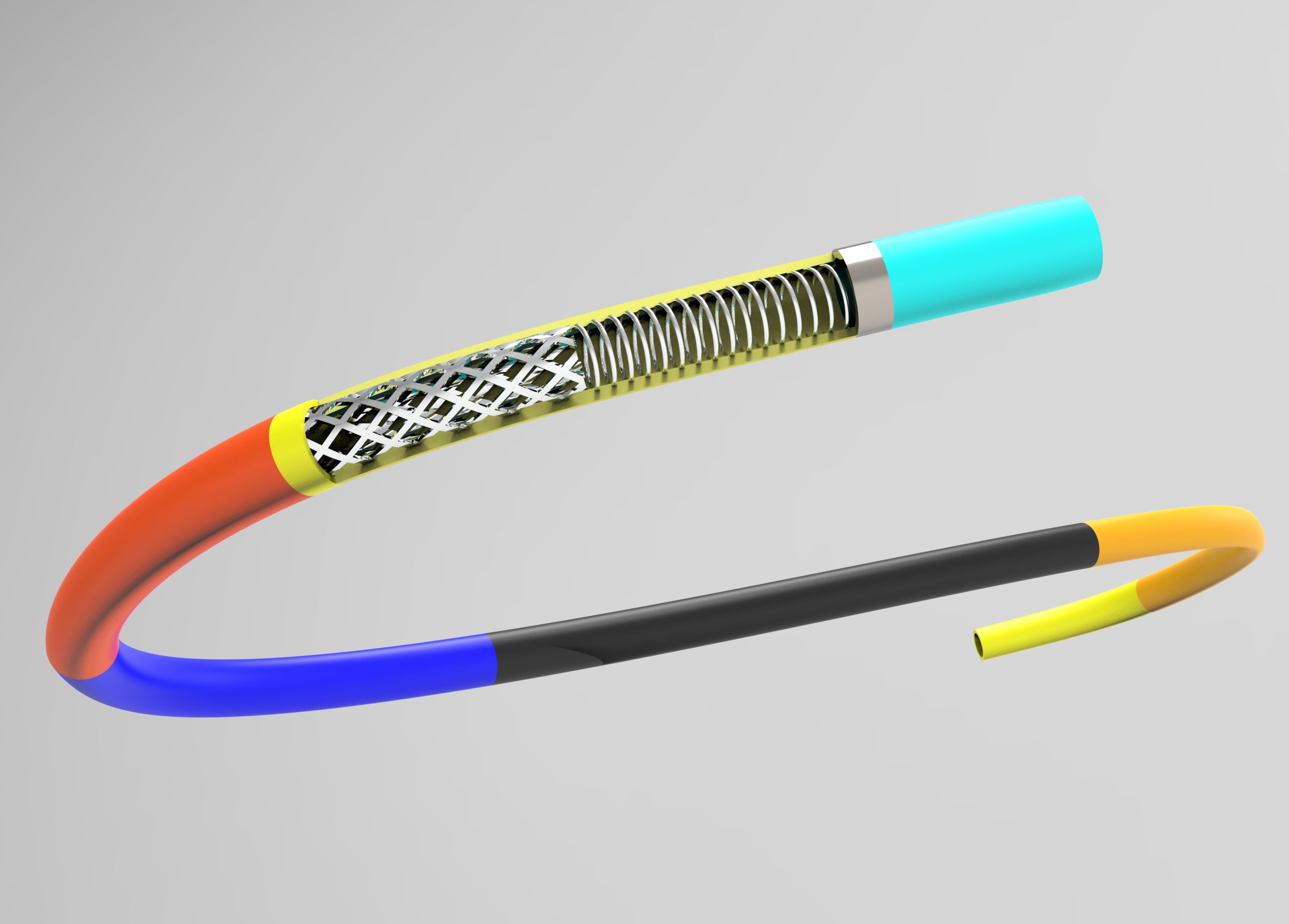

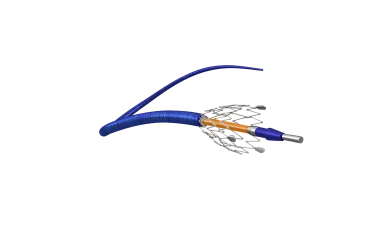

Stent delivery system Braided catheter

Establishing an access channel forinstruments to enter the body

Customizable in various sizes to meet different lesion requirements

Features

PTFE smooth inner wall- Reduces resistance, during device delivery

- Provides high-strength support,smoothly delivering stents, occluders,and other implantable devices

- Excellent kink resistance performance,flexibly adapting tovarious curved blood vessels

- Smooth pushing, reduce friction,improve passability

- Simultaneously,effectively reduces damage to the human body

- Clear positioning,ensuring precise stent release

Additional clinical applications of braided catheters:

- Cardiovascular & Structural heart:Aortic, mitral, tricuspid valve replacement delivery systems, Heart muscle cell therapy delivery system.

- Gastroenterology:Endoscopic suturing system, Laparoscopic mixing device for surgical sealant, Stomach wireless implant delivery system to prevent heart failure, lmplant delivery system for acid reflux disease.

- Neurology:Neurovascular guiding catheter, Clot Retriever device for acute ischemic stroke

- Gynecology:Fertilization delivery system, lntroducer of vaginal mesh implant, Ureteral stent delivery

- Pulmonary:Delivery system for artificial larynx, ENT navigation system.

Technical Parameters

- Catheter outer diameter: 5-28F

- Inner and outerdiameter tolerance: ±02-0.05mm

- Catheter length:500-2600mm

- Catheter tensilestrength: 30-300N

- Minimum catheter bending radius:10mm

- Catheter elongationrate: 0-5%, customizable (10N constant tension applied to both ends of the tubing)

- Catheter surface treatment: Hydrophilic coating

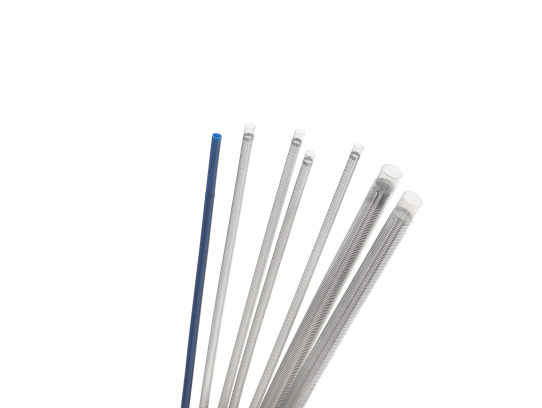

- Catheter reinforcement structure:Steel wire mesh, nylon wire mesh

- Catheter materials:PTFE, Pebax, PE, Nylon, PU, SUS

- Catheter radiopaque materials:Platinum-iridium alloy marker, tantalum marker, barium sulfate, tungsten, bismuth oxide

- Catheter layers: 3 layers, 4 layers, 5 layers

- Catheter hardness:TPU, PEBAX (25D – 72D)

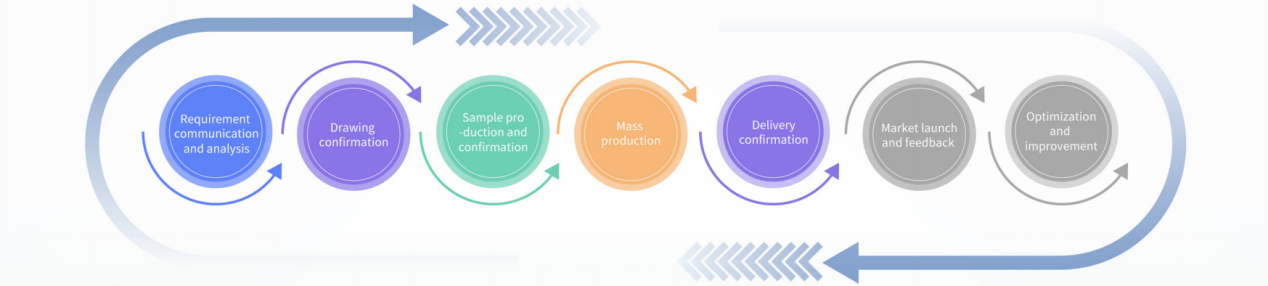

Our Collaborative Approach

Related products

-

Peelable Tube

The Demax Peelable Tube is an innovative medical device designed to provide easy and controlled access to catheters and guidewires during medical procedures. Crafted with precision and utilizing advanced materials, this peelable tube offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

-

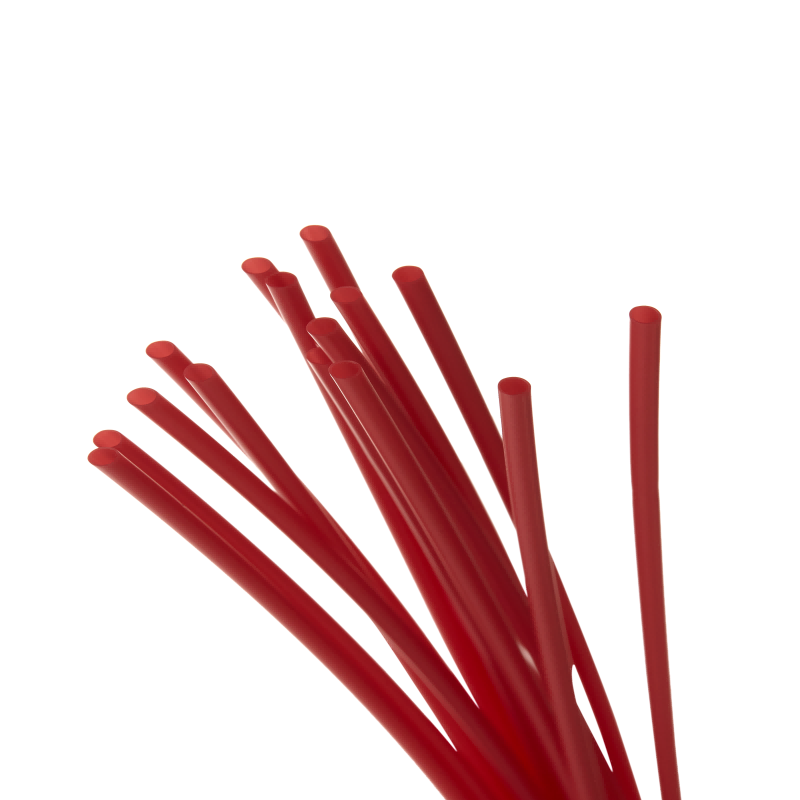

PE Tube

The PE Tube is meticulously crafted from high-quality polyethylene, a thermoplastic polymer renowned for its exceptional chemical resistance, flexibility, and biocompatibility.

The PE Tube, or Polyethylene Tube, represents a vital component in the realm of medical devices, serving as a conduit for the passage of fluids or gases within the body during various clinical procedures. Crafted from polyethylene, a resilient and biocompatible material, the PE Tube is engineered to meet the rigorous demands of medical interventions while ensuring patient safety and procedural efficacy.

-

PP Tube

The PP Tube is meticulously crafted from high-quality polypropylene, a thermoplastic polymer renowned for its exceptional chemical resistance, durability, and biocompatibility. This composition ensures that the tube is safe for use within the body and can withstand the rigors of medical procedures without compromising patient safety or device performance. Employing state-of-the-art manufacturing techniques, Demax ensures uniformity in dimensions and performance, producing PP Tubes that meet the highest standards of quality and reliability. With Demax’s PP Tubes, healthcare professionals can perform medical procedures with confidence, knowing that they have a dependable and effective tool at their disposal to deliver optimal patient care.

-

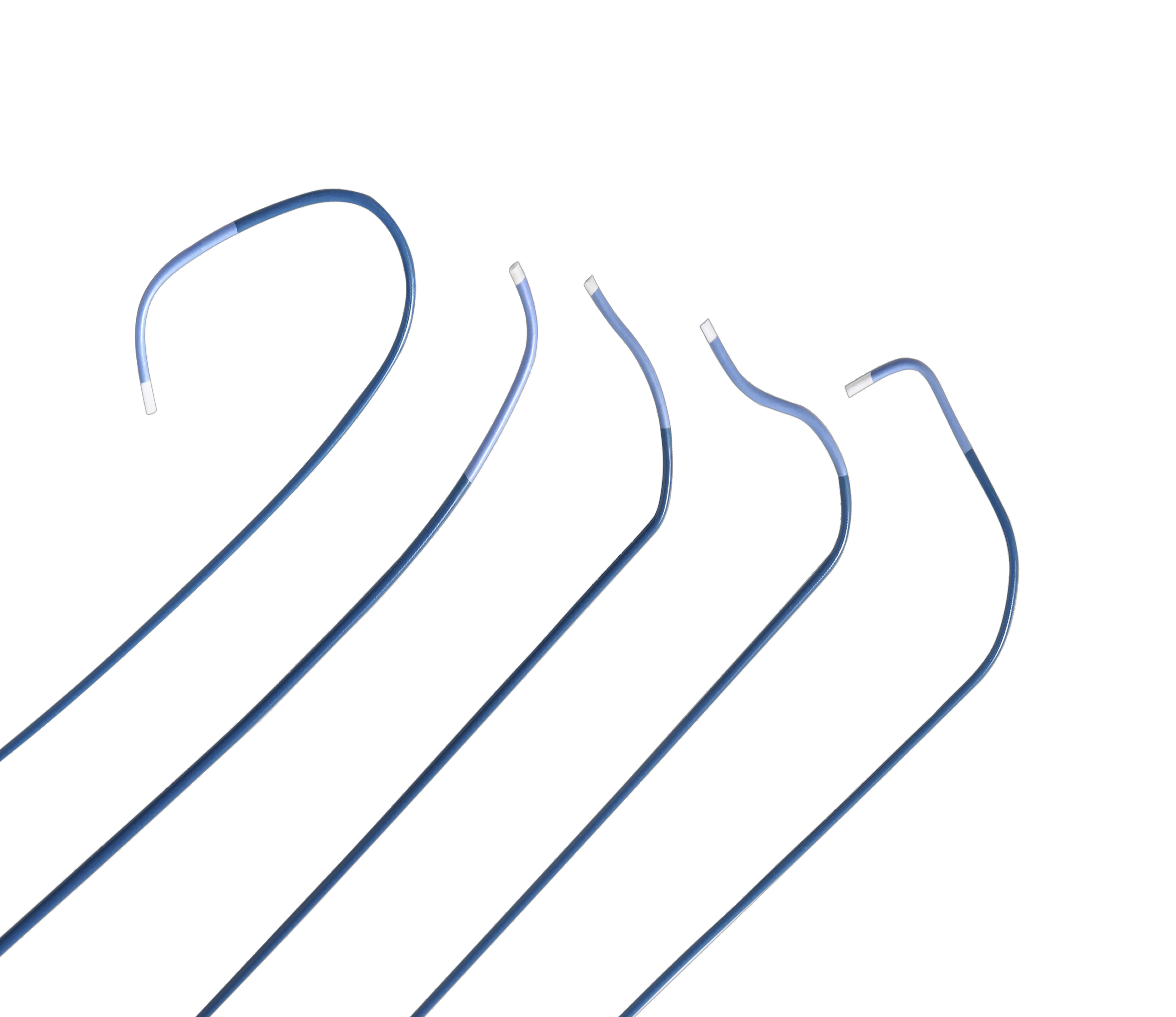

Angiography catheter

Features:

1. The tip is soft to reduce the risk of vascular injury;

2. PEBAX material, stronger configuration shape memory;

3. The port adopts a butterfly-wing ergonomic design, which is convenient to operate and more practical;

4. Good pushability and retractability, easy to control.