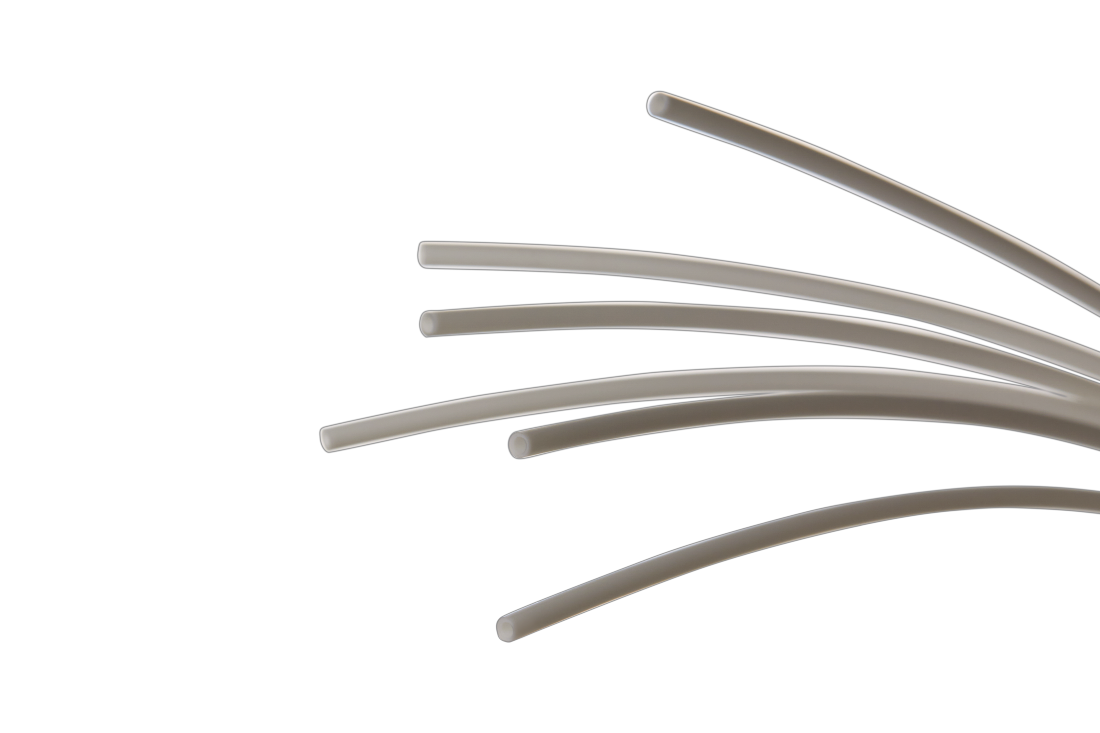

Pebax Tube

Pebax tubing is composed of a blend of thermoplastic elastomers, typically consisting of polyether and polyamide segments. This unique composition imparts Pebax tubing with its distinctive combination of flexibility, durability, and biocompatibility, making it an excellent choice for medical tubing applications.

Features

- Stable Product Size:The Balloon Material Tube maintains consistent dimensions, ensuring uniformity and reliability in the final balloon product.

- Coaxiality ≥ 95%: This specification denotes the concentricity or alignment of the layers within the tube, ensuring that the balloon material is evenly distributed around the central axis. High coaxiality enhances the performance and reliability of the balloon during inflation and deflation.

- Less Appearance Defects: The Balloon Material Tube exhibits minimal visual imperfections or defects such as air bubbles, wrinkles, or irregularities on the surface, ensuring aesthetic appeal and quality consistency in the final balloon product.

- Balloon Forming Pass Rate ≥ 90%: This specification indicates the success rate of the balloon forming process, where at least 90% of the balloon material tubes are successfully transformed into balloons without defects or failures. A high pass rate ensures manufacturing efficiency and reduces waste.

- The unique combination of flexibility, strength, and resistance to kinking, allowing for easy manipulation and insertion during medical procedures.

- Highly resistant to chemical degradation and offers low friction properties, reducing the risk of tissue irritation or damage during use.

Applications

Pebax Tubes find extensive use in various medical applications, including:- PTCA/PTA balloon tubing,

- PTA Balloon Catheter

- Angiography Catheter

- Guiding Catheter

- Microcatheter

- Other braided sheath tubing inner, outer, and outer sheath tubing

Technical Parameters

- Outer Diameter Specification(mm) : 0.5-10.0

- Outer Diameter Tolerance(mm): ±0125

- Minimum Tube Wall Thickness(mm): 0.03

- Tube Wall Thickness Tolerance(mm): ±02

Related products

-

Coating

Precision Medical Tubing Services Coating from Demax involves the application of specialized coatings onto medical-grade tubing substrates to enhance their performance and functionality. These coatings may include hydrophilic coatings, hydrophobic coatings, antimicrobial coatings, drug-eluting coatings, and more, depending on the specific requirements of the medical device and application. The coating materials are carefully selected for their biocompatibility, adhesion properties, and compatibility with the substrate material to ensure optimal performance and safety. Each coating is applied using precise coating techniques to achieve uniform coverage and consistent thickness, resulting in medical tubing with enhanced lubricity, biocompatibility, and other desirable properties.

-

Flaring

Precision Medical Tubing Services Flaring involves the precise modification of medical-grade tubing materials to create flares and expansions. The composition of the tubing used in this process varies depending on the specific requirements of the medical device and the application. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

-

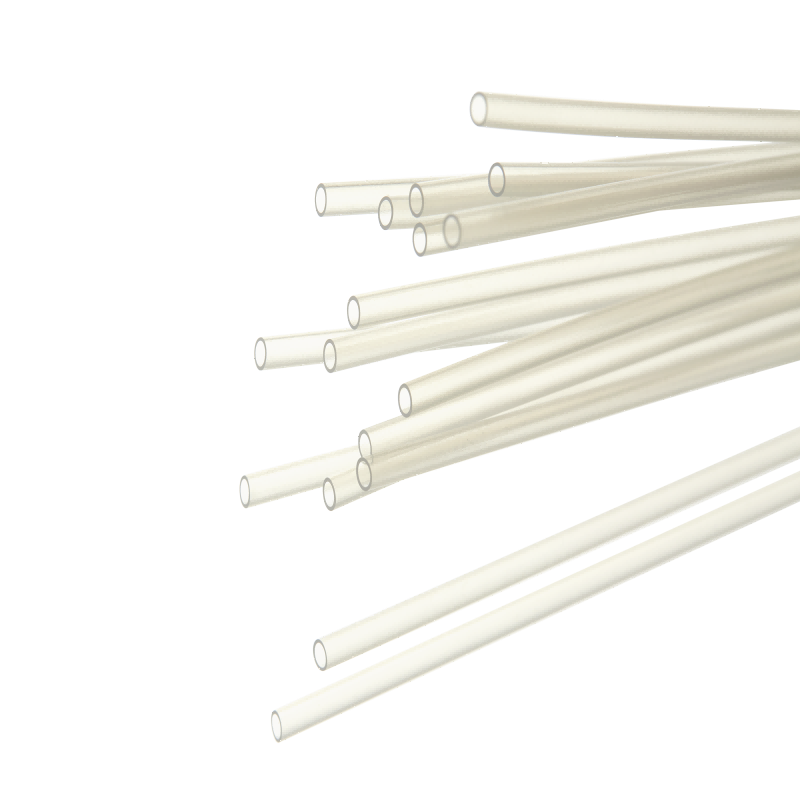

ETFE Tube

ETFE tubes manufactured by Demax are crafted from high-quality ethylene tetrafluoroethylene (ETFE) polymer.

This fluoropolymer material offers exceptional chemical resistance, mechanical strength, and biocompatibility, making it ideal for medical device applications.

ETFE tubes undergo precise extrusion processes to achieve consistent dimensions, smooth surfaces, and reliable performance in medical settings.

-

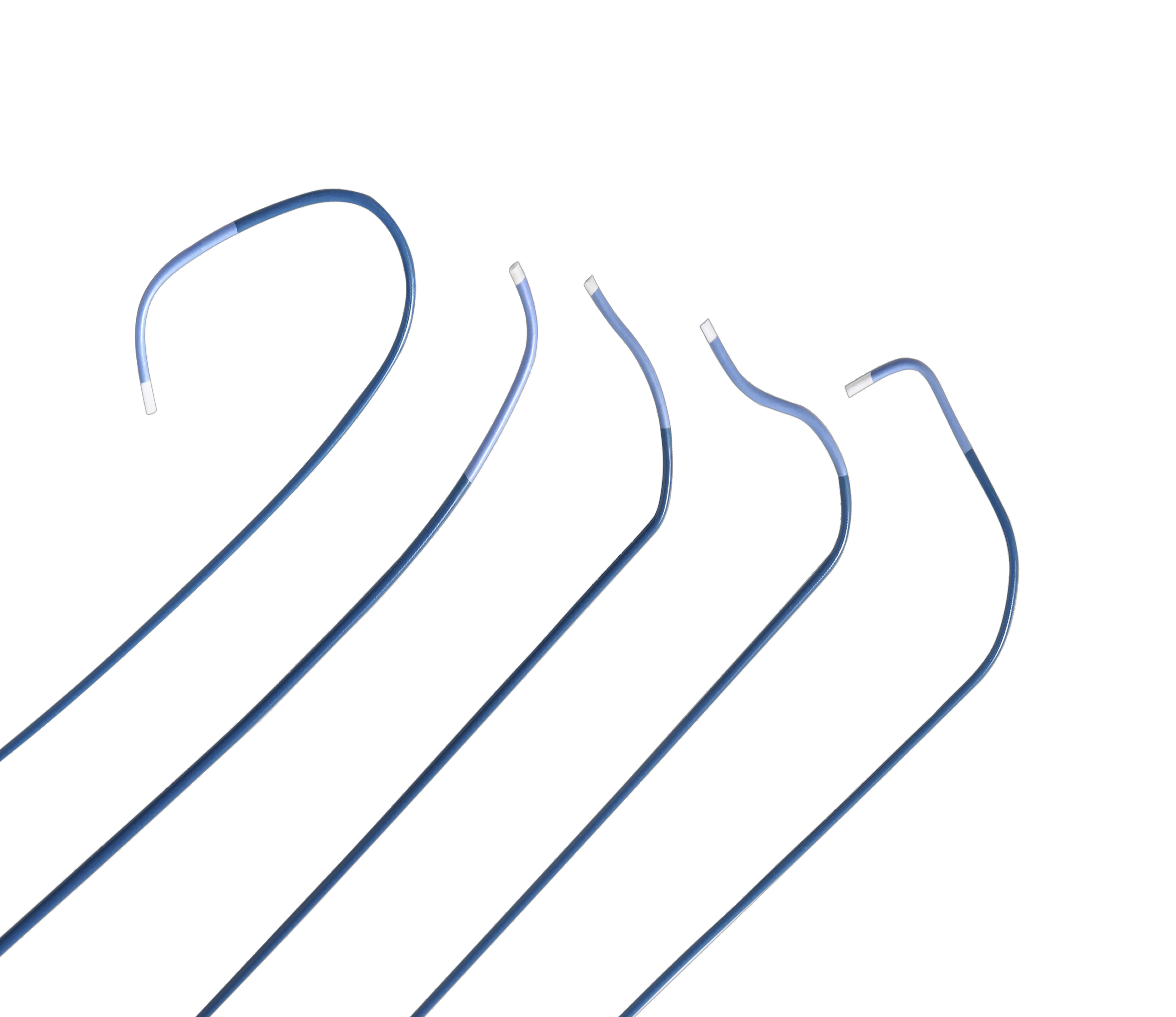

Angiography catheter

Features:

1. The tip is soft to reduce the risk of vascular injury;

2. PEBAX material, stronger configuration shape memory;

3. The port adopts a butterfly-wing ergonomic design, which is convenient to operate and more practical;

4. Good pushability and retractability, easy to control.