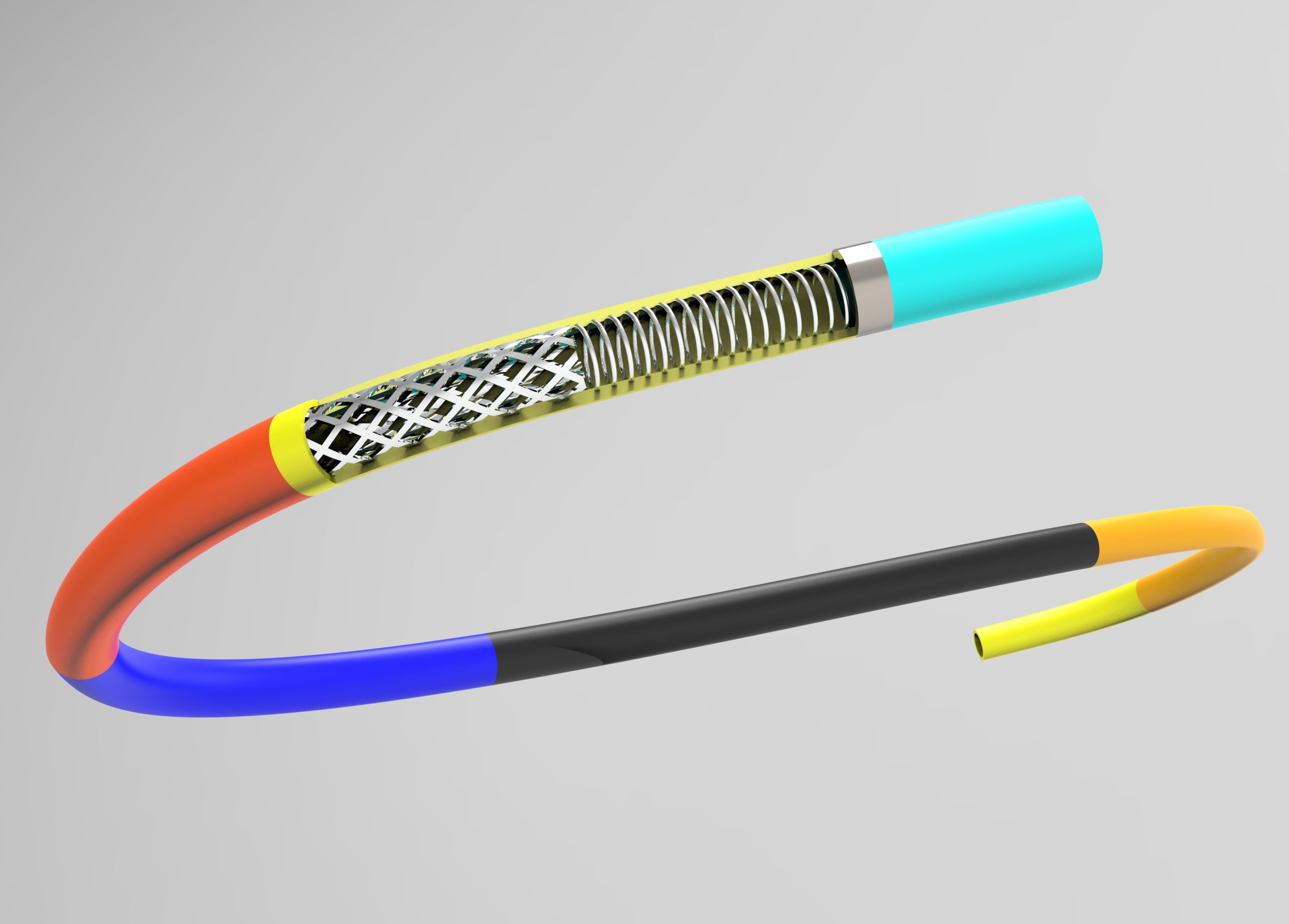

Braid & Coil Reinforcement Tube

The Demax Braid & Coil Reinforcement Tube is an innovative medical device designed to provide enhanced strength and flexibility for a wide range of medical applications. Crafted with precision and utilizing advanced materials, this reinforced tubing offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

-

Coating

Precision Medical Tubing Services Coating from Demax involves the application of specialized coatings onto medical-grade tubing substrates to enhance their performance and functionality. These coatings may include hydrophilic coatings, hydrophobic coatings, antimicrobial coatings, drug-eluting coatings, and more, depending on the specific requirements of the medical device and application. The coating materials are carefully selected for their biocompatibility, adhesion properties, and compatibility with the substrate material to ensure optimal performance and safety. Each coating is applied using precise coating techniques to achieve uniform coverage and consistent thickness, resulting in medical tubing with enhanced lubricity, biocompatibility, and other desirable properties.

-

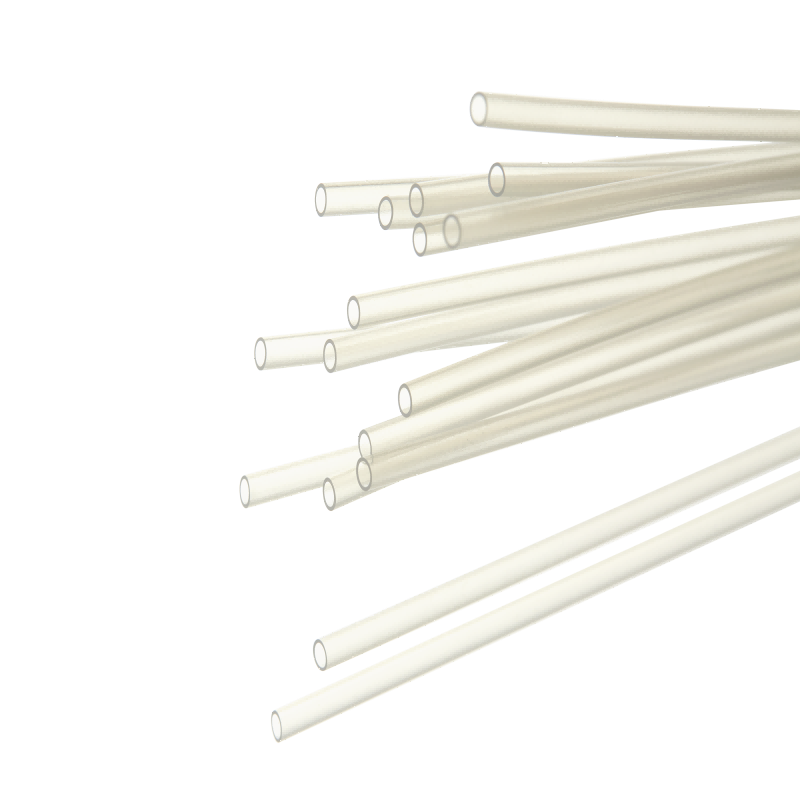

ETFE Tube

ETFE tubes manufactured by Demax are crafted from high-quality ethylene tetrafluoroethylene (ETFE) polymer.

This fluoropolymer material offers exceptional chemical resistance, mechanical strength, and biocompatibility, making it ideal for medical device applications.

ETFE tubes undergo precise extrusion processes to achieve consistent dimensions, smooth surfaces, and reliable performance in medical settings.

-

FEP Heat Shrink Tube

The FEP Heat Shrink Tube boasts a composition rooted in fluorinated ethylene propylene (FEP), a thermoplastic polymer renowned for its exceptional properties in medical applications.

FEP exhibits a unique combination of characteristics that make it ideally suited for medical tubing. Its molecular structure imparts remarkable clarity to the tubing, allowing for optimal visualization of fluids and instruments during medical procedures, essential for accurate monitoring and precise manipulation.

-

Flaring

Precision Medical Tubing Services Flaring involves the precise modification of medical-grade tubing materials to create flares and expansions. The composition of the tubing used in this process varies depending on the specific requirements of the medical device and the application. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

-

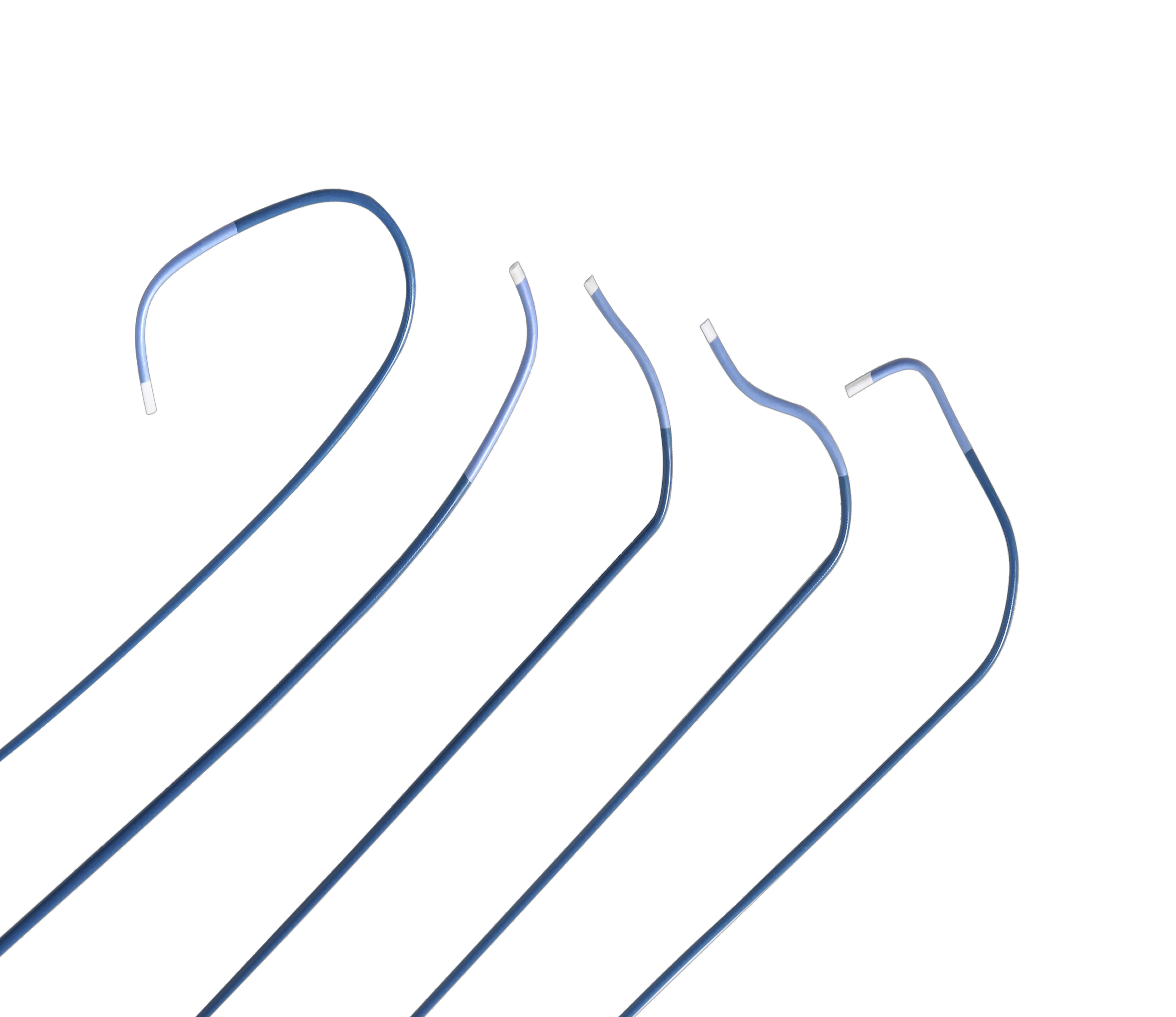

Guiding Catheter

Guiding catheters are typically composed of biocompatible materials such as polyurethane or nylon, chosen for their flexibility, durability, and compatibility with bodily tissues. The catheter shaft is reinforced with braided or coiled wires to provide structural support and torqueability while maintaining flexibility for navigation through tortuous vascular anatomy. Soft, atraumatic tips minimize trauma to blood vessels during insertion and positioning. Radiopaque markers or bands incorporated into the catheter shaft enhance visibility under fluoroscopy or other imaging modalities, allowing for precise navigation and positioning during procedures. Demax’s guiding catheters are engineered with advanced materials and design features to optimize performance and safety, ensuring successful outcomes in a wide range of interventional procedures.

-

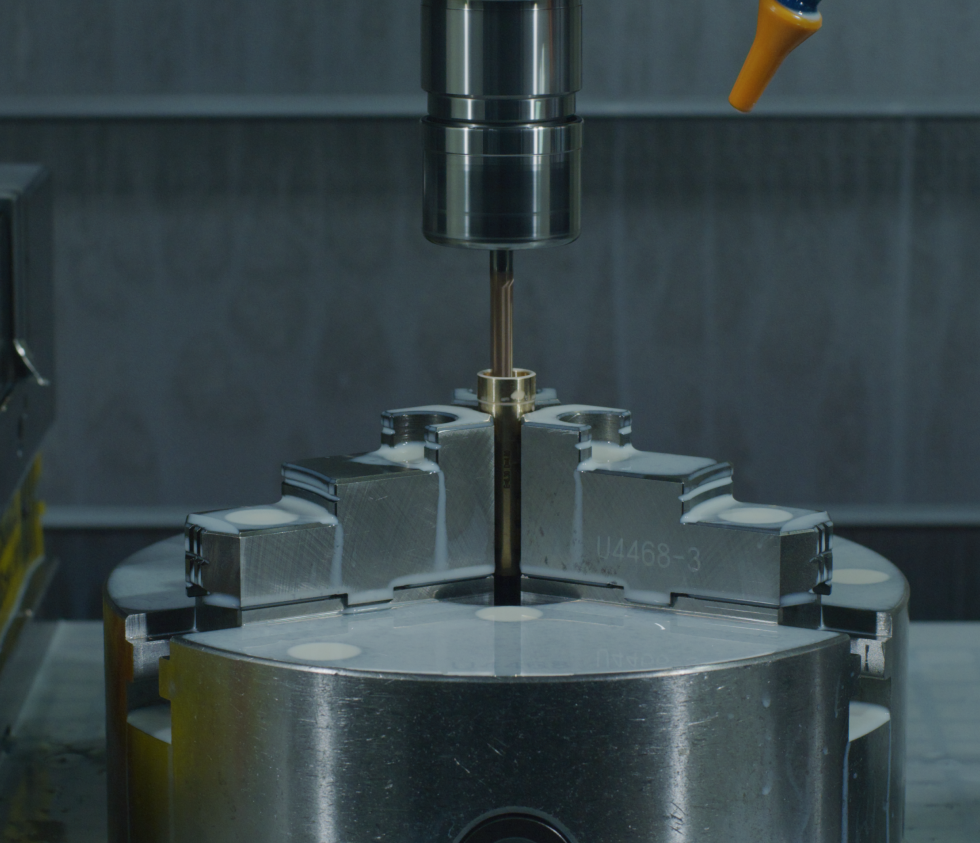

Hook Forming

Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, chosen for their exceptional mechanical properties, corrosion resistance, and biocompatibility. These materials undergo precise shaping processes to achieve intricate hook configurations tailored to specific medical device applications. With our commitment to quality and precision, Demax ensures that hook-formed components meet the rigorous demands of medical device manufacturing, contributing to the advancement of healthcare worldwide.

-

Microcatheter

Features:

1. PTFE inner layer allows for smooth passage for embolic agents;

2. Optimal trackability through tortuous anatomy;

3. Available in pre-shaped tip shape configurations for vessel engagement;

4. Four shapes provides more option for clinical usage;

5. 2.0F/2.2F/2.6F/2.8F models are available;

6. Hydrophilic coating technology, smoothly through the lesion. -

PA Tube

The PA Tube, also referred to as a Single Lumen Tube, is a crucial component utilized in various medical settings for precise fluid delivery or instrument insertion during procedures. It serves as a conduit, ensuring the seamless transfer of fluids or the introduction of medical instruments with accuracy and reliability. Constructed from durable materials, the PA Tube is designed to withstand the rigors of medical procedures while prioritizing patient safety and comfort.