Coating

Precision Medical Tubing Services Coating from Demax involves the application of specialized coatings onto medical-grade tubing substrates to enhance their performance and functionality. These coatings may include hydrophilic coatings, hydrophobic coatings, antimicrobial coatings, drug-eluting coatings, and more, depending on the specific requirements of the medical device and application. The coating materials are carefully selected for their biocompatibility, adhesion properties, and compatibility with the substrate material to ensure optimal performance and safety. Each coating is applied using precise coating techniques to achieve uniform coverage and consistent thickness, resulting in medical tubing with enhanced lubricity, biocompatibility, and other desirable properties.

- Coating Options: Demax offers a wide range of coating options for precision medical tubing, including hydrophilic coatings, hydrophobic coatings, antimicrobial coatings, drug-eluting coatings, and more. These coatings are applied using advanced coating techniques to ensure uniform coverage and consistent performance.

- Coating Thickness: The thickness of the coating can be customized according to specific requirements and application needs. Demax ensures precise control over coating thickness to achieve the desired level of functionality and performance.

- Material Compatibility: Our precision coating services are compatible with a variety of medical-grade materials commonly used in medical tubing manufacturing, including polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, and more. We carefully select coatings that are compatible with the substrate material to ensure optimal adhesion and performance.

- Biocompatibility: All coatings used in Demax precision medical tubing services are biocompatible and meet relevant regulatory standards and guidelines, ensuring the safety and compatibility of the coated tubing with the human body.

- Catheters: Coated medical tubing is commonly used in catheter assemblies for improved lubricity, trackability, and biocompatibility, enhancing patient comfort and procedural success.

- Stent Delivery Systems: Coatings applied to medical tubing used in stent delivery systems can facilitate smooth delivery and deployment of stents within blood vessels, reducing friction and potential damage to the vessel walls.

- Guidewires: Coated medical tubing is utilized in guidewire assemblies to enhance flexibility, maneuverability, and steerability during vascular interventions and procedures.

- Endoscopic Devices: Precision coating services are employed in medical tubing used in endoscopic devices for improved visualization, lubrication, and ease of navigation within the body’s natural cavities.

- Implantable Devices: Coatings applied to medical tubing used in implantable devices can improve biocompatibility, reduce friction, and prevent tissue adhesion, enhancing the long-term performance and functionality of the implants.

Related products

-

PU Braided Tube

The Demax PU Braided Tube is constructed using polyurethane (PU), a high-performance polymer known for its excellent mechanical properties and chemical resistance. This tubing is reinforced with a braided layer, providing enhanced strength and resistance to kinking and collapse. It is manufactured to meet the stringent standards of the medical industry, ensuring biocompatibility and safety for patient use. The tubing is free from latex, phthalates, and other harmful substances, minimizing the risk of adverse reactions or complications.

-

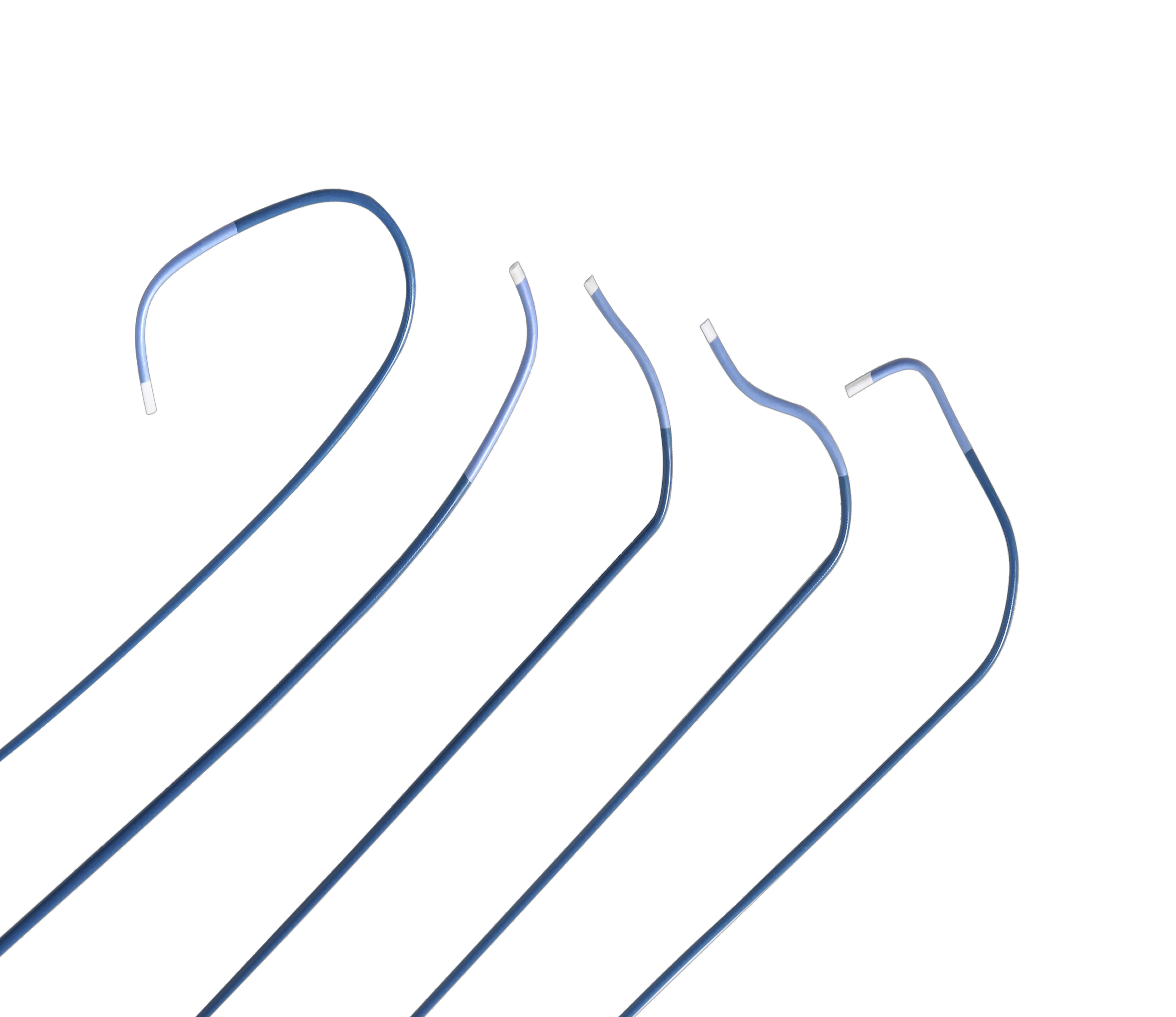

Angiography catheter

Features:

1. The tip is soft to reduce the risk of vascular injury;

2. PEBAX material, stronger configuration shape memory;

3. The port adopts a butterfly-wing ergonomic design, which is convenient to operate and more practical;

4. Good pushability and retractability, easy to control. -

FEP Heat Shrink Tube

The FEP Heat Shrink Tube boasts a composition rooted in fluorinated ethylene propylene (FEP), a thermoplastic polymer renowned for its exceptional properties in medical applications.

FEP exhibits a unique combination of characteristics that make it ideally suited for medical tubing. Its molecular structure imparts remarkable clarity to the tubing, allowing for optimal visualization of fluids and instruments during medical procedures, essential for accurate monitoring and precise manipulation.

-

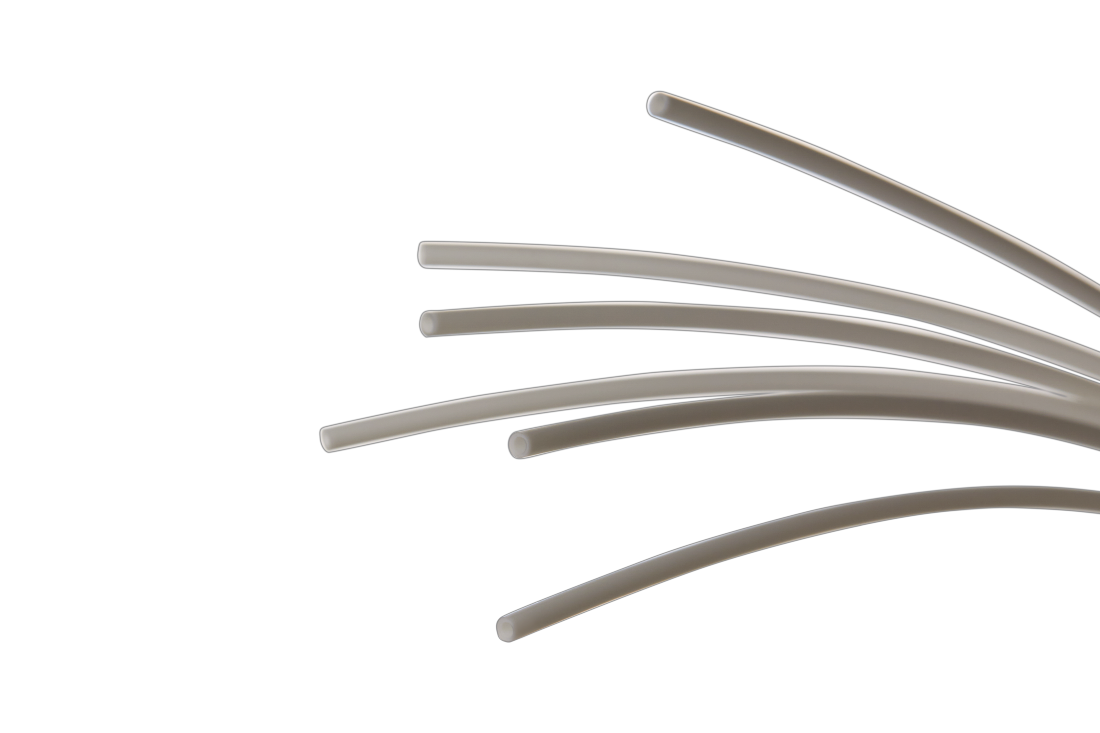

Pebax Tube

Pebax tubing is composed of a blend of thermoplastic elastomers, typically consisting of polyether and polyamide segments. This unique composition imparts Pebax tubing with its distinctive combination of flexibility, durability, and biocompatibility, making it an excellent choice for medical tubing applications.