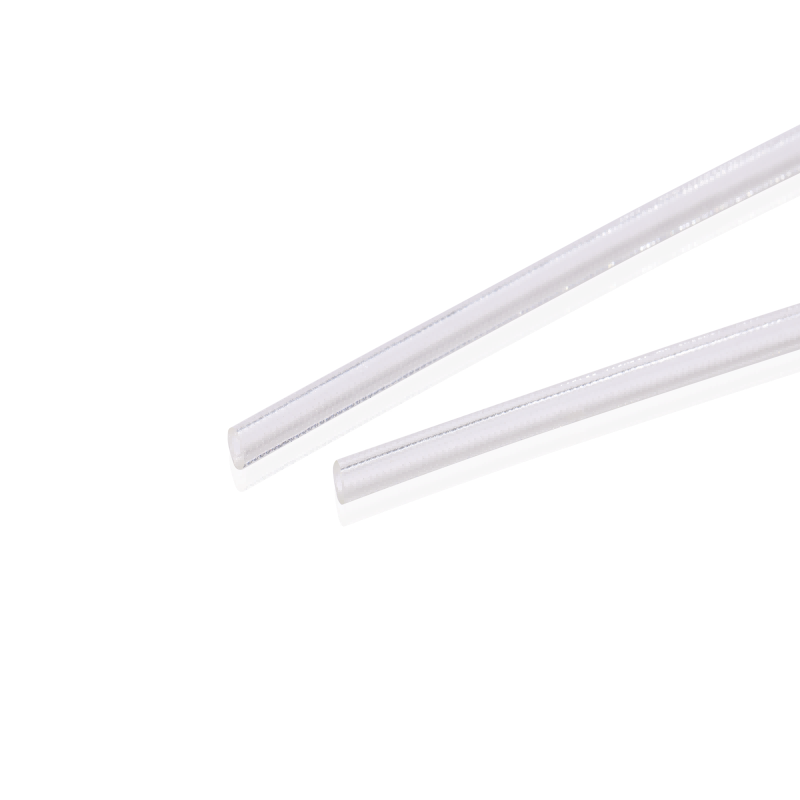

PU Braided Tube

The Demax PU Braided Tube is constructed using polyurethane (PU), a high-performance polymer known for its excellent mechanical properties and chemical resistance. This tubing is reinforced with a braided layer, providing enhanced strength and resistance to kinking and collapse. It is manufactured to meet the stringent standards of the medical industry, ensuring biocompatibility and safety for patient use. The tubing is free from latex, phthalates, and other harmful substances, minimizing the risk of adverse reactions or complications.

| Outer Diameter | Tube Wall Thickness(mm) | ||

| Outer Diameter(mm) | Outer Diameter Tolerance(mm) | Inner Diameter(mm) | Inner Diameter Tolerance(mm) |

| 0.144” | ±0.002” | 0.071” | ±0.002” |

-

High Flexibility: The PU braided tubing offers high flexibility, allowing for easy manipulation and positioning during medical procedures. It can be bent or twisted without kinking, ensuring smooth fluid flow and optimal performance.

- Braided Reinforcement: The tubing is reinforced with a braided layer, providing enhanced strength and resistance to kinking and collapse. This reinforcement allows the tubing to maintain its shape and structural integrity even under high-pressure conditions.

- Excellent Durability: Engineered to withstand the rigors of medical procedures, the PU braided tubing exhibits excellent durability and resistance to deformation. It maintains its structural integrity even under high-pressure conditions, ensuring reliable performance throughout the procedure.

- Chemical Resistance: The tubing is highly resistant to chemicals and solvents commonly used in medical settings, ensuring compatibility with various fluids and medications. This resistance minimizes the risk of degradation or contamination, preserving the purity of the transported fluids.

- Smooth Inner Surface: The tubing features a smooth inner surface, allowing for optimal fluid flow and reducing the risk of obstruction or blockage. This smooth surface minimizes friction and turbulence, ensuring efficient fluid delivery during medical procedures.

The Demax PU Braided Tube finds applications in a wide range of medical procedures, including:

- Intravenous Therapy: Used for the delivery of fluids, medications, and blood products during intravenous (IV) therapy procedures.

- Enteral Feeding: Employed for the delivery of enteral nutrition solutions and medications during enteral feeding procedures.

- Endoscopy: Utilized as part of endoscopic systems for irrigation, suction, and insufflation during gastrointestinal procedures such as gastroscopy and colonoscopy.

- Respiratory Therapy: Used for the delivery of oxygen and other respiratory gases during respiratory therapy procedures, including mechanical ventilation and oxygen therapy.

- Urology Procedures: Employed for the delivery of irrigation fluids and contrast media during urological procedures such as cystoscopy and ureteroscopy.

Related products

-

PTFE Liner

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer that is used as a liner in catheters due to its unique properties. PTFE has a very low coefficient of friction and is a highly durable material with excellent tensile strength. Catheter liners made of PTFE can withstand the stresses of use in medical devices and resist breaking or tearing.

PTFE is used as a liner in catheters because it provides a smooth, low-friction surface that helps reduce the risk of infection and tissue damage. They are also biocompatible so that most people won’t experience an allergic reaction or any negative response.

-

Coating

Precision Medical Tubing Services Coating from Demax involves the application of specialized coatings onto medical-grade tubing substrates to enhance their performance and functionality. These coatings may include hydrophilic coatings, hydrophobic coatings, antimicrobial coatings, drug-eluting coatings, and more, depending on the specific requirements of the medical device and application. The coating materials are carefully selected for their biocompatibility, adhesion properties, and compatibility with the substrate material to ensure optimal performance and safety. Each coating is applied using precise coating techniques to achieve uniform coverage and consistent thickness, resulting in medical tubing with enhanced lubricity, biocompatibility, and other desirable properties.

-

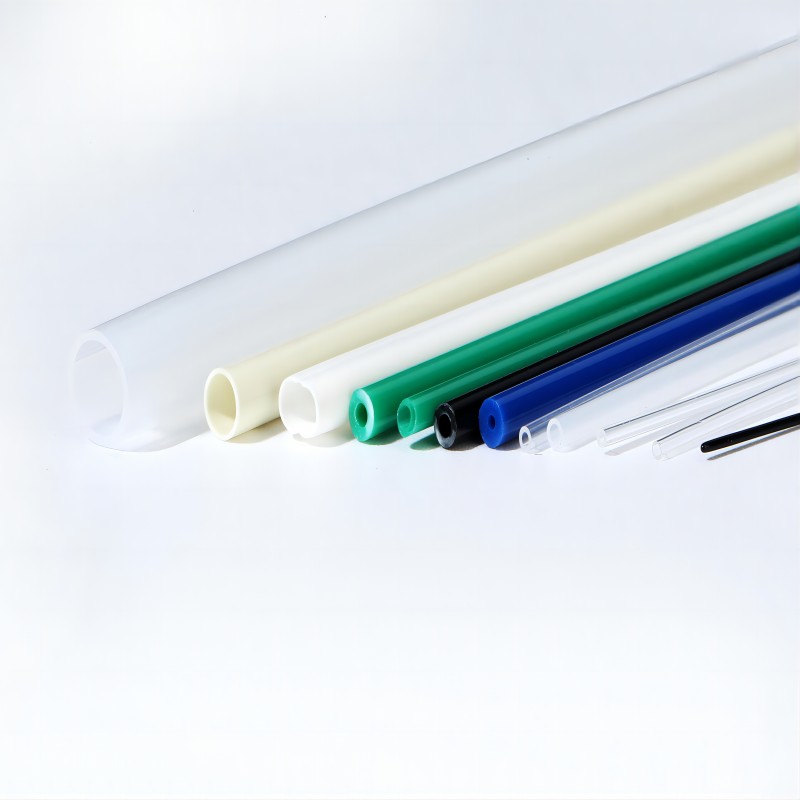

PP Tube

The PP Tube is meticulously crafted from high-quality polypropylene, a thermoplastic polymer renowned for its exceptional chemical resistance, durability, and biocompatibility. This composition ensures that the tube is safe for use within the body and can withstand the rigors of medical procedures without compromising patient safety or device performance. Employing state-of-the-art manufacturing techniques, Demax ensures uniformity in dimensions and performance, producing PP Tubes that meet the highest standards of quality and reliability. With Demax’s PP Tubes, healthcare professionals can perform medical procedures with confidence, knowing that they have a dependable and effective tool at their disposal to deliver optimal patient care.

-

Guiding Catheter

Guiding catheters are typically composed of biocompatible materials such as polyurethane or nylon, chosen for their flexibility, durability, and compatibility with bodily tissues. The catheter shaft is reinforced with braided or coiled wires to provide structural support and torqueability while maintaining flexibility for navigation through tortuous vascular anatomy. Soft, atraumatic tips minimize trauma to blood vessels during insertion and positioning. Radiopaque markers or bands incorporated into the catheter shaft enhance visibility under fluoroscopy or other imaging modalities, allowing for precise navigation and positioning during procedures. Demax’s guiding catheters are engineered with advanced materials and design features to optimize performance and safety, ensuring successful outcomes in a wide range of interventional procedures.