Laminating & Welding

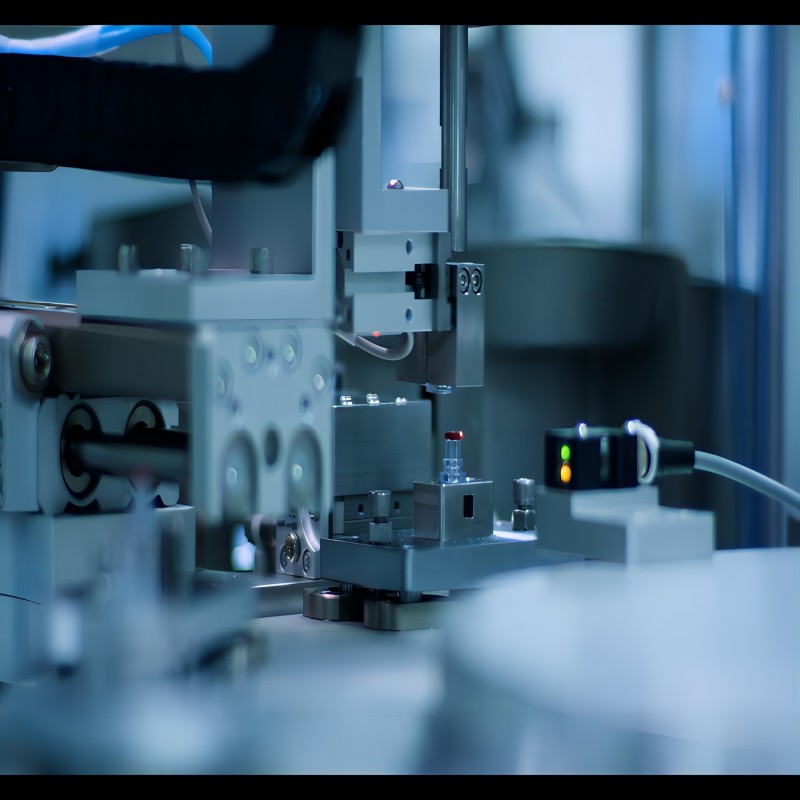

The composition of Intelligent Manufacturing Production Equipment Laminating & Welding encompasses a combination of key components, including robotic arms or manipulators for precise material handling, advanced welding technologies such as laser or ultrasonic welding for high-speed and accurate bonding, sophisticated control systems for regulating process parameters, automatic material feeding and alignment systems for streamlined production, integrated quality inspection mechanisms for ensuring product quality, and customizable configurations to adapt to various materials and production requirements. Together, these components work in harmony to enable efficient and reliable lamination and welding processes, contributing to the production of high-quality products across diverse industries.

- Tube Stretching Machine: With 10 channels, this machine guides the inner layer of catheters for stretching.

- Catheter Heating Machine: Operating with 8 channels arranged in 4 groups, it offers the flexibility of individual or simultaneous lamination within each group.

- Hot Air Heating Machine: Ensures uniform heating distribution and serves as a cost-effective alternative to imported equipment.

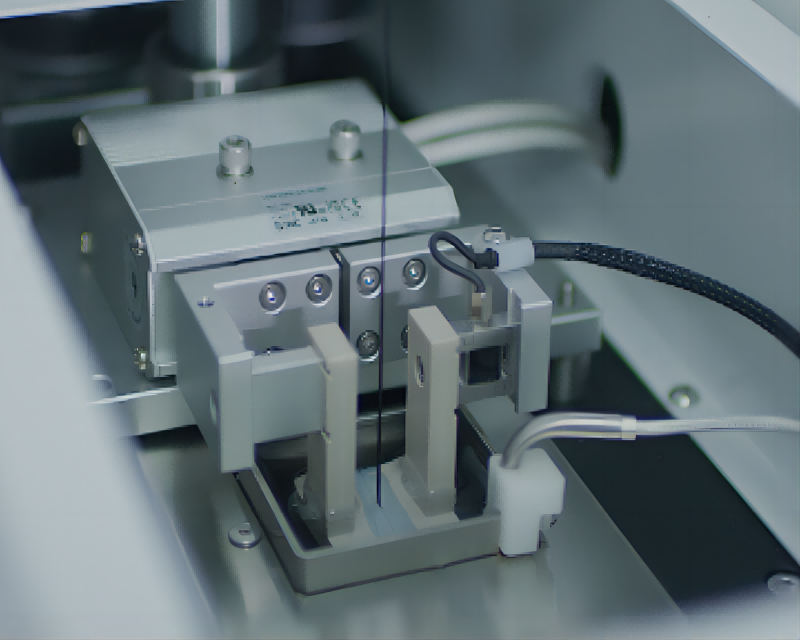

- Braided Conduit Automatic Welding Machine: Initially employs manual welding at the first point, followed by seamless transition to automatic welding for subsequent points.

- Automatic Ultrasonic Welding Machine: Automates assembly by facilitating placement and welding of hemostatic valves, with automatic feeding of back covers.

- Automotive manufacturing: Bonding and welding of automotive components such as body panels, chassis parts, and interior trim.

- Electronics manufacturing: Assembly of electronic devices and circuit boards using precision bonding and welding techniques.

- Aerospace industry: Fabrication of aircraft components and structures requiring high-strength bonding and welding.

- Medical device manufacturing: Production of medical implants, devices, and instruments with biocompatible materials and precise bonding requirements.

- Textile industry: Laminating and welding of fabrics and textiles for applications such as clothing, upholstery, and technical textiles.

Related products

-

Design

The composition of a coating typically comprises several key components meticulously balanced to achieve desired performance and application properties. At its core lies the binder, responsible for adhesion and film formation on the substrate. Pigments infuse color and other functional characteristics such as UV protection or corrosion resistance, while solvents or carriers facilitate application by dissolving or dispersing the binder and pigments. Additives are incorporated to fine-tune properties like viscosity, anti-foaming, or UV stability, ensuring optimal coating performance. Additionally, fillers enhance properties like hardness and abrasion resistance while serving as cost-effective extenders. Curing agents, in two-component systems, initiate crosslinking reactions with binders, yielding durable, resilient films. Each component’s precise formulation is tailored to specific application requirements, ensuring coatings deliver on durability, aesthetics, and protective capabilities across diverse industries and substrates.

-

Packaging

Intelligent Manufacturing Production Equipment Packaging is crafted using a combination of high-quality materials meticulously selected to provide robust protection for industrial machinery and equipment. Corrugated cardboard, foam inserts, and shock-absorbing materials are expertly integrated to ensure optimal cushioning and stability during handling and transit. Each packaging solution is custom-designed using advanced CAD software, tailoring the dimensions and features to suit the specific requirements of the equipment. Skilled technicians meticulously fabricate the packaging components, incorporating reinforced corners, cushioned interiors, and secure closures to maximize protection and stability.

-

Coating

Intelligent Manufacturing Production Equipment Coating comprises a sophisticated blend of materials meticulously formulated to provide exceptional protection and durability to industrial machinery. At its core are polymer resins, engineered to imbue the coating with robustness, resilience, and adhesive properties. These resins form the backbone of the coating, ensuring it adheres firmly to the surface of the machinery, resisting peeling, chipping, or delamination over time.

-

Assembly

The assembly of Intelligent Manufacturing Production Equipment at Demax is a meticulously coordinated process that ensures precision, efficiency, and reliability. It begins with the fabrication of individual components, including robotic arms, conveyor systems, CNC machines, 3D printers, smart sensors, and IoT devices, each manufactured to the highest standards of quality and precision. Once the components are ready, our skilled technicians meticulously assemble them according to the detailed design specifications. Every step of the assembly process is carefully monitored to ensure proper alignment, integration, and functionality of each component.