Punching

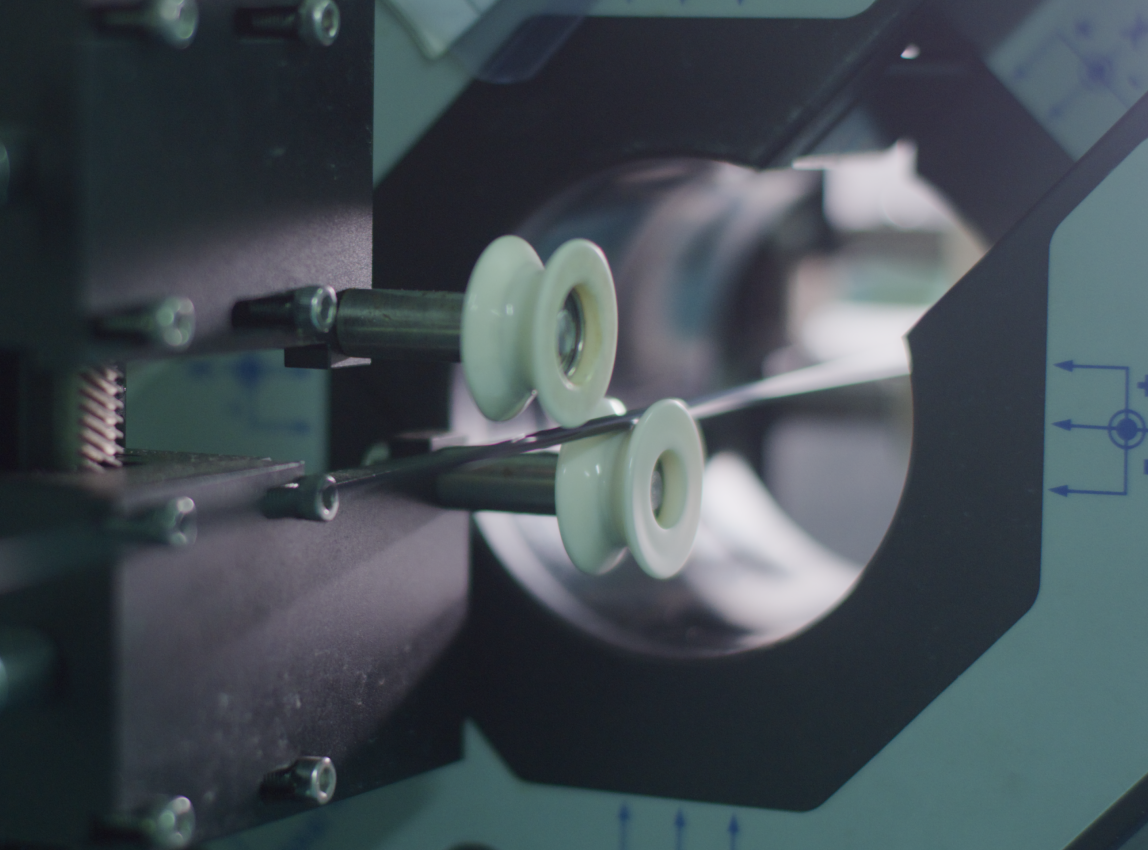

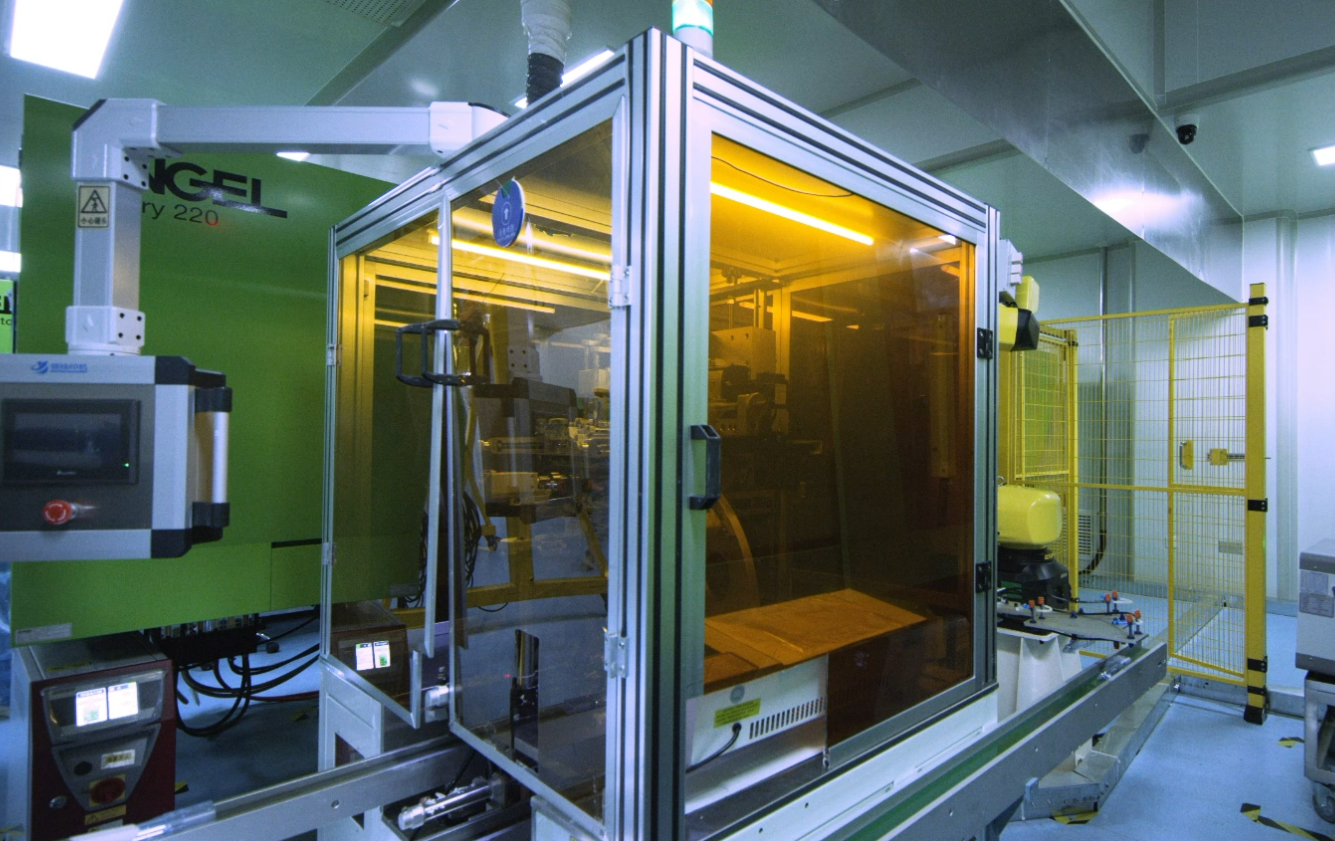

Precision Medical Tubing Services Punching from Demax involves the precise creation of perforations, holes, or patterns in medical-grade tubing using advanced punching methods and equipment. The tubing material, typically made from medical-grade polymers such as polyethylene (PE), polyurethane (PU), or silicone, is carefully selected for its biocompatibility, flexibility, and durability. During the punching process, specialized punches and dies are used to create holes of specific sizes, shapes, and configurations in the tubing, allowing for precise control over the perforation characteristics. Each punched hole is inspected and verified to ensure that it meets the required tolerances and quality standards. Demax’s expertise in precision punching ensures that punched medical tubing maintains its structural integrity, biocompatibility, and performance, meeting the demanding requirements of medical device manufacturers and healthcare professionals.

- Punching Methods: Demax offers a variety of punching methods to accommodate different tubing materials and designs, including mechanical punching, laser punching, and ultrasonic punching. Each method is selected based on the specific requirements of the application to achieve the desired hole size, shape, and accuracy.

- Hole Size and Configuration: Our precision punching services can create holes of various sizes, shapes, and configurations in medical tubing, ranging from micro-perforations to larger holes. Whether round, oval, rectangular, or custom-shaped, Demax can punch precise holes to meet the specific needs of medical device manufacturers.

- Tubing Compatibility: Our punching services are compatible with a wide range of medical-grade tubing materials, including polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, and more. We ensure that the punching process does not compromise the integrity or properties of the tubing material, maintaining biocompatibility and performance.

- Tolerance and Accuracy: Demax maintains tight tolerances and high levels of accuracy in the punching process, ensuring that the location, size, and spacing of holes are consistent and precise. Our advanced punching equipment and quality control measures guarantee uniformity and reliability in punched medical tubing.

- Scalability: Whether producing small prototype batches or large-volume production runs, Demax’s precision punching services are scalable to accommodate varying project sizes and timelines. We have the capacity and capabilities to fulfill the needs of medical device manufacturers with efficiency and flexibility

- Perforated Drainage Tubing: Punched medical tubing is commonly used in drainage systems and catheters to facilitate fluid drainage from body cavities or wounds, improving patient comfort and clinical outcomes.

- Fluid Delivery Systems: Perforated medical tubing is utilized in fluid delivery systems, such as IV infusion sets and enteral feeding tubes, to control the flow rate of fluids and medications, ensuring accurate delivery and dosage.

- Tissue and Suture Management: Punched medical tubing is employed in tissue approximation and suture management devices to facilitate wound closure and healing, providing surgeons with precise control and maneuverability during procedures.

- Diagnostic and Therapeutic Devices: Perforated medical tubing serves as a component in various diagnostic and therapeutic devices, including endoscopic instruments, biopsy forceps, and surgical staplers, enhancing functionality and performance.

Related products

-

Flaring

Precision Medical Tubing Services Flaring involves the precise modification of medical-grade tubing materials to create flares and expansions. The composition of the tubing used in this process varies depending on the specific requirements of the medical device and the application. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

-

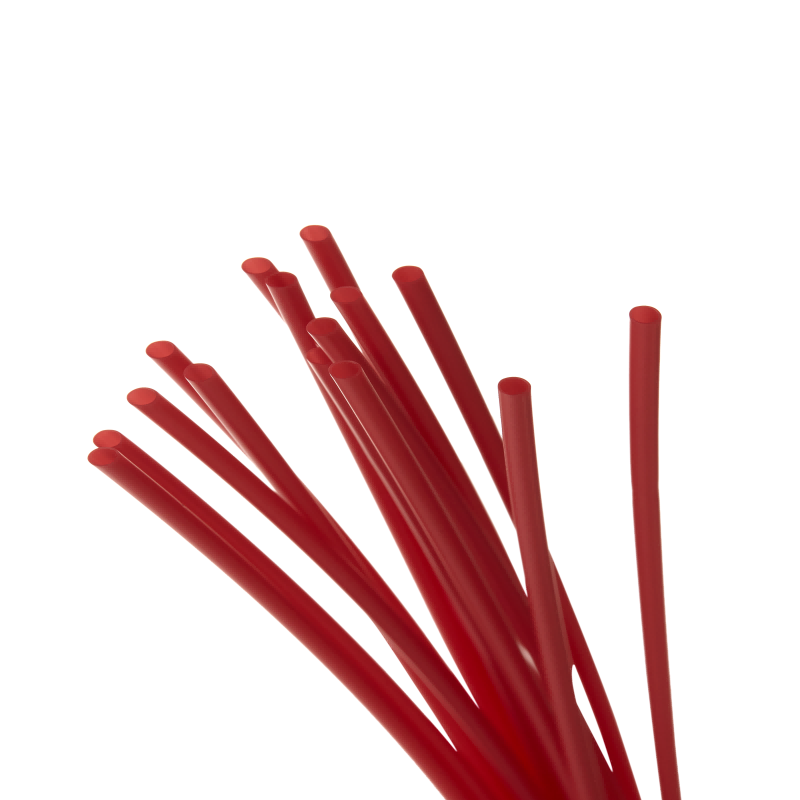

PE Tube

The PE Tube is meticulously crafted from high-quality polyethylene, a thermoplastic polymer renowned for its exceptional chemical resistance, flexibility, and biocompatibility.

The PE Tube, or Polyethylene Tube, represents a vital component in the realm of medical devices, serving as a conduit for the passage of fluids or gases within the body during various clinical procedures. Crafted from polyethylene, a resilient and biocompatible material, the PE Tube is engineered to meet the rigorous demands of medical interventions while ensuring patient safety and procedural efficacy.

-

Microcatheter

Features:

1. PTFE inner layer allows for smooth passage for embolic agents;

2. Optimal trackability through tortuous anatomy;

3. Available in pre-shaped tip shape configurations for vessel engagement;

4. Four shapes provides more option for clinical usage;

5. 2.0F/2.2F/2.6F/2.8F models are available;

6. Hydrophilic coating technology, smoothly through the lesion. -

TPU Tube

Demax TPU tubes are meticulously crafted from Thermoplastic Polyurethane (TPU), a premium synthetic polymer renowned for its exceptional elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This composition ensures the tubes’ longevity and reliability, even in the most demanding conditions. Demax’s commitment to quality extends to every aspect of their manufacturing process, from sourcing the finest materials to employing advanced production techniques. The result is a TPU tube that meets stringent industry standards, providing customers with confidence and peace of mind in their critical applications. Whether in medical procedures, laboratory experiments, or industrial processes, Demax TPU tubes deliver unmatched performance and durability, making them the preferred choice for professionals across various sectors.