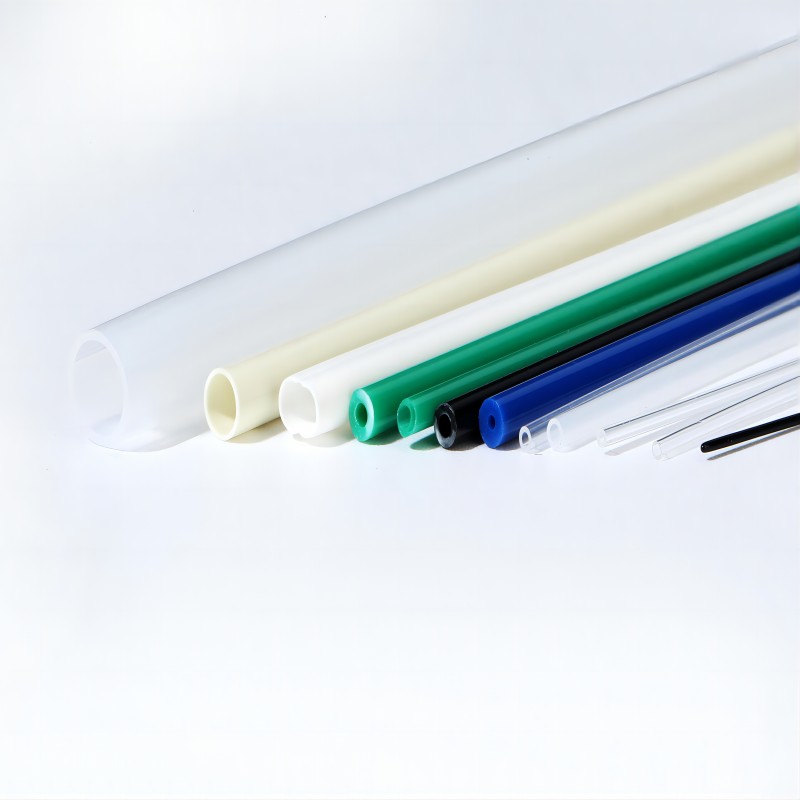

PP Tube

The PP Tube is meticulously crafted from high-quality polypropylene, a thermoplastic polymer renowned for its exceptional chemical resistance, durability, and biocompatibility. This composition ensures that the tube is safe for use within the body and can withstand the rigors of medical procedures without compromising patient safety or device performance. Employing state-of-the-art manufacturing techniques, Demax ensures uniformity in dimensions and performance, producing PP Tubes that meet the highest standards of quality and reliability. With Demax’s PP Tubes, healthcare professionals can perform medical procedures with confidence, knowing that they have a dependable and effective tool at their disposal to deliver optimal patient care.

- Outer Diameter (OD): Ranges from 1.5 to 7.0 millimeters (mm), providing flexibility to accommodate different clinical requirements and procedural preferences.

- Inner Diameter (ID): Ranges from 0.5 to 6.0 millimeters (mm), allowing for the passage of fluids, gases, or other substances within the body during medical procedures.

- Tolerance: Precision manufacturing ensures a tolerance level of ±0.02mm, maintaining consistency and reliability in dimensions, crucial for ensuring accurate and effective medical interventions.

- Material: Crafted from high-quality polypropylene, a thermoplastic polymer known for its durability, chemical resistance, and biocompatibility, ensuring safe and effective usage within the body.

- Length: Available in various lengths to accommodate different procedural requirements and patient anatomies, typically ranging from a few centimeters to several meters.

| Outer Diameter | Tube Wall Thickness(mm) | ||

| Outer Diameter Specification(mm) | Outer Diameter Tolerance(mm) | Minimum Tube Wall Thickness(mm) | Tube Wall Thickness Tolerance(mm) |

| 0.5-10.0 | ±0.03 | 0.05 | ±0.03 |

- Endoscopy: PP Tubes play a pivotal role in endoscopic procedures, facilitating the delivery of irrigation fluids, suction, or contrast agents to the gastrointestinal tract, aiding in visualization and diagnosis of gastrointestinal conditions.

- Urology: Widely utilized in urological procedures, PP Tubes enable catheterization, drainage, or irrigation of the urinary tract, contributing to the management of various urological disorders and conditions.

- Respiratory Care: In respiratory care settings, PP Tubes function as connectors or adapters in respiratory devices, facilitating oxygen delivery, ventilation, or airway management, crucial for maintaining respiratory function and managing respiratory disorders.

- Laboratory Testing: PP Tubes find application in laboratory settings, facilitating the transfer or containment of fluids or specimens during testing or analysis, essential for conducting diagnostic tests and research studies.

- Dental Procedures: In dental applications, PP Tubes are employed for suction, irrigation, or delivery of dental materials during dental procedures, aiding in oral hygiene maintenance and treatment of dental conditions.

Related products

-

PI Tube

The Demax PI Tube is constructed using polyimide (PI), a high-performance polymer known for its excellent mechanical properties and chemical resistance. This tubing is manufactured to meet the stringent standards of the medical industry, ensuring biocompatibility and safety for patient use. It is free from latex, phthalates, and other harmful substances, minimizing the risk of adverse reactions or complications.

-

Peelable Tube

The Demax Peelable Tube is an innovative medical device designed to provide easy and controlled access to catheters and guidewires during medical procedures. Crafted with precision and utilizing advanced materials, this peelable tube offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

-

Guiding Catheter

Guiding catheters are typically composed of biocompatible materials such as polyurethane or nylon, chosen for their flexibility, durability, and compatibility with bodily tissues. The catheter shaft is reinforced with braided or coiled wires to provide structural support and torqueability while maintaining flexibility for navigation through tortuous vascular anatomy. Soft, atraumatic tips minimize trauma to blood vessels during insertion and positioning. Radiopaque markers or bands incorporated into the catheter shaft enhance visibility under fluoroscopy or other imaging modalities, allowing for precise navigation and positioning during procedures. Demax’s guiding catheters are engineered with advanced materials and design features to optimize performance and safety, ensuring successful outcomes in a wide range of interventional procedures.

-

FEP Heat Shrink Tube

The FEP Heat Shrink Tube boasts a composition rooted in fluorinated ethylene propylene (FEP), a thermoplastic polymer renowned for its exceptional properties in medical applications.

FEP exhibits a unique combination of characteristics that make it ideally suited for medical tubing. Its molecular structure imparts remarkable clarity to the tubing, allowing for optimal visualization of fluids and instruments during medical procedures, essential for accurate monitoring and precise manipulation.