Hook Forming

Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, chosen for their exceptional mechanical properties, corrosion resistance, and biocompatibility. These materials undergo precise shaping processes to achieve intricate hook configurations tailored to specific medical device applications. With our commitment to quality and precision, Demax ensures that hook-formed components meet the rigorous demands of medical device manufacturing, contributing to the advancement of healthcare worldwide.

- Materials: Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, ensuring durability, flexibility, and biocompatibility in medical device applications.

- Hook Configurations: Our hook forming capabilities encompass a wide range of configurations, including J-hooks, C-hooks, and complex multi-dimensional shapes, tailored to meet the specific requirements of diverse medical devices and procedures.

- Size Range: Demax offers hook forming services for components ranging in size from micro-scale hooks for minimally invasive procedures to larger hooks for surgical instruments, accommodating a broad spectrum of medical device applications.

- Tolerance: Precision manufacturing processes and stringent quality control measures ensure tight tolerances, guaranteeing consistency and accuracy in hook configurations essential for optimal device performance.

- Guidewires: Formed hooks enable precise navigation and steerability of guidewires during vascular procedures such as angiography and angioplasty.

- Catheters: Hooks incorporated into catheter designs facilitate device placement, manipulation, and anchoring within the body during diagnostic and therapeutic interventions.

- Surgical Instruments: Hook-formed components enhance the functionality of surgical instruments by providing secure grip, precise control, and improved tissue manipulation during surgical procedures.

- Endoscopic Devices: Hooks enable the advancement and positioning of endoscopic devices within the gastrointestinal or respiratory tract, aiding in visualization and treatment of pathological conditions.

- Orthopedic Instruments: Hooks are utilized in orthopedic instruments for soft tissue retraction, tendon manipulation, and bone reduction during orthopedic surgeries.

Related products

-

Coating

Precision Medical Tubing Services Coating from Demax involves the application of specialized coatings onto medical-grade tubing substrates to enhance their performance and functionality. These coatings may include hydrophilic coatings, hydrophobic coatings, antimicrobial coatings, drug-eluting coatings, and more, depending on the specific requirements of the medical device and application. The coating materials are carefully selected for their biocompatibility, adhesion properties, and compatibility with the substrate material to ensure optimal performance and safety. Each coating is applied using precise coating techniques to achieve uniform coverage and consistent thickness, resulting in medical tubing with enhanced lubricity, biocompatibility, and other desirable properties.

-

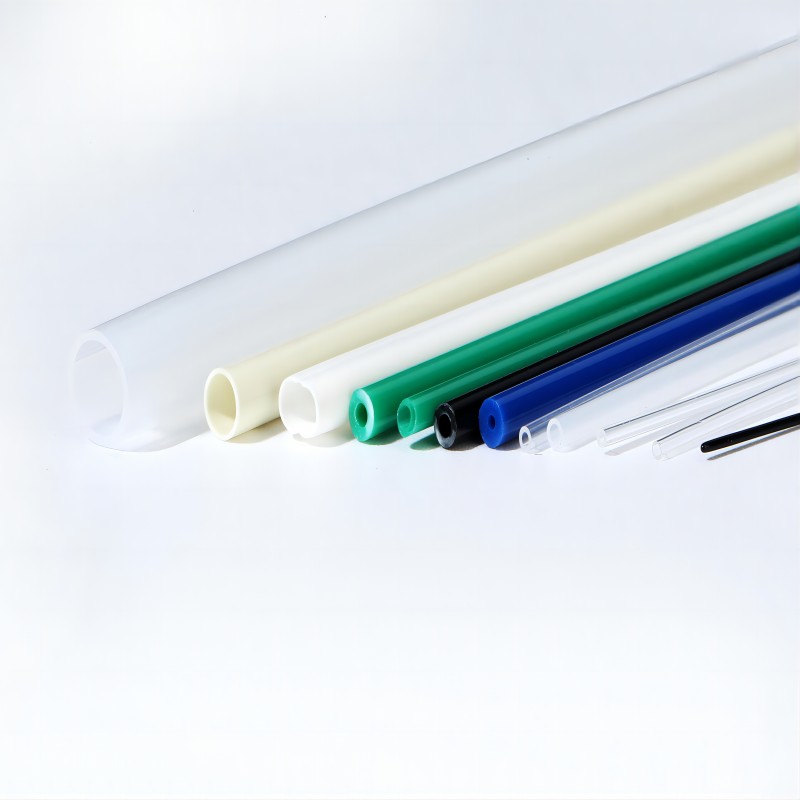

Flaring

Precision Medical Tubing Services Flaring involves the precise modification of medical-grade tubing materials to create flares and expansions. The composition of the tubing used in this process varies depending on the specific requirements of the medical device and the application. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

-

PP Tube

The PP Tube is meticulously crafted from high-quality polypropylene, a thermoplastic polymer renowned for its exceptional chemical resistance, durability, and biocompatibility. This composition ensures that the tube is safe for use within the body and can withstand the rigors of medical procedures without compromising patient safety or device performance. Employing state-of-the-art manufacturing techniques, Demax ensures uniformity in dimensions and performance, producing PP Tubes that meet the highest standards of quality and reliability. With Demax’s PP Tubes, healthcare professionals can perform medical procedures with confidence, knowing that they have a dependable and effective tool at their disposal to deliver optimal patient care.

-

Guiding Catheter

Guiding catheters are typically composed of biocompatible materials such as polyurethane or nylon, chosen for their flexibility, durability, and compatibility with bodily tissues. The catheter shaft is reinforced with braided or coiled wires to provide structural support and torqueability while maintaining flexibility for navigation through tortuous vascular anatomy. Soft, atraumatic tips minimize trauma to blood vessels during insertion and positioning. Radiopaque markers or bands incorporated into the catheter shaft enhance visibility under fluoroscopy or other imaging modalities, allowing for precise navigation and positioning during procedures. Demax’s guiding catheters are engineered with advanced materials and design features to optimize performance and safety, ensuring successful outcomes in a wide range of interventional procedures.