Extra Stiff Guidewire

The Demax Extra Stiff Guidewire is meticulously crafted from high-quality materials to ensure exceptional performance and reliability. Composed of a PTFE-coated stainless steel core wire and a PTFE-coated spring, this guide wire offers optimal strength, flexibility, and maneuverability for navigating through challenging anatomical structures with ease. Additionally, some models feature a radiopaque spring, enhancing visibility under fluoroscopy for precise positioning within the target area. This advanced composition guarantees superior durability, biocompatibility, and performance, making the Demax Extra Stiff Guidewire an indispensable tool for healthcare professionals in various medical procedures.

- Diameter: The Demax Extra Stiff Guidewire features a diameter of 0.035 inches, providing the ideal balance of rigidity and flexibility for navigating through tough lesions and complex anatomical pathways.

- Length: Customization is available, with lengths ranging from 90 cm to 300 cm, ensuring compatibility with a wide range of procedural requirements and anatomical variations.

- Stiffness: Engineered to provide exceptional rigidity and resistance to bending, allowing for precise navigation through tortuous anatomical structures.

- Diameter Options: Available in a range of diameters to accommodate various procedural requirements and anatomical variations.

- Material: Crafted from high-quality stainless steel or nitinol alloy, renowned for their strength, durability, and biocompatibility.

- Tip Design: Designed with a radiopaque tip for enhanced visibility under fluoroscopy, ensuring accurate positioning within the target area.

- Length: Customizable lengths to suit the specific procedural needs and anatomical considerations of each patient.

- Interventional Cardiology: Navigating through calcified coronary arteries during percutaneous coronary interventions (PCI), such as angioplasty and stenting.

- Peripheral Interventions: Crossing tough lesions and navigating through tortuous peripheral vessels in procedures like angioplasty, atherectomy, and thrombectomy.

- Neurointerventions: Accessing intricate cerebral vasculature during neurovascular procedures such as embolization or coil placement for aneurysm treatment.

- Interventional Radiology: Guiding catheter placement and therapeutic devices in procedures such as embolization, tumor ablation, and vascular recanalization.

Related products

-

Peripheral Vascular Guidewire

The Demax Peripheral Vascular Guidewire is meticulously crafted using high-quality materials such as stainless steel or tungsten-containing polyurethane tubes, surface coated with hydrophilic coating, known for their exceptional strength, flexibility, and biocompatibility. These materials undergo precision manufacturing processes to achieve the desired diameter, length, and mechanical properties required for effective vascular navigation. The guidewire is coated with a hydrophilic coating to enhance lubricity and reduce friction, ensuring smooth advancement through vascular pathways. With its advanced design and composition, the Demax Peripheral Vascular Guidewire promises to revolutionize peripheral vascular interventions. It offers healthcare professionals a reliable and versatile tool for navigating complex vascular anatomy and delivering optimal patient care.

-

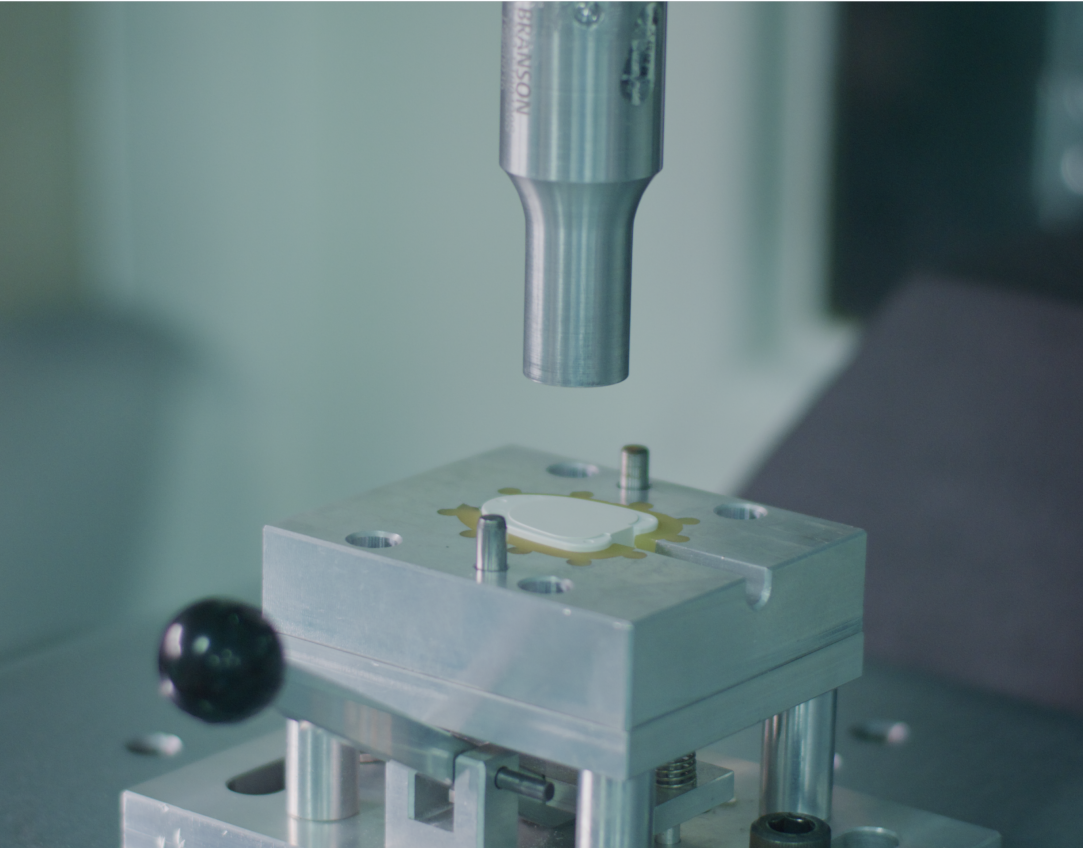

Guidewire Welding

The composition of guidewire assemblies produced by Demax is meticulously crafted to ensure superior performance and reliability. These assemblies typically consist of high-quality materials such as stainless steel, nitinol, or specialty alloys, chosen for their mechanical strength, corrosion resistance, and biocompatibility where applicable, particularly in medical applications. Additionally, advanced welding techniques, including plasma welding, laser welding, and PTCA wire brazing, are employed to securely fuse the components together.

-

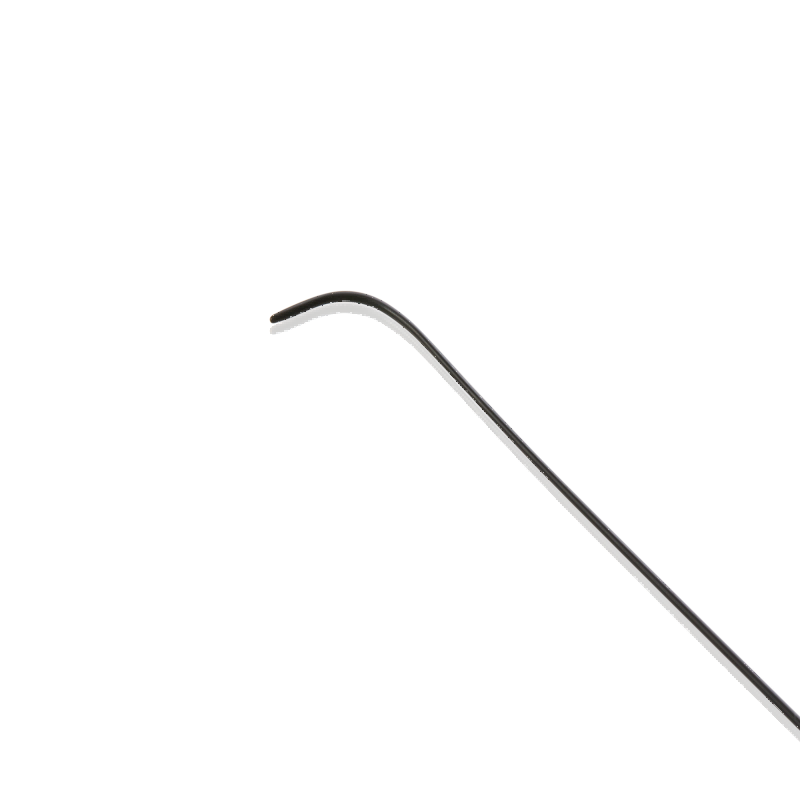

Hydrophilic Guidewire

The composition of Hydrophilic Coated Guidewires typically consists of a core material, such as stainless steel or nitinol, surrounded by a hydrophilic polymer coating. Stainless steel provides the necessary rigidity and structural integrity to the guidewire, enabling it to withstand the forces encountered during navigation through the body. On the other hand, nitinol, a shape-memory alloy, offers flexibility and elasticity, allowing the guidewire to adapt to the contours of anatomical structures without sacrificing durability.

The hydrophilic coating, usually composed of PTFE or a similar material, serves as a lubricious layer that reduces friction and enhances the guidewire’s ability to glide smoothly through the vasculature or other bodily passages. This coating undergoes a specialized manufacturing process to ensure uniformity and durability, enabling the guidewire to maintain its hydrophilic properties throughout the duration of the procedure.

-

Angiography Guidewire

Angiography guidewires manufactured by Demax are meticulously crafted from high-grade materials such as stainless steel or nitinol. These materials offer excellent mechanical properties, including flexibility, durability, and kink resistance, essential for navigating through tortuous vessels and performing intricate vascular procedures with precision. Additionally, some guidewires feature hydrophilic coatings to enhance lubricity and minimize friction during navigation, further improving procedural success rates and patient comfort. With their advanced composition and precision engineering, Demax angiography guidewires set the standard for excellence in vascular intervention tools, empowering healthcare professionals to deliver superior care to their patients.