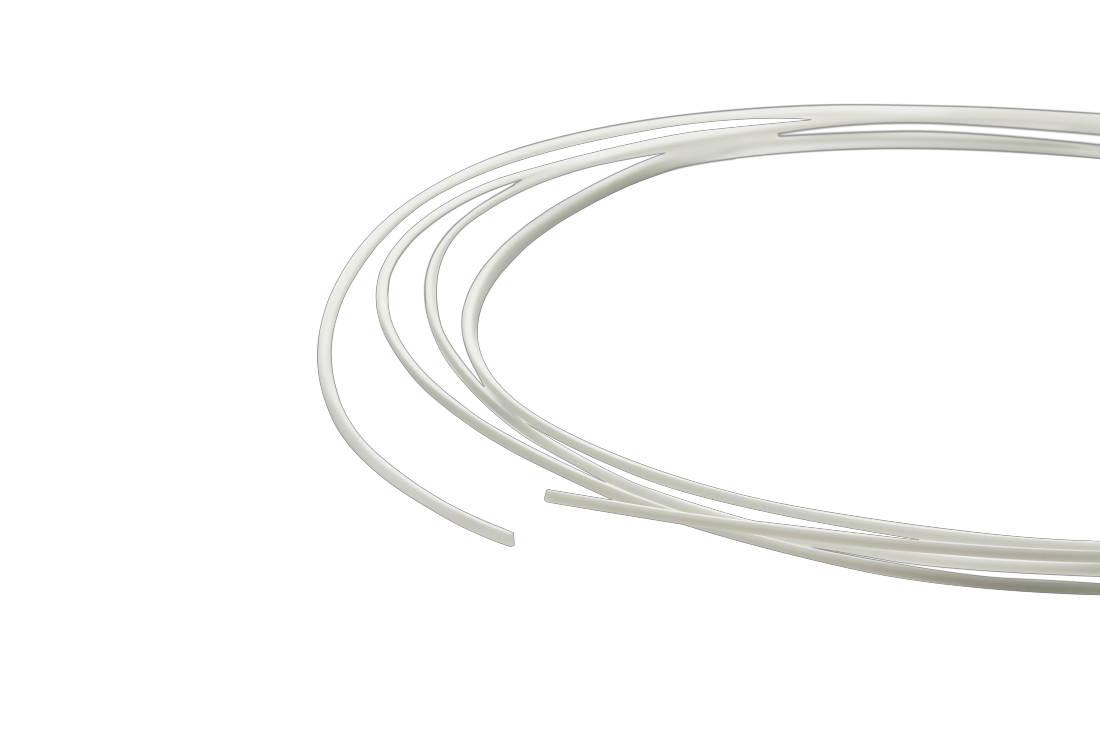

Peelable Tube

The Demax Peelable Tube is an innovative medical device designed to provide easy and controlled access to catheters and guidewires during medical procedures. Crafted with precision and utilizing advanced materials, this peelable tube offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

Features

- Peelable Design:Allows for easy and controlled access to catheters and guidewires.

- Medical-Grade Materials: Ensures biocompatibility and safety for patient use, minimizing the risk of adverse reactions or complications.

- Smooth Inner Surface:Allows for optimal fluid flow and reduces the risk of obstruction or blockage.

- Various Sizes and Lengths:Available in various sizes and lengths to accommodate different procedural requirements and patient anatomies.

Applications

- Peelable Sheath

- Introduce the tube (neuro intervention)

Technical Parameters

Specifications: 3F~12F Outer diameter (mm): 1.09~4.06 Outer diameter tolerance (mm): ±0.03 Inner diameter (mm): 0.99~3.96 Inner diameter tolerance (mm): ±0.03- Angiography: Used for the insertion and exchange of catheters and guidewires during diagnostic and interventional angiography procedures.

- Angioplasty: Employed for the insertion and exchange of balloon catheters and guidewires during percutaneous transluminal angioplasty (PTA) procedures.

- Stent Placement: Utilized for the insertion and exchange of stent delivery systems and guidewires during percutaneous stent placement procedures.

- Endovascular Therapy: Used for the insertion and exchange of various endovascular devices, including catheters, guidewires, and embolic agents, during endovascular therapy procedures.

- Vascular Access: Employed for the insertion and exchange of catheters and guidewires during vascular access procedures such as central venous catheterization and arterial catheterization.

Related products

-

PTFE Liner

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer that is used as a liner in catheters due to its unique properties. PTFE has a very low coefficient of friction and is a highly durable material with excellent tensile strength. Catheter liners made of PTFE can withstand the stresses of use in medical devices and resist breaking or tearing.

PTFE is used as a liner in catheters because it provides a smooth, low-friction surface that helps reduce the risk of infection and tissue damage. They are also biocompatible so that most people won’t experience an allergic reaction or any negative response.

-

Flaring

Precision Medical Tubing Services Flaring involves the precise modification of medical-grade tubing materials to create flares and expansions. The composition of the tubing used in this process varies depending on the specific requirements of the medical device and the application. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

-

Guiding Catheter

Guiding catheters are typically composed of biocompatible materials such as polyurethane or nylon, chosen for their flexibility, durability, and compatibility with bodily tissues. The catheter shaft is reinforced with braided or coiled wires to provide structural support and torqueability while maintaining flexibility for navigation through tortuous vascular anatomy. Soft, atraumatic tips minimize trauma to blood vessels during insertion and positioning. Radiopaque markers or bands incorporated into the catheter shaft enhance visibility under fluoroscopy or other imaging modalities, allowing for precise navigation and positioning during procedures. Demax’s guiding catheters are engineered with advanced materials and design features to optimize performance and safety, ensuring successful outcomes in a wide range of interventional procedures.

-

POM

In the context of medical devices, POM tubing is frequently employed as a core wire due to its exceptional properties. Characterized by its high hardness, POM tubing serves as a robust support structure within various medical instruments and devices. Its rigidity and durability make it well-suited for this role, providing stability and reinforcement to delicate components.

Moreover, POM tubing’s super smooth surface finish facilitates seamless movement within devices, ensuring smooth operation and minimal friction. This attribute is particularly advantageous in applications where precise control and maneuverability are essential, such as catheterization procedures or endoscopic interventions.