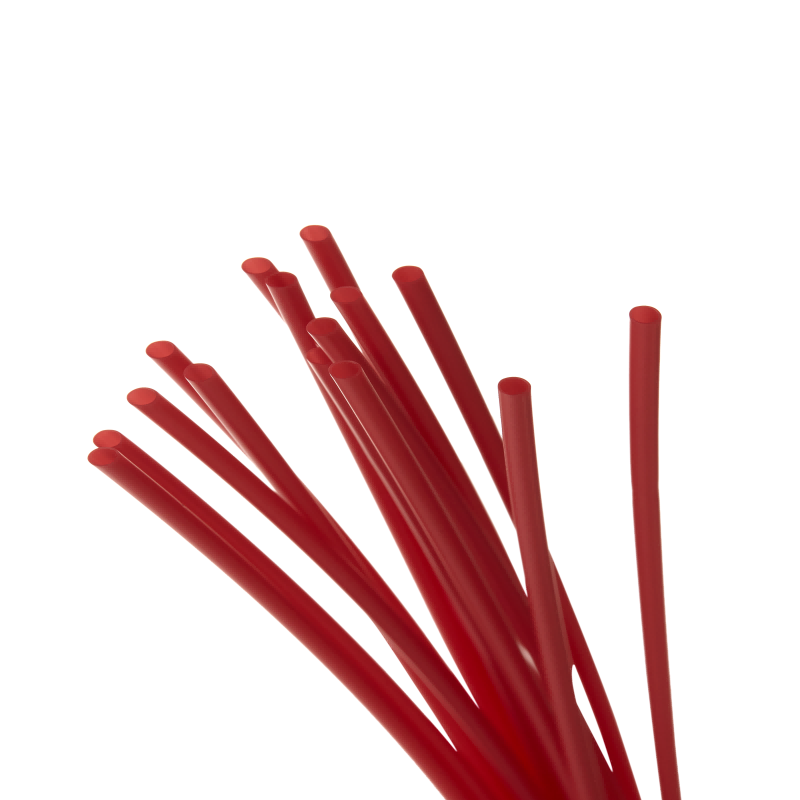

PE Tube

The PE Tube is meticulously crafted from high-quality polyethylene, a thermoplastic polymer renowned for its exceptional chemical resistance, flexibility, and biocompatibility.

The PE Tube, or Polyethylene Tube, represents a vital component in the realm of medical devices, serving as a conduit for the passage of fluids or gases within the body during various clinical procedures. Crafted from polyethylene, a resilient and biocompatible material, the PE Tube is engineered to meet the rigorous demands of medical interventions while ensuring patient safety and procedural efficacy.

Features

- Excellent chemical resistance

- Easy to process and low cost.

- Highly weldable.

Applications

- Endoscopy:PE Tubes are utilized in endoscopic procedures

- Urology: Widely employed in urological procedures, PE Tubes enable catheterization, drainage, or irrigation of the urinary tract

- Respiratory Care: In respiratory care settings, PE Tubes serve as connectors or adapters in respiratory devices, facilitating oxygen delivery, ventilation, or airway management

- Laboratory Testing: PE Tubes find application in laboratory settings for the transfer or containment of fluids or specimens during testing or analysis

- Dental Procedures:In dental applications, PE Tubes are employed for suction, irrigation, or delivery of dental materials during dental procedures

Technical Parameters

- Outer diameter: 0.5~10.0mm, tolerance: ±0.02mm

- Wall thickness: 0.03mm, tolerance: ±0.02mm

Related products

-

PTFE Liner

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer that is used as a liner in catheters due to its unique properties. PTFE has a very low coefficient of friction and is a highly durable material with excellent tensile strength. Catheter liners made of PTFE can withstand the stresses of use in medical devices and resist breaking or tearing.

PTFE is used as a liner in catheters because it provides a smooth, low-friction surface that helps reduce the risk of infection and tissue damage. They are also biocompatible so that most people won’t experience an allergic reaction or any negative response.

-

Flaring

Precision Medical Tubing Services Flaring involves the precise modification of medical-grade tubing materials to create flares and expansions. The composition of the tubing used in this process varies depending on the specific requirements of the medical device and the application. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

-

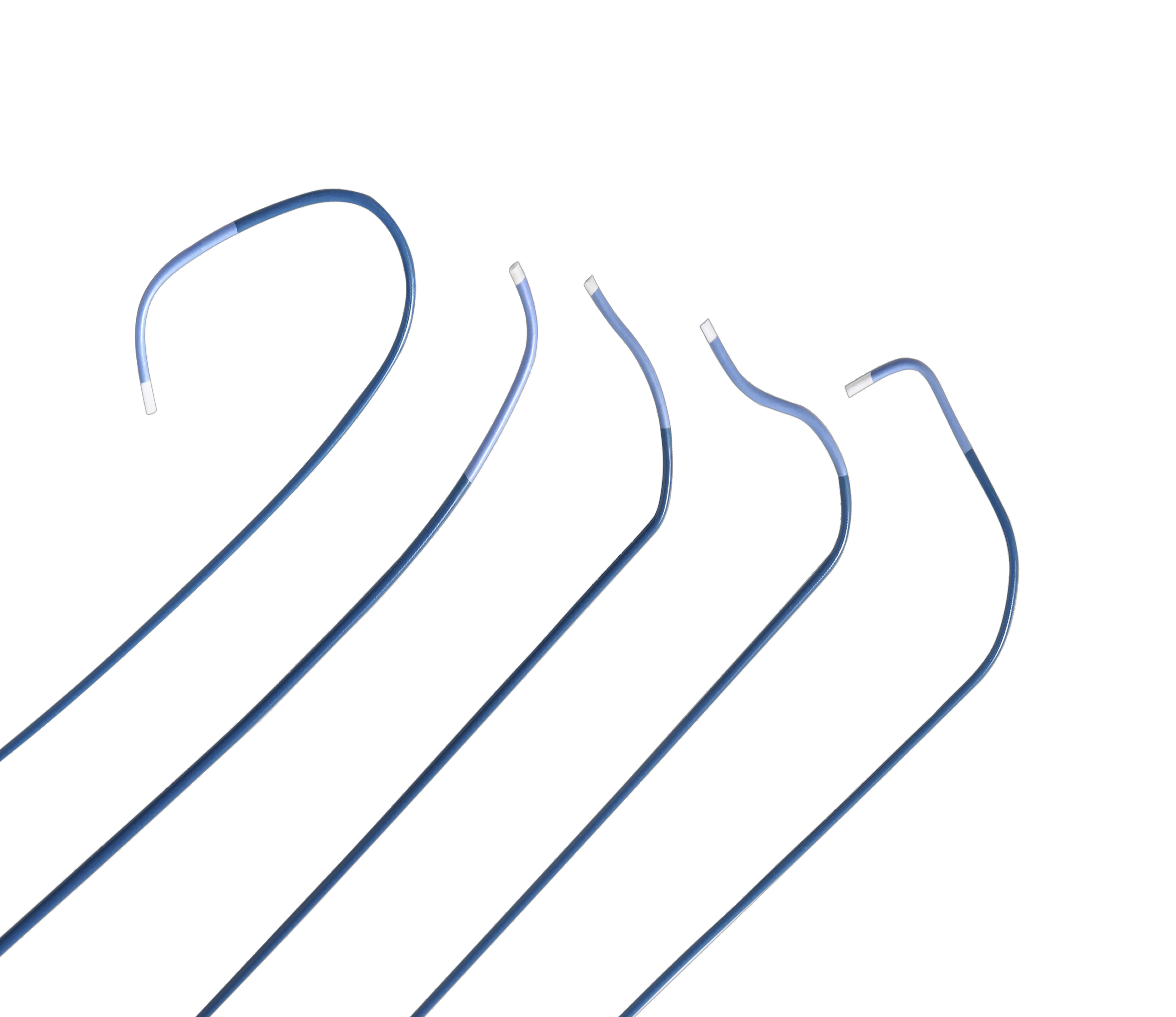

Angiography catheter

Features:

1. The tip is soft to reduce the risk of vascular injury;

2. PEBAX material, stronger configuration shape memory;

3. The port adopts a butterfly-wing ergonomic design, which is convenient to operate and more practical;

4. Good pushability and retractability, easy to control. -

TPU Tube

Demax TPU tubes are meticulously crafted from Thermoplastic Polyurethane (TPU), a premium synthetic polymer renowned for its exceptional elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This composition ensures the tubes’ longevity and reliability, even in the most demanding conditions. Demax’s commitment to quality extends to every aspect of their manufacturing process, from sourcing the finest materials to employing advanced production techniques. The result is a TPU tube that meets stringent industry standards, providing customers with confidence and peace of mind in their critical applications. Whether in medical procedures, laboratory experiments, or industrial processes, Demax TPU tubes deliver unmatched performance and durability, making them the preferred choice for professionals across various sectors.