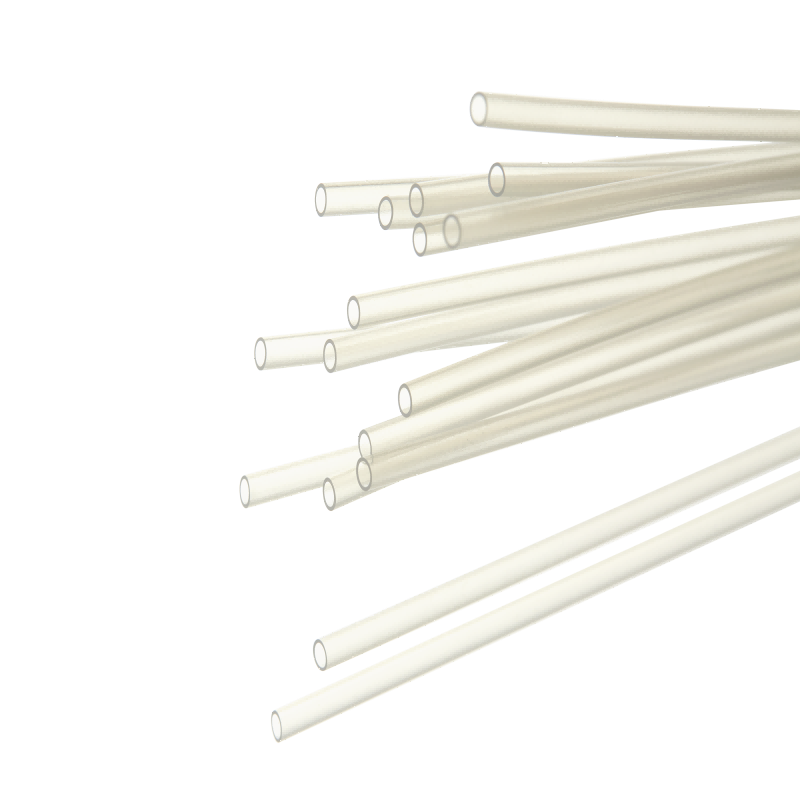

ETFE Tube

ETFE tubes manufactured by Demax are crafted from high-quality ethylene tetrafluoroethylene (ETFE) polymer.

This fluoropolymer material offers exceptional chemical resistance, mechanical strength, and biocompatibility, making it ideal for medical device applications.

ETFE tubes undergo precise extrusion processes to achieve consistent dimensions, smooth surfaces, and reliable performance in medical settings.

Features

- Good impact strength and abrasion resistance, superior to PTFE.

- Low coefficient of friction, smoother

- Better resistance to cut-through and stress cracking.

- ETFE maintains its mechanical properties at continuous operating temperatures exceeding 300 ºF (148 ºC).

Applications

ETFE tubes find wide-ranging applications across various medical specialties and procedures, including:- Catheterization:Used as a conduit for fluid delivery, guidewire passage, or balloon inflation in catheter-based interventions such as angioplasty, cardiac catheterization, and urinary catheterization.

- Endoscopy:Employed in endoscopic devices for gastrointestinal, respiratory, and urological procedures, providing channels for visualization, tissue sampling, and therapeutic interventions.

- Surgical Instruments: Integrated into surgical instruments for irrigation, suction, or illumination, enhancing functionality and precision during minimally invasive and open surgical procedures.

Technical Parameters

- Outer diameter: 0.5~10.0mm, tolerance: ±0.05mm

- Wall thickness: 0.03mm, tolerance: ±0.02mm

Related products

-

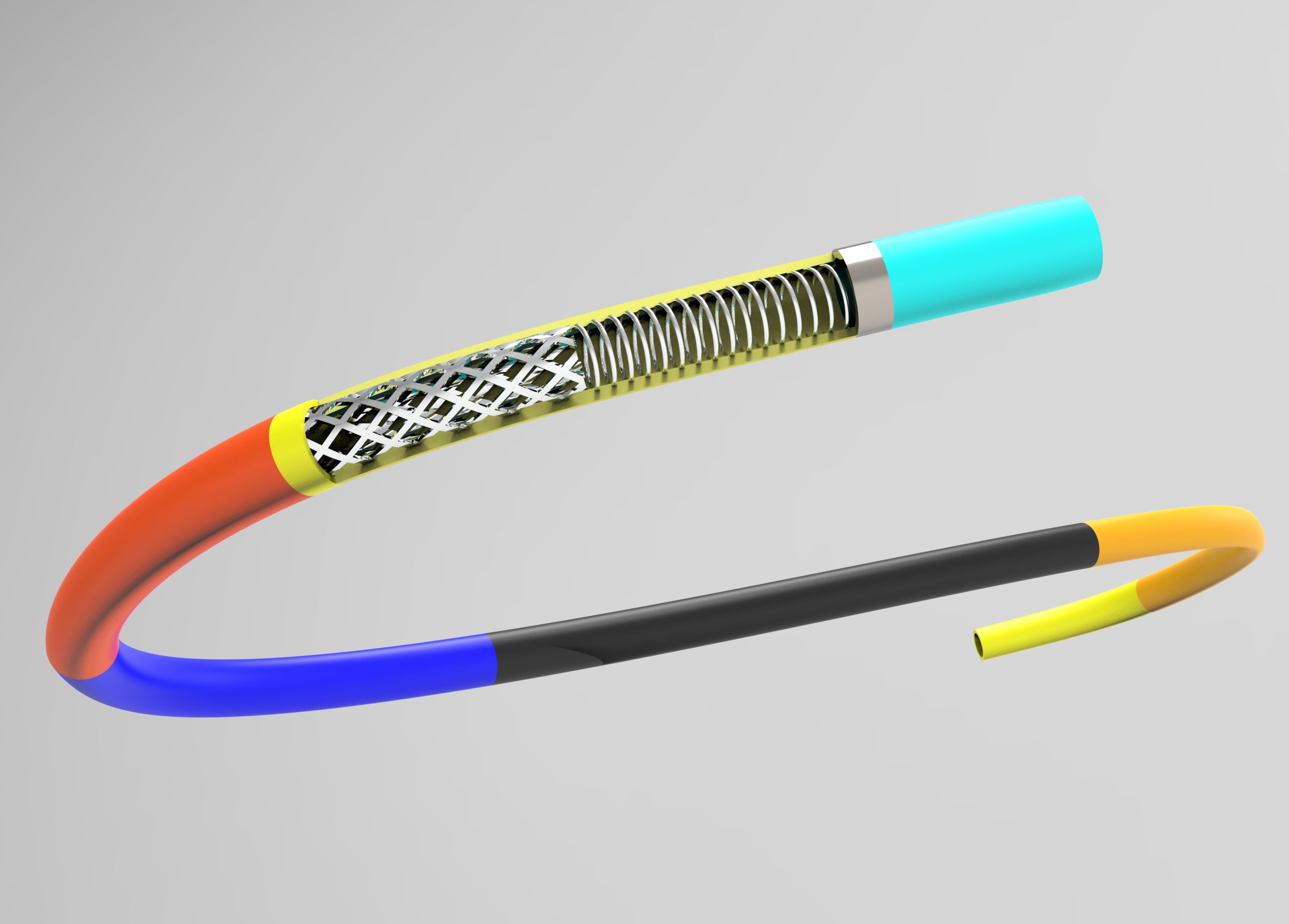

Braid & Coil Reinforcement Tube

The Demax Braid & Coil Reinforcement Tube is an innovative medical device designed to provide enhanced strength and flexibility for a wide range of medical applications. Crafted with precision and utilizing advanced materials, this reinforced tubing offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

-

FEP Heat Shrink Tube

The FEP Heat Shrink Tube boasts a composition rooted in fluorinated ethylene propylene (FEP), a thermoplastic polymer renowned for its exceptional properties in medical applications.

FEP exhibits a unique combination of characteristics that make it ideally suited for medical tubing. Its molecular structure imparts remarkable clarity to the tubing, allowing for optimal visualization of fluids and instruments during medical procedures, essential for accurate monitoring and precise manipulation.

-

Pebax Tube

Pebax tubing is composed of a blend of thermoplastic elastomers, typically consisting of polyether and polyamide segments. This unique composition imparts Pebax tubing with its distinctive combination of flexibility, durability, and biocompatibility, making it an excellent choice for medical tubing applications.

-

TPU Tube

Demax TPU tubes are meticulously crafted from Thermoplastic Polyurethane (TPU), a premium synthetic polymer renowned for its exceptional elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This composition ensures the tubes’ longevity and reliability, even in the most demanding conditions. Demax’s commitment to quality extends to every aspect of their manufacturing process, from sourcing the finest materials to employing advanced production techniques. The result is a TPU tube that meets stringent industry standards, providing customers with confidence and peace of mind in their critical applications. Whether in medical procedures, laboratory experiments, or industrial processes, Demax TPU tubes deliver unmatched performance and durability, making them the preferred choice for professionals across various sectors.