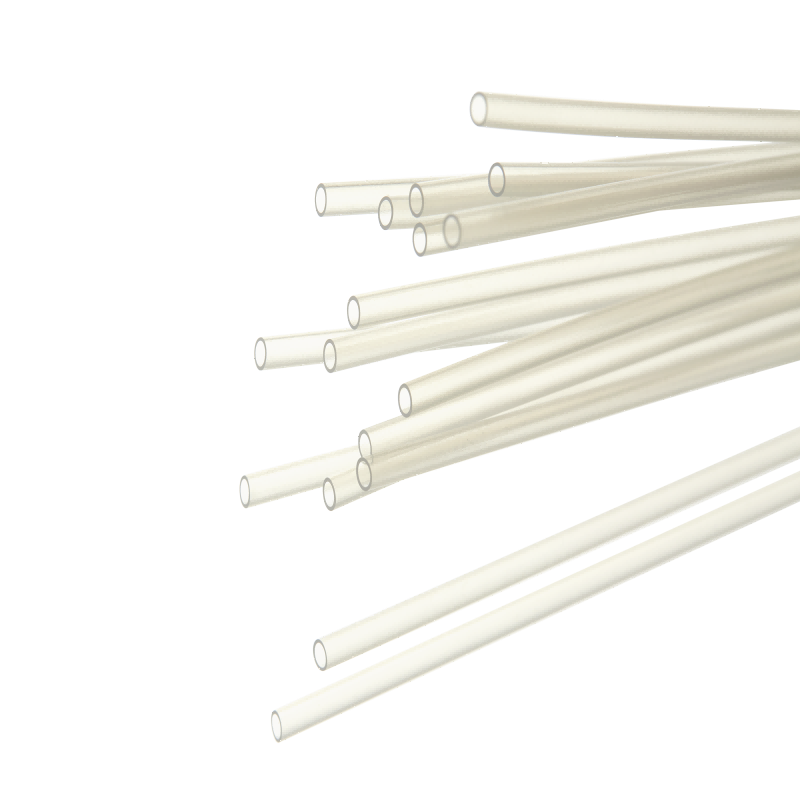

TPU Tube

Demax TPU tubes are meticulously crafted from Thermoplastic Polyurethane (TPU), a premium synthetic polymer renowned for its exceptional elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This composition ensures the tubes’ longevity and reliability, even in the most demanding conditions. Demax’s commitment to quality extends to every aspect of their manufacturing process, from sourcing the finest materials to employing advanced production techniques. The result is a TPU tube that meets stringent industry standards, providing customers with confidence and peace of mind in their critical applications. Whether in medical procedures, laboratory experiments, or industrial processes, Demax TPU tubes deliver unmatched performance and durability, making them the preferred choice for professionals across various sectors.

- Material Composition: TPU Tube ( Single Lumen Tube) are crafted from Thermoplastic Polyurethane, a synthetic polymer known for its elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This material ensures longevity and reliability in diverse operating conditions.

- Flexibility: TPU Tubes possess high flexibility, allowing them to bend and conform to various shapes and configurations without sacrificing structural integrity. This flexibility simplifies installation and enhances maneuverability in complex systems, reducing installation time and labor costs.

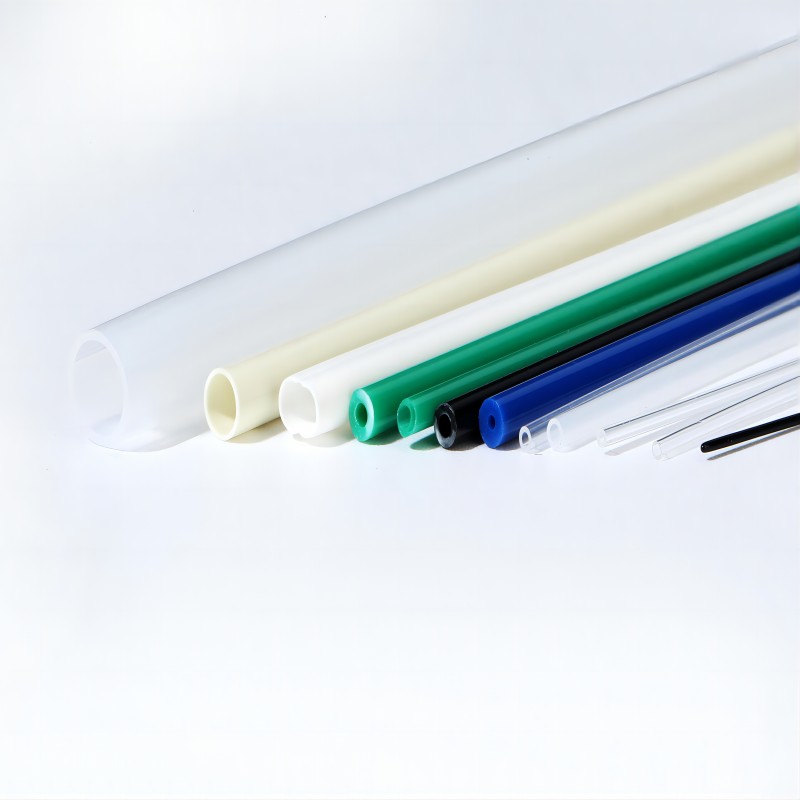

- Size Range: Available in a broad range of sizes, TPU Tubes cater to diverse application requirements. From small diameters suited for intricate medical procedures to larger diameters for industrial fluid handling, these tubes offer versatility to accommodate different fluid volumes and flow rates.

- Single Lumen Design: TPU Tubes feature a single lumen design with a seamless interior pathway, ensuring unobstructed fluid flow. This design is critical in applications where precise fluid control and consistency are essential, preventing blockages and maintaining optimal performance.

- Transparency: Many TPU Tubes are transparent or translucent, allowing for visual monitoring of fluid flow. This transparency facilitates real-time observation of processes, enabling operators to detect abnormalities promptly and ensure smooth operation.

| Outer Diameter | Tube Wall Thickness(mm) | ||

| Outer Diameter Specification(mm) | Outer Diameter Tolerance(mm) | Minimum Tube Wall Thickness(mm) | Tube Wall Thickness Tolerance(mm) |

| 0.5-10.0 | ±0.03 | 0.05 | ±0.03 |

- Medical: In the medical sector, it play a crucial role in applications such as catheters, IV lines, and respiratory tubing. They enable the safe and efficient delivery of fluids, medications, and gases within the body during surgical procedures, patient care, and diagnostic tests.

- Laboratory: Laboratories utilize TPU Tubes for fluid handling, chromatography, and sample analysis. Their flexibility and chemical resistance make them ideal for connecting equipment and facilitating precise fluid control in experiments and research activities.

- Industrial: Industrial processes rely on TPU Tubes for fluid transfer, chemical handling, and pneumatic systems. Their robustness and versatility ensure the smooth operation of machinery and processes in manufacturing, automotive, and other industrial sectors.

Related products

-

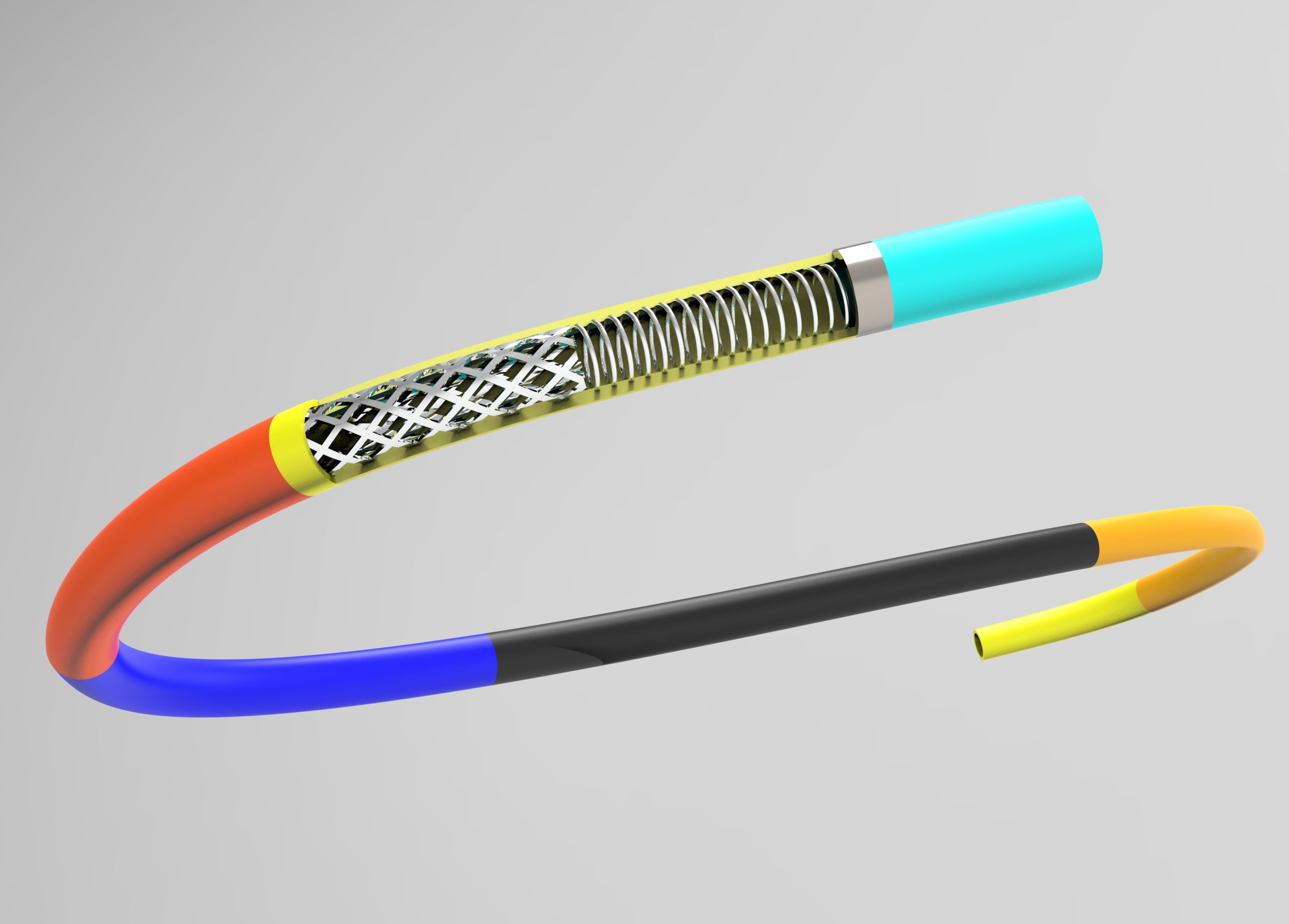

Braid & Coil Reinforcement Tube

The Demax Braid & Coil Reinforcement Tube is an innovative medical device designed to provide enhanced strength and flexibility for a wide range of medical applications. Crafted with precision and utilizing advanced materials, this reinforced tubing offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

-

ETFE Tube

ETFE tubes manufactured by Demax are crafted from high-quality ethylene tetrafluoroethylene (ETFE) polymer.

This fluoropolymer material offers exceptional chemical resistance, mechanical strength, and biocompatibility, making it ideal for medical device applications.

ETFE tubes undergo precise extrusion processes to achieve consistent dimensions, smooth surfaces, and reliable performance in medical settings.

-

PP Tube

The PP Tube is meticulously crafted from high-quality polypropylene, a thermoplastic polymer renowned for its exceptional chemical resistance, durability, and biocompatibility. This composition ensures that the tube is safe for use within the body and can withstand the rigors of medical procedures without compromising patient safety or device performance. Employing state-of-the-art manufacturing techniques, Demax ensures uniformity in dimensions and performance, producing PP Tubes that meet the highest standards of quality and reliability. With Demax’s PP Tubes, healthcare professionals can perform medical procedures with confidence, knowing that they have a dependable and effective tool at their disposal to deliver optimal patient care.

-

FEP Heat Shrink Tube

The FEP Heat Shrink Tube boasts a composition rooted in fluorinated ethylene propylene (FEP), a thermoplastic polymer renowned for its exceptional properties in medical applications.

FEP exhibits a unique combination of characteristics that make it ideally suited for medical tubing. Its molecular structure imparts remarkable clarity to the tubing, allowing for optimal visualization of fluids and instruments during medical procedures, essential for accurate monitoring and precise manipulation.