Testing

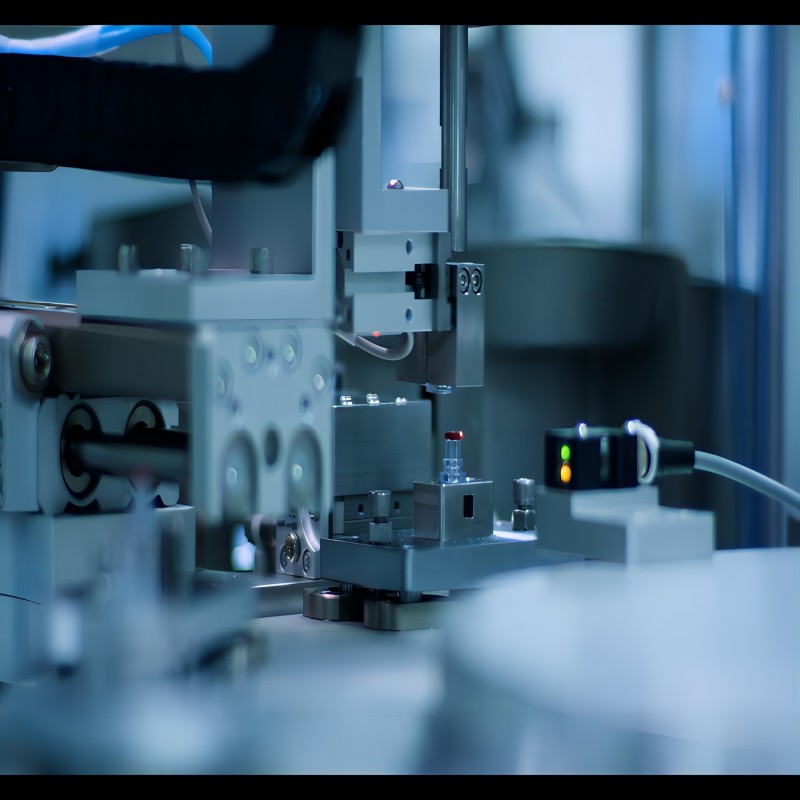

Demax’s Intelligent Manufacturing Production Equipment Testing service combines advanced testing methodologies, state-of-the-art equipment, and experienced professionals to ensure the reliability and performance of automated manufacturing systems. The composition of this service includes a variety of testing protocols tailored to specific requirements, advanced testing equipment such as specialized rigs and data acquisition systems, and a team of skilled testing engineers with expertise in industrial automation and quality assurance.

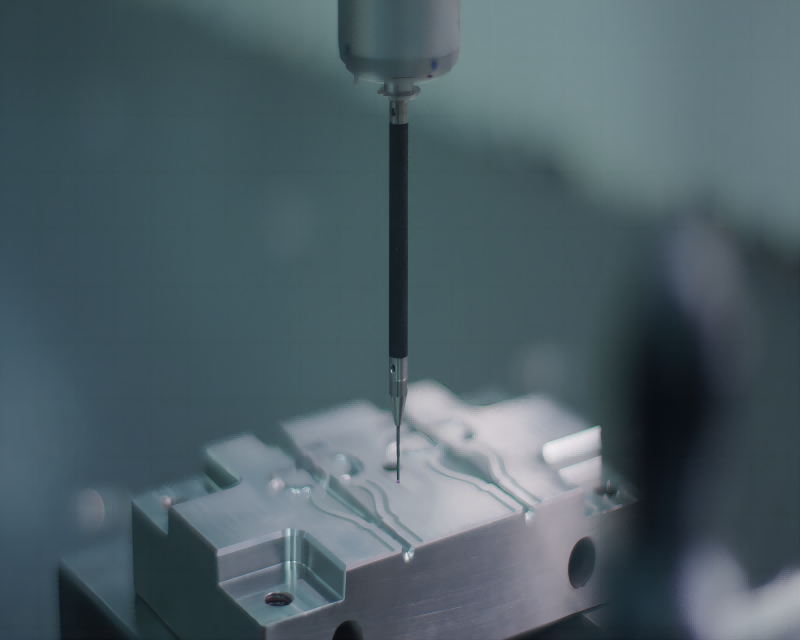

- Air Tightness Testing Equipment for Balloon In-deflation Device: This equipment ensures the airtight seal of Balloon In-deflation Devices used in medical procedures. Simultaneously testing six products, it efficiently verifies sealing integrity, crucial for patient safety. An automatic warning system alerts operators to abnormalities, ensuring prompt intervention.

- Fatigue Testing Machine: Utilized across industries, this machine assesses product durability under repetitive stress. In automotive and aerospace, it tests component fatigue to ensure safe, reliable operation. Insights gained aid in design optimization and materials selection for enhanced product reliability.

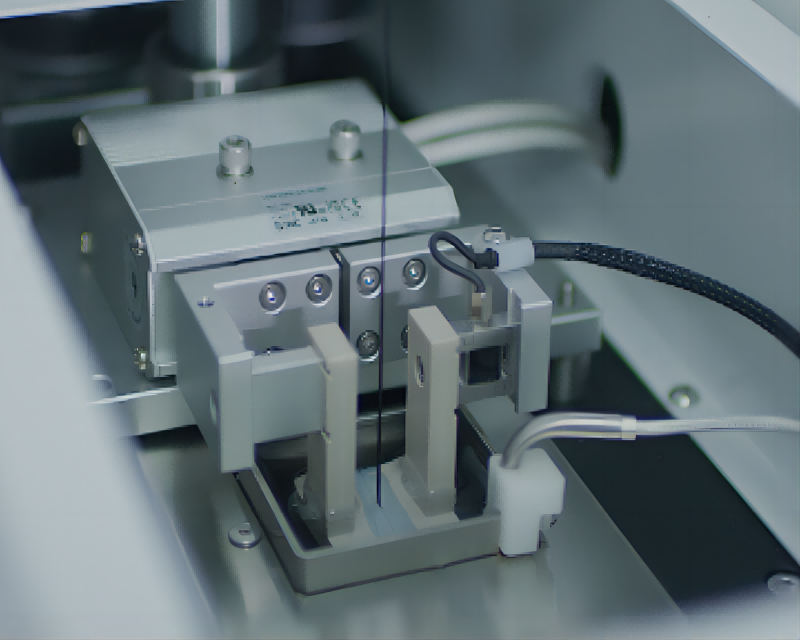

- Torsion Testing Machine for Luer: Critical for medical devices, it evaluates the mechanical strength of Luer connectors. Testing torsional stress ensures connectors can withstand clinical use, preventing risks associated with failure.

- Water Pressing Injection Testing Machine: Employed in construction, automotive, and electronics, it tests product waterproofing. High-pressure liquid injection replicates real-world conditions, ensuring product integrity and preventing water damage.

Related products

-

Coating

Intelligent Manufacturing Production Equipment Coating comprises a sophisticated blend of materials meticulously formulated to provide exceptional protection and durability to industrial machinery. At its core are polymer resins, engineered to imbue the coating with robustness, resilience, and adhesive properties. These resins form the backbone of the coating, ensuring it adheres firmly to the surface of the machinery, resisting peeling, chipping, or delamination over time.

-

Assembly

The assembly of Intelligent Manufacturing Production Equipment at Demax is a meticulously coordinated process that ensures precision, efficiency, and reliability. It begins with the fabrication of individual components, including robotic arms, conveyor systems, CNC machines, 3D printers, smart sensors, and IoT devices, each manufactured to the highest standards of quality and precision. Once the components are ready, our skilled technicians meticulously assemble them according to the detailed design specifications. Every step of the assembly process is carefully monitored to ensure proper alignment, integration, and functionality of each component.

-

Design

The composition of Intelligent Manufacturing Production Equipment designs by Demax is a meticulously orchestrated integration of cutting-edge technologies and specialized components. These designs typically include a combination of robotic arms, automated conveyor systems, CNC machines, 3D printers, smart sensors, and IoT devices. Each component is carefully selected and configured to optimize manufacturing processes, enhance productivity, and ensure the highest standards of quality and performance.