Coating

Intelligent Manufacturing Production Equipment Coating comprises a sophisticated blend of materials meticulously formulated to provide exceptional protection and durability to industrial machinery. At its core are polymer resins, engineered to imbue the coating with robustness, resilience, and adhesive properties. These resins form the backbone of the coating, ensuring it adheres firmly to the surface of the machinery, resisting peeling, chipping, or delamination over time.

- Durability: The coating provides long-lasting protection against corrosion, scratches, and other forms of damage, prolonging the lifespan of machinery.

- Thickness: It is applied uniformly to ensure consistent coverage and protection across all surfaces of the equipment.

- Adhesion: The coating forms a strong bond with the surface of the machinery, preventing peeling or delamination.

- Temperature Resistance: It can withstand high temperatures encountered during manufacturing processes, maintaining its protective properties.

- Chemical Resistance: Resistant to various chemicals and solvents commonly used in industrial settings, ensuring the integrity of the coating.

- Automotive: Protecting machinery used in automotive manufacturing from corrosion and abrasion, ensuring the production of high-quality vehicles.

- Aerospace: Safeguarding aerospace manufacturing equipment from environmental factors and wear, maintaining the safety and reliability of aircraft components.

- Electronics: Enhancing the durability and performance of machinery used in electronics manufacturing, ensuring the production of reliable electronic devices.

- Medical Devices: Coating machinery involved in medical device manufacturing to maintain cleanliness, hygiene, and product quality in healthcare settings.

- Consumer Goods: Protecting machinery used in the production of consumer goods such as appliances and toys, ensuring the durability and longevity of everyday products.

Related products

-

Design

The composition of a coating typically comprises several key components meticulously balanced to achieve desired performance and application properties. At its core lies the binder, responsible for adhesion and film formation on the substrate. Pigments infuse color and other functional characteristics such as UV protection or corrosion resistance, while solvents or carriers facilitate application by dissolving or dispersing the binder and pigments. Additives are incorporated to fine-tune properties like viscosity, anti-foaming, or UV stability, ensuring optimal coating performance. Additionally, fillers enhance properties like hardness and abrasion resistance while serving as cost-effective extenders. Curing agents, in two-component systems, initiate crosslinking reactions with binders, yielding durable, resilient films. Each component’s precise formulation is tailored to specific application requirements, ensuring coatings deliver on durability, aesthetics, and protective capabilities across diverse industries and substrates.

-

Packaging

Intelligent Manufacturing Production Equipment Packaging is crafted using a combination of high-quality materials meticulously selected to provide robust protection for industrial machinery and equipment. Corrugated cardboard, foam inserts, and shock-absorbing materials are expertly integrated to ensure optimal cushioning and stability during handling and transit. Each packaging solution is custom-designed using advanced CAD software, tailoring the dimensions and features to suit the specific requirements of the equipment. Skilled technicians meticulously fabricate the packaging components, incorporating reinforced corners, cushioned interiors, and secure closures to maximize protection and stability.

-

Assembly

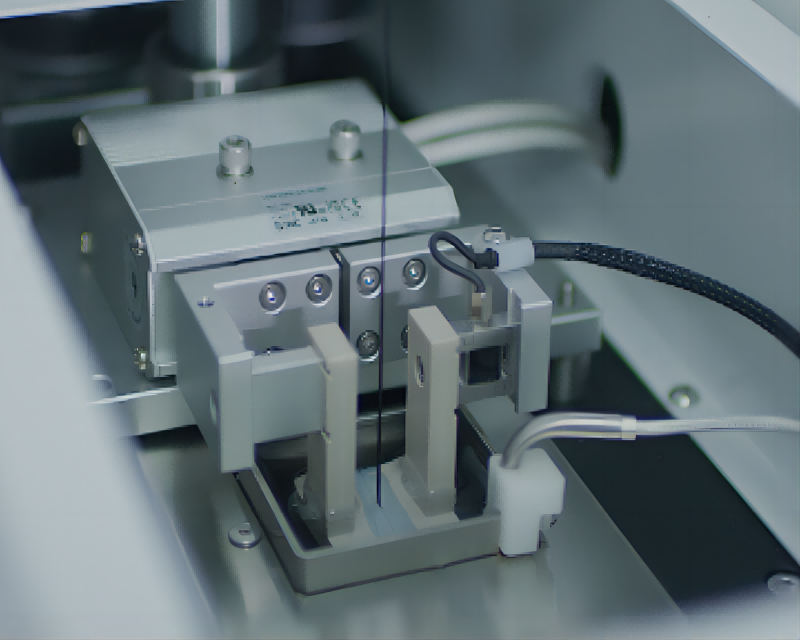

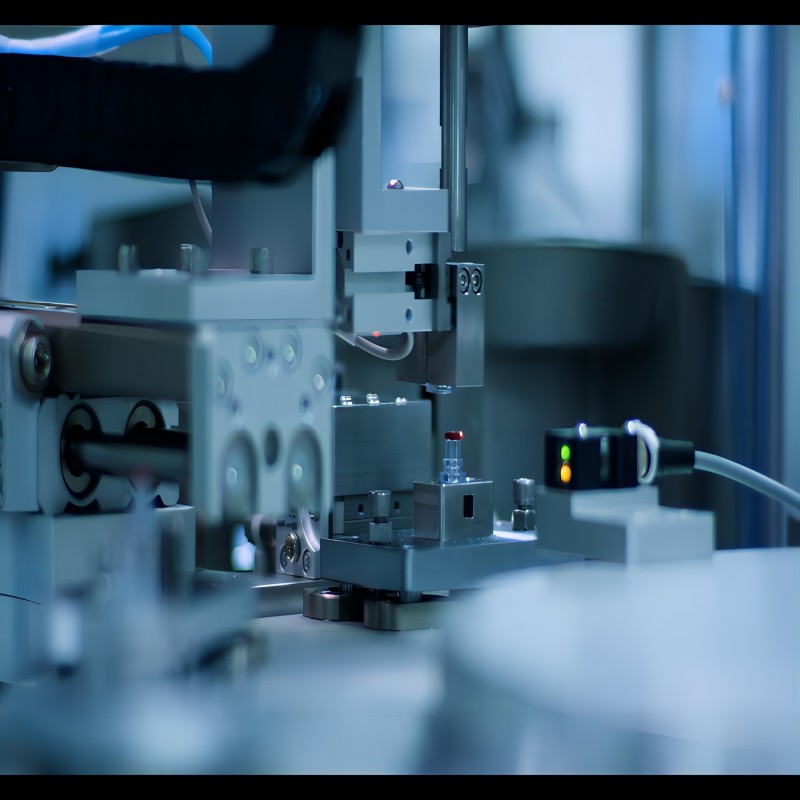

The assembly of Intelligent Manufacturing Production Equipment at Demax is a meticulously coordinated process that ensures precision, efficiency, and reliability. It begins with the fabrication of individual components, including robotic arms, conveyor systems, CNC machines, 3D printers, smart sensors, and IoT devices, each manufactured to the highest standards of quality and precision. Once the components are ready, our skilled technicians meticulously assemble them according to the detailed design specifications. Every step of the assembly process is carefully monitored to ensure proper alignment, integration, and functionality of each component.

-

Design

The composition of Intelligent Manufacturing Production Equipment designs by Demax is a meticulously orchestrated integration of cutting-edge technologies and specialized components. These designs typically include a combination of robotic arms, automated conveyor systems, CNC machines, 3D printers, smart sensors, and IoT devices. Each component is carefully selected and configured to optimize manufacturing processes, enhance productivity, and ensure the highest standards of quality and performance.