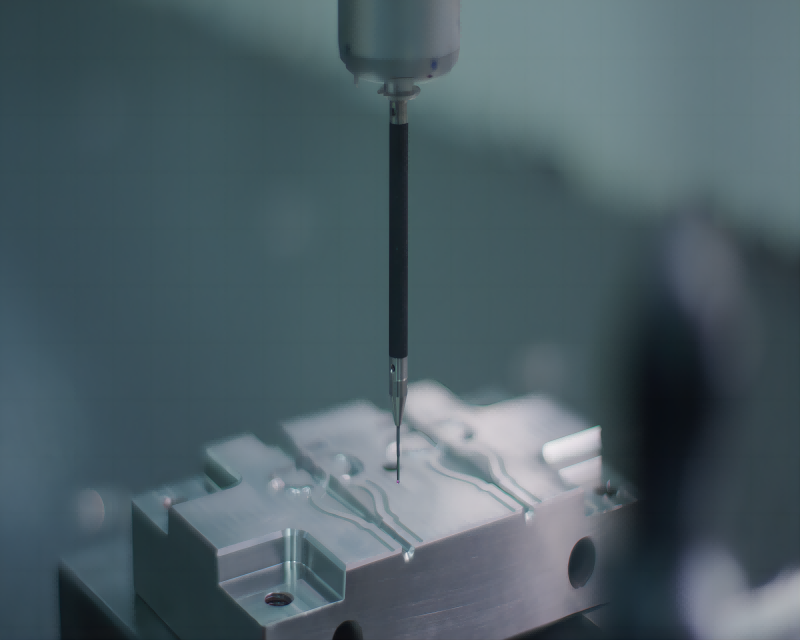

Tip Forming

Precision Medical Tubing Services Tip Forming involves shaping and forming the tips of medical-grade tubing materials to meet the specific requirements of medical device applications. The composition of the tubing used in this process varies depending on the desired properties and performance characteristics required for the medical device. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

- Tip Shapes: Demax offers a variety of tip shapes to suit different medical device requirements, including tapered tips, rounded tips, bullet tips, and custom-shaped tips. We can create tips with precise dimensions and angles to meet your application needs.

- Tubing Compatibility: Our tip forming services are compatible with a wide range of medical-grade tubing materials, including polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, and more. We ensure that the tip forming process maintains the integrity and properties of the tubing material, preserving biocompatibility and performance.

- Tolerance and Accuracy: Demax maintains tight tolerances and high levels of accuracy in the tip forming process, ensuring that the dimensions and geometry of the tips are consistent and precise. Our advanced equipment and quality control measures guarantee uniformity and reliability in formed medical tubing tips.

- Catheters: Formed tubing tips are commonly used in catheter assemblies to facilitate smooth insertion, navigation, and positioning within the body’s natural cavities.

- Endoscopic Devices: Formed tubing tips are utilized in endoscopic instruments for improved maneuverability, visualization, and control during minimally invasive procedures.

- Guidewires: Formed tubing tips serve as components in guidewires to facilitate navigation through blood vessels and other anatomical structures during diagnostic and interventional procedures.

- Biopsy Devices: Formed tubing tips are employed in biopsy forceps and other tissue sampling devices to enhance precision and control during tissue collection procedures.

Related products

-

Peelable Tube

The Demax Peelable Tube is an innovative medical device designed to provide easy and controlled access to catheters and guidewires during medical procedures. Crafted with precision and utilizing advanced materials, this peelable tube offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

-

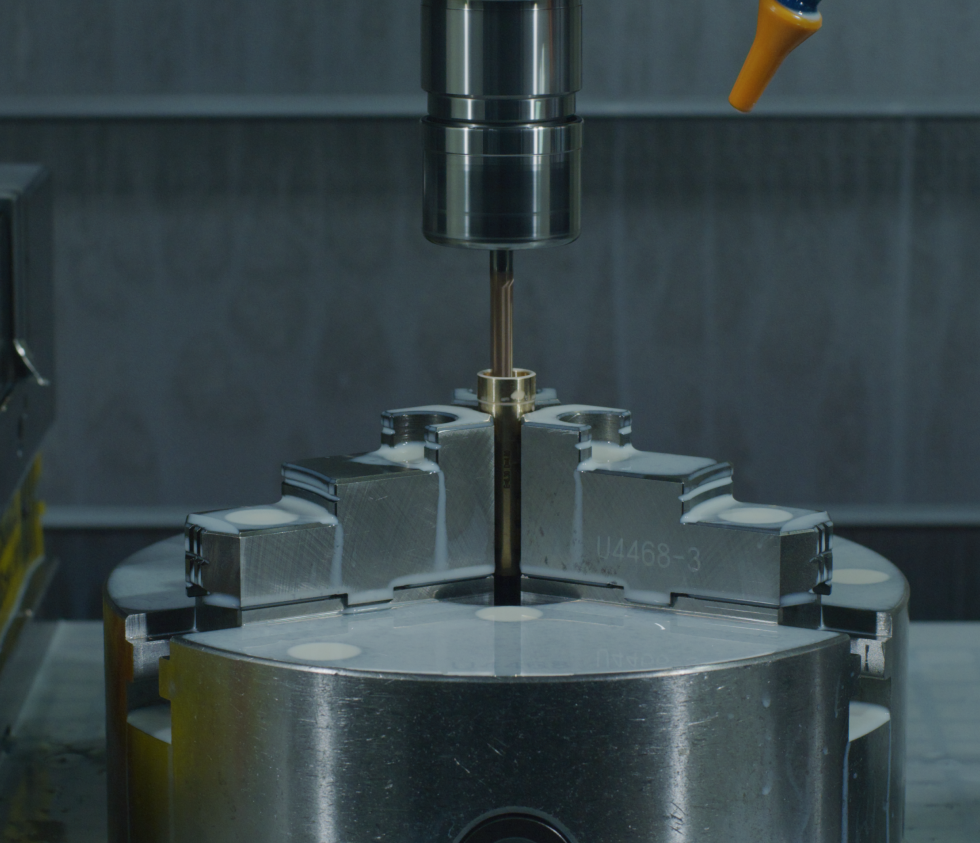

Hook Forming

Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, chosen for their exceptional mechanical properties, corrosion resistance, and biocompatibility. These materials undergo precise shaping processes to achieve intricate hook configurations tailored to specific medical device applications. With our commitment to quality and precision, Demax ensures that hook-formed components meet the rigorous demands of medical device manufacturing, contributing to the advancement of healthcare worldwide.

-

Microcatheter

Features:

1. PTFE inner layer allows for smooth passage for embolic agents;

2. Optimal trackability through tortuous anatomy;

3. Available in pre-shaped tip shape configurations for vessel engagement;

4. Four shapes provides more option for clinical usage;

5. 2.0F/2.2F/2.6F/2.8F models are available;

6. Hydrophilic coating technology, smoothly through the lesion. -

FEP Heat Shrink Tube

The FEP Heat Shrink Tube boasts a composition rooted in fluorinated ethylene propylene (FEP), a thermoplastic polymer renowned for its exceptional properties in medical applications.

FEP exhibits a unique combination of characteristics that make it ideally suited for medical tubing. Its molecular structure imparts remarkable clarity to the tubing, allowing for optimal visualization of fluids and instruments during medical procedures, essential for accurate monitoring and precise manipulation.