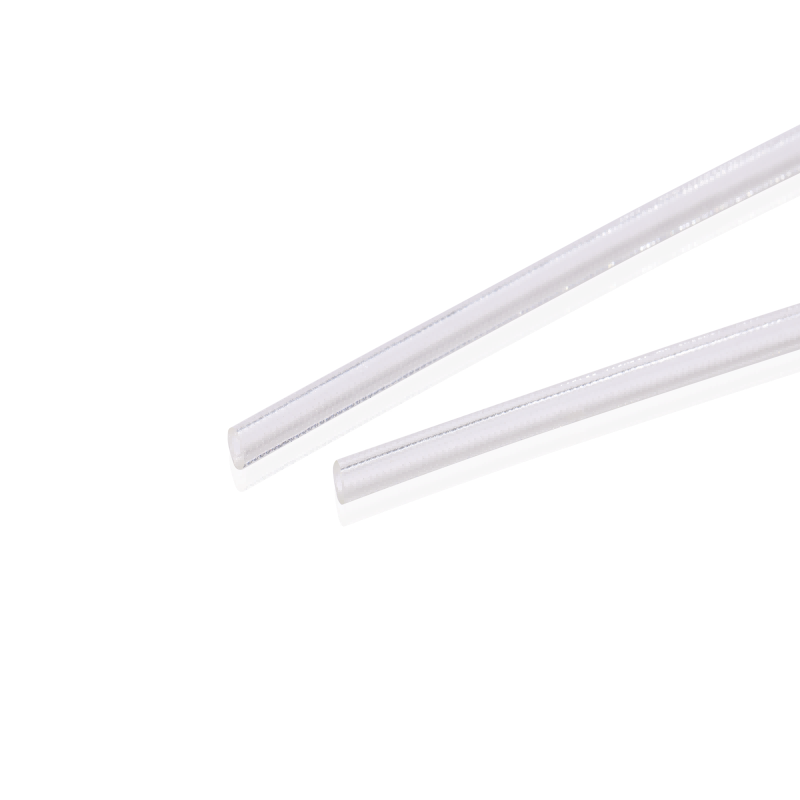

FEP Heat Shrink Tube

The FEP Heat Shrink Tube boasts a composition rooted in fluorinated ethylene propylene (FEP), a thermoplastic polymer renowned for its exceptional properties in medical applications.

FEP exhibits a unique combination of characteristics that make it ideally suited for medical tubing. Its molecular structure imparts remarkable clarity to the tubing, allowing for optimal visualization of fluids and instruments during medical procedures, essential for accurate monitoring and precise manipulation.

Features

- Lower heat shrink temperature:FEP heat shrink tubing has a lower heat shrink temperature than other fluorinated heat shrink tubing, such as PTFE, PFA

- It has better flexibility, light transmittance and high lubricity than PFA.

- The recommended shrinking temperature is 80℃-240℃. The shrinking temperature and shrinking time vary depending on the design.

- Demaxcan provide FEP heat shrink tubing with shrinkage ratios of 1.3:1, 1.6:1 and 1.8:1.

Applications

Welding of Guiding Catheter, Angiography Catheter, Micro Catheter, Guiding Sheath, Distal Access Catheter: laser welding, hot air welding, heat fusion welding, etc.Technical Parameters

- Minimum Inner Diameter Before Shrinkage:79-4.78(mm)

- Maximum Inner Diameter Before Shrinkage:69-2.92(mm)

- Tube Wall Thickness After Shrinkage:2±0.05,0.23±0.05,0.25±0.08, 0.28±0.1(mm)

- Shrink Temperature 200-230℃

- Shrink Ratios 3:1,1.6:1, 1.8:1

- Concentricity ≥90%

- Biocompatibility Conforms to ISO10993

Related products

-

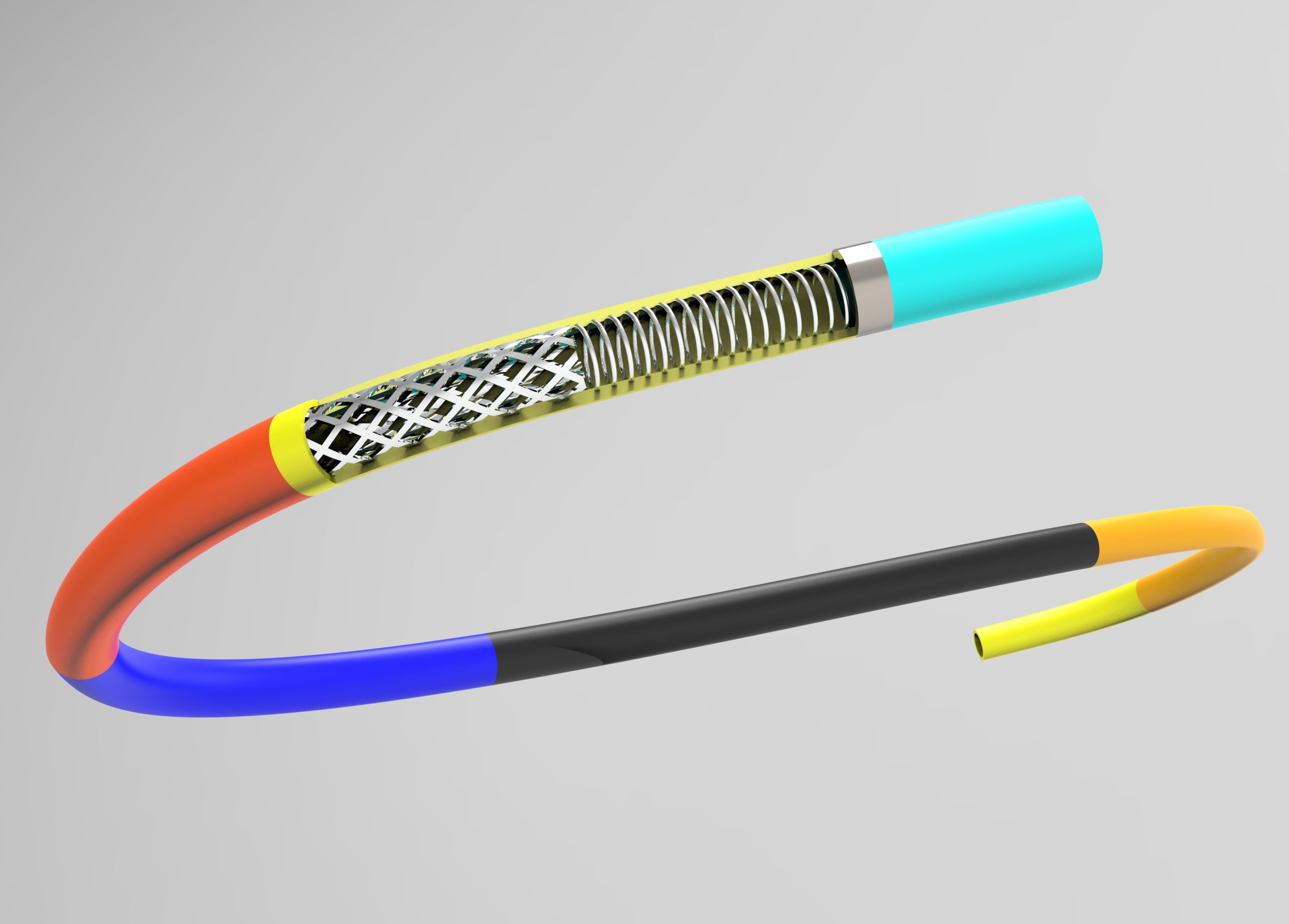

Stent delivery system Braided catheter

Establishing an access channel forinstruments to enter the body

Customizable in various sizes to meet different lesion requirements

-

PU Braided Tube

The Demax PU Braided Tube is constructed using polyurethane (PU), a high-performance polymer known for its excellent mechanical properties and chemical resistance. This tubing is reinforced with a braided layer, providing enhanced strength and resistance to kinking and collapse. It is manufactured to meet the stringent standards of the medical industry, ensuring biocompatibility and safety for patient use. The tubing is free from latex, phthalates, and other harmful substances, minimizing the risk of adverse reactions or complications.

-

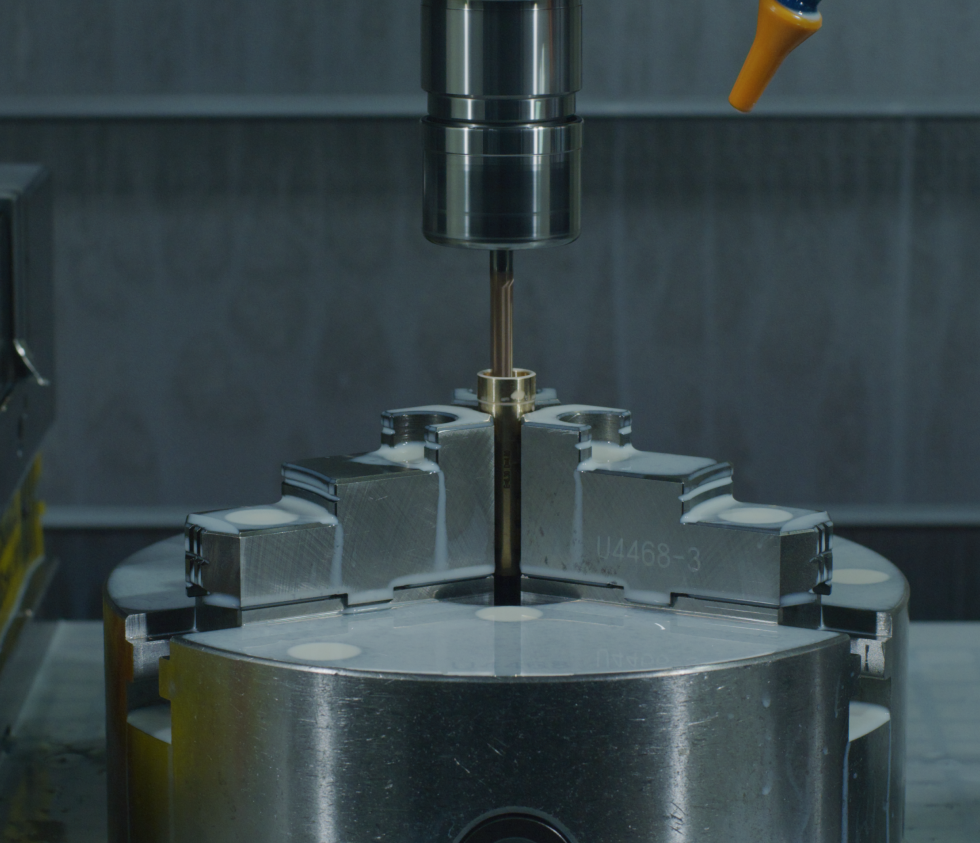

Hook Forming

Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, chosen for their exceptional mechanical properties, corrosion resistance, and biocompatibility. These materials undergo precise shaping processes to achieve intricate hook configurations tailored to specific medical device applications. With our commitment to quality and precision, Demax ensures that hook-formed components meet the rigorous demands of medical device manufacturing, contributing to the advancement of healthcare worldwide.

-

TPU Tube

Demax TPU tubes are meticulously crafted from Thermoplastic Polyurethane (TPU), a premium synthetic polymer renowned for its exceptional elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This composition ensures the tubes’ longevity and reliability, even in the most demanding conditions. Demax’s commitment to quality extends to every aspect of their manufacturing process, from sourcing the finest materials to employing advanced production techniques. The result is a TPU tube that meets stringent industry standards, providing customers with confidence and peace of mind in their critical applications. Whether in medical procedures, laboratory experiments, or industrial processes, Demax TPU tubes deliver unmatched performance and durability, making them the preferred choice for professionals across various sectors.