Packaging

Intelligent Manufacturing Production Equipment Packaging is crafted using a combination of high-quality materials meticulously selected to provide robust protection for industrial machinery and equipment. Corrugated cardboard, foam inserts, and shock-absorbing materials are expertly integrated to ensure optimal cushioning and stability during handling and transit. Each packaging solution is custom-designed using advanced CAD software, tailoring the dimensions and features to suit the specific requirements of the equipment. Skilled technicians meticulously fabricate the packaging components, incorporating reinforced corners, cushioned interiors, and secure closures to maximize protection and stability.

- Customized Design: Tailored packaging solutions designed to accommodate the specific dimensions and weight of each piece of equipment.

- Materials: High-quality materials such as corrugated cardboard, foam inserts, and shock-absorbing materials are utilized to provide optimal protection.

- Durability: Robust construction and secure closures ensure the durability and integrity of the packaging during handling and transit.

- Shock Absorption: Cushioned interiors and shock-absorbing materials minimize the risk of damage from impacts and vibrations during transportation.

- Weather Resistance: Weather-resistant coatings and seals protect the equipment from moisture, dust, and other environmental elements during storage and transit.

- Ease of Handling: Ergonomic design features and integrated handles facilitate safe and efficient handling of the packaged equipment.

- Automotive Industry: Protects precision machinery during transit, ensuring the uninterrupted production of vehicle components like engines and transmissions.

- Aerospace Sector: Safeguards sensitive equipment used in aircraft manufacturing, such as avionics systems and engine components, maintaining the safety and integrity of the aircraft.

- Electronics Manufacturing: Shields delicate machinery like semiconductor manufacturing tools and circuit board assembly machines from electrostatic discharge and physical damage, ensuring the reliability of electronic devices.

- Medical Device Manufacturing: Ensures safe handling and transportation of medical equipment such as diagnostic machines and surgical instruments, maintaining sterility and preventing contamination for high-quality medical products.

Related products

-

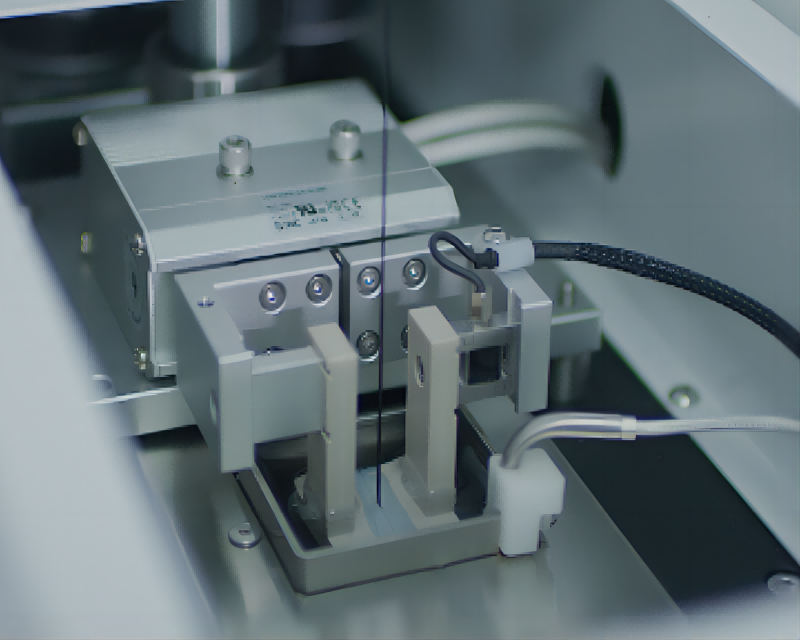

Laminating & Welding

The composition of Intelligent Manufacturing Production Equipment Laminating & Welding encompasses a combination of key components, including robotic arms or manipulators for precise material handling, advanced welding technologies such as laser or ultrasonic welding for high-speed and accurate bonding, sophisticated control systems for regulating process parameters, automatic material feeding and alignment systems for streamlined production, integrated quality inspection mechanisms for ensuring product quality, and customizable configurations to adapt to various materials and production requirements. Together, these components work in harmony to enable efficient and reliable lamination and welding processes, contributing to the production of high-quality products across diverse industries.

-

Coating

Intelligent Manufacturing Production Equipment Coating comprises a sophisticated blend of materials meticulously formulated to provide exceptional protection and durability to industrial machinery. At its core are polymer resins, engineered to imbue the coating with robustness, resilience, and adhesive properties. These resins form the backbone of the coating, ensuring it adheres firmly to the surface of the machinery, resisting peeling, chipping, or delamination over time.

-

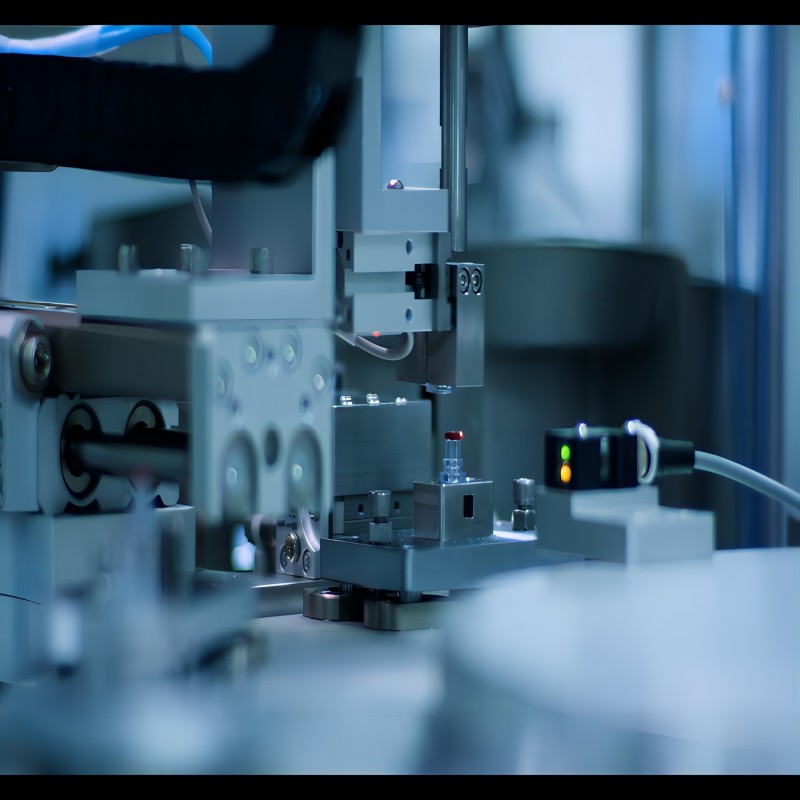

Assembly

The assembly of Intelligent Manufacturing Production Equipment at Demax is a meticulously coordinated process that ensures precision, efficiency, and reliability. It begins with the fabrication of individual components, including robotic arms, conveyor systems, CNC machines, 3D printers, smart sensors, and IoT devices, each manufactured to the highest standards of quality and precision. Once the components are ready, our skilled technicians meticulously assemble them according to the detailed design specifications. Every step of the assembly process is carefully monitored to ensure proper alignment, integration, and functionality of each component.