Guidewire Welding

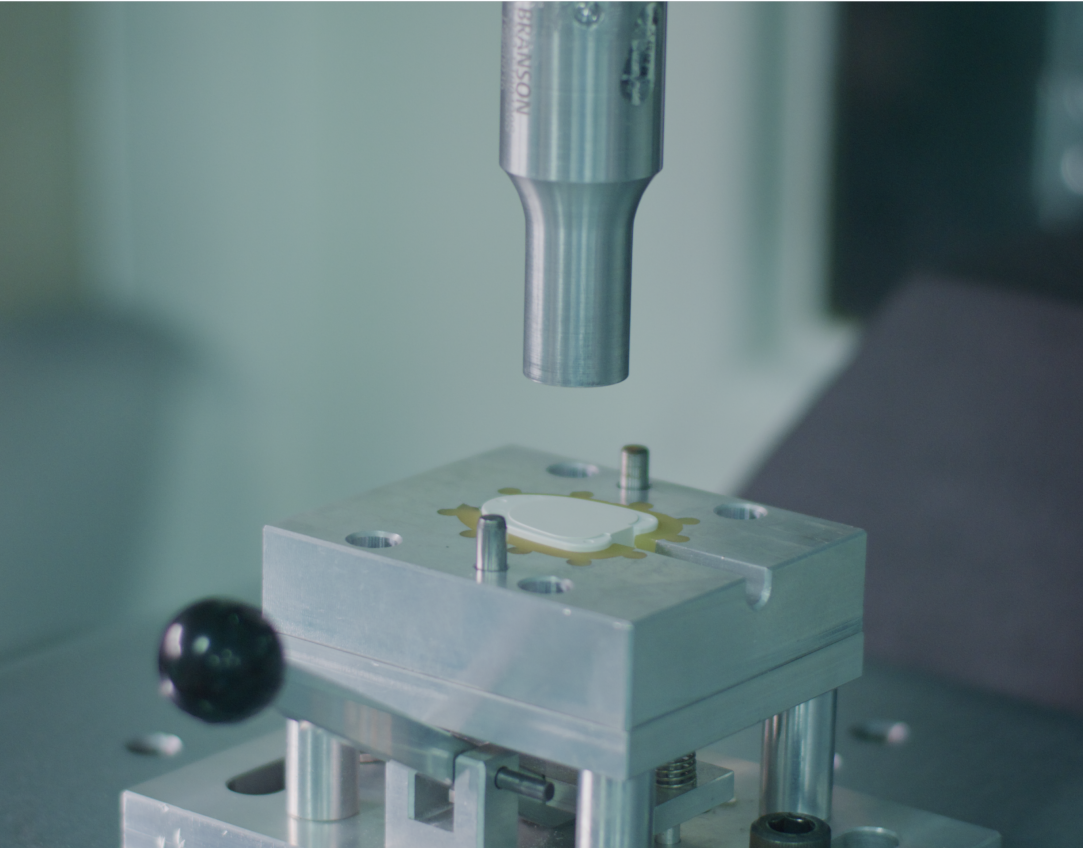

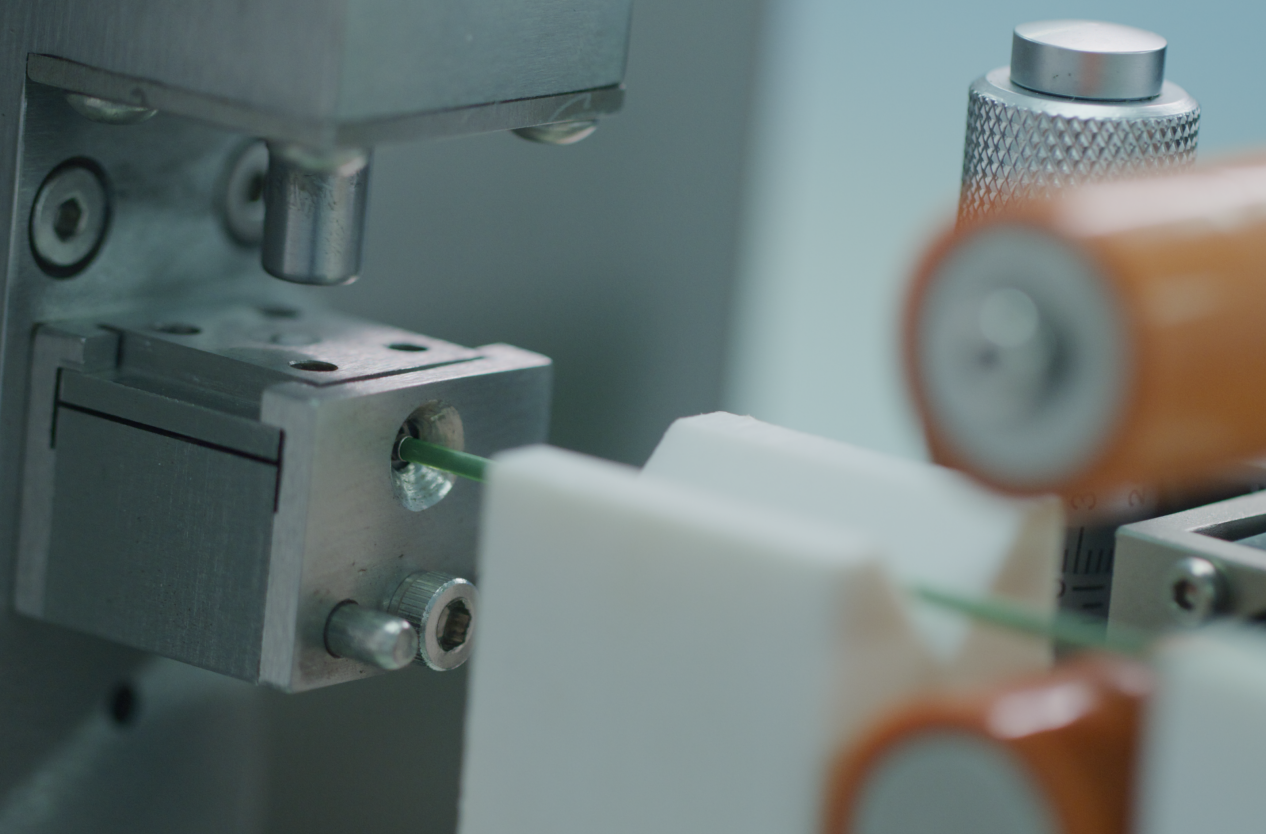

The composition of guidewire assemblies produced by Demax is meticulously crafted to ensure superior performance and reliability. These assemblies typically consist of high-quality materials such as stainless steel, nitinol, or specialty alloys, chosen for their mechanical strength, corrosion resistance, and biocompatibility where applicable, particularly in medical applications. Additionally, advanced welding techniques, including plasma welding, laser welding, and PTCA wire brazing, are employed to securely fuse the components together.

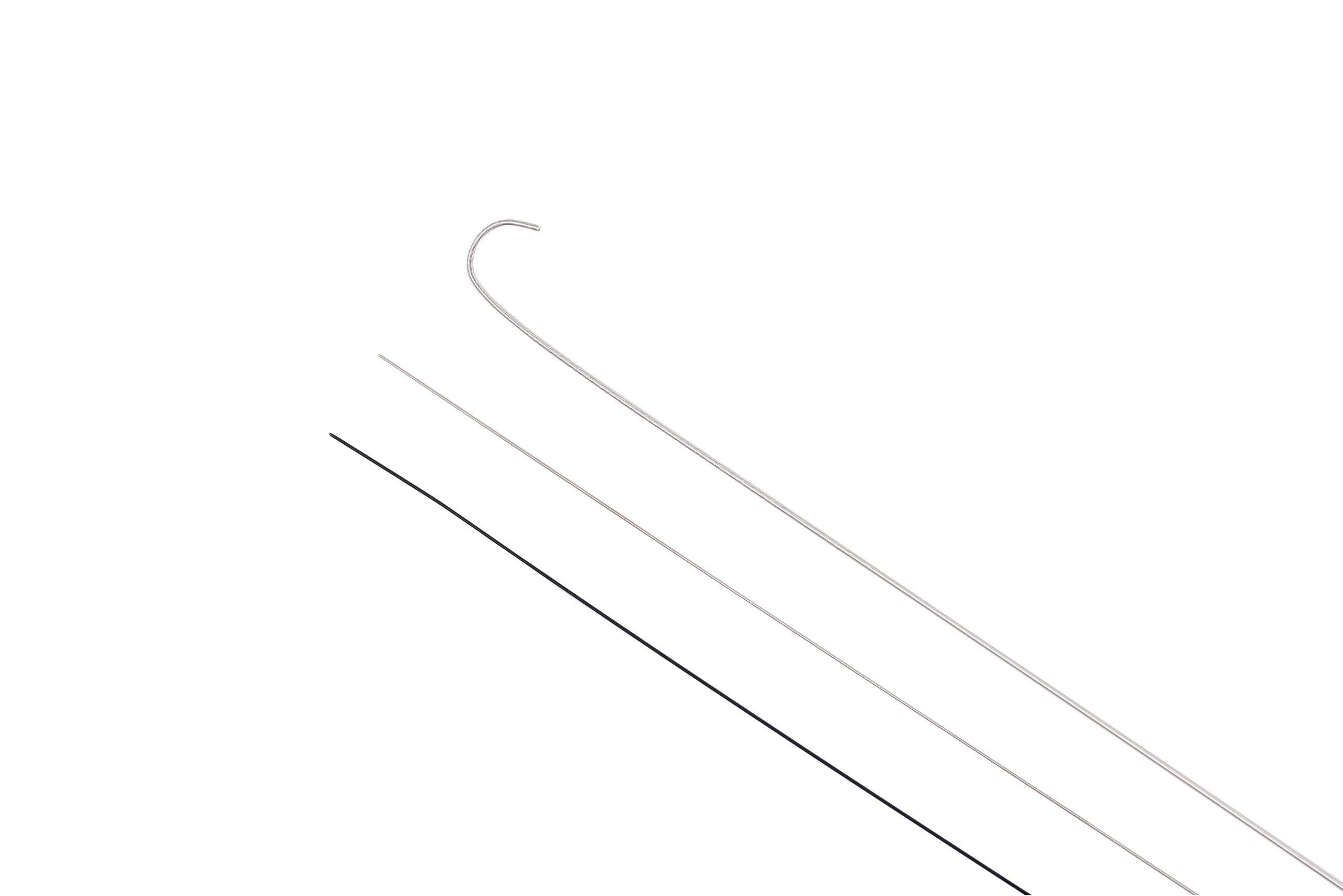

- Wire Diameter Range: From ultra-fine 0.014″ to 0.038″, Demax Guidewire Welding accommodates a wide range of wire diameters, ensuring versatility for diverse applications.

- Welding Techniques: Demax offers a comprehensive range of welding techniques, including guide wire welding, plasma welding, laser welding, and PTCA wire brazing, providing flexibility to meet specific assembly requirements.

What is it?

Guidewire welding is a specialized technique for joining two or more thin wires used in various medical devices, particularly guidewires. These delicate wires navigate through blood vessels during minimally invasive procedures like angioplasty and stenting, requiring strong and reliable connections.

Demax Guidewire Welding represents the pinnacle of precision and reliability in the manufacturing of guidewire assemblies. With a commitment to excellence and innovation, Demax utilizes advanced welding technologies to produce high-quality guide wire assemblies tailored to the unique needs of various industries and applications.

- Medical Devices: Guidewire assemblies produced by Demax are used in minimally invasive medical procedures such as angioplasty, endoscopy, and neurosurgery, where precision and reliability are paramount.

- Aerospace: Demax guidewire assemblies play a critical role in aerospace applications, providing support, alignment, and reinforcement in aircraft components and systems.

- Automotive: Guidewire assemblies manufactured by Demax are utilized in automotive manufacturing processes for alignment, positioning, and assembly operations, contributing to the efficiency and quality of vehicle production.

- Electronics: Demax guidewire assemblies are integral to the assembly of electronic devices, providing structural support and connectivity in components such as sensors, actuators, and circuit boards.

Related products

Peripheral Vascular Guidewire

The Demax Peripheral Vascular Guidewire is meticulously crafted using high-quality materials such as stainless steel or tungsten-containing polyurethane tubes, surface coated with hydrophilic coating, known for their exceptional strength, flexibility, and biocompatibility. These materials undergo precision manufacturing processes to achieve the desired diameter, length, and mechanical properties required for effective vascular navigation. The guidewire is coated with a hydrophilic coating to enhance lubricity and reduce friction, ensuring smooth advancement through vascular pathways. With its advanced design and composition, the Demax Peripheral Vascular Guidewire promises to revolutionize peripheral vascular interventions. It offers healthcare professionals a reliable and versatile tool for navigating complex vascular anatomy and delivering optimal patient care.

Puncture Guidewire

Puncture Guidewire is composed of a stainless steel core wire and a stainless steel winding wire. The core wire provides stiffness and support for navigating through anatomical pathways, while the winding wire enhances flexibility and maneuverability. This composition ensures the guide wire’s durability and reliability during minimally invasive procedures, allowing healthcare professionals to navigate with precision and achieve successful outcomes for their patients.

Spring Winding

The composition of springs produced with Demax Spring Winding varies depending on the application requirements. These springs can be wound from a variety of materials, including high-carbon steel, stainless steel, titanium, and specialty alloys, chosen for their mechanical properties and corrosion resistance. Additionally, depending on the application, springs may undergo surface treatments such as heat treatment, shot peening, or coating to enhance durability, fatigue resistance, and performance in challenging environments

Core wire Grinding

The core wire itself is typically made from high-grade stainless steel for strength and corrosion resistance, or Nitinol, a shape-memory alloy offering superelasticity crucial for flexible and kink-resistant guidewires and stents. Depending on the specific device needs, other specialty alloys like platinum, tantalum, and cobalt-chromium might be used for their unique properties. Additionally, the grinding process can be tailored to achieve specific surface finishes and the core wire might receive further coatings to enhance its properties and functionality within the final medical device.