Precision engineering in coil reinforcement medical tubes involves the meticulous design and manufacturing of tubes with precisely controlled dimensions and tolerances, often incorporating reinforcing coils for added strength and stability. In the realm of medical devices, precision is paramount, as even minor deviations can impact functionality and patient safety. Demax exemplifies this commitment to precision through its R&D, innovation, and independent production practices. With a state-of-the-art production facility equipped with advanced cleanrooms, Demax ensures the highest standards of quality and reliability in its products. By continuously pushing boundaries and striving for perfection, Demax aims to elevate industry standards and contribute to global medical innovation efforts with cutting-edge medical equipment.

Basic Concepts

Explanation of Coil Reinforcement in Medical Tubes

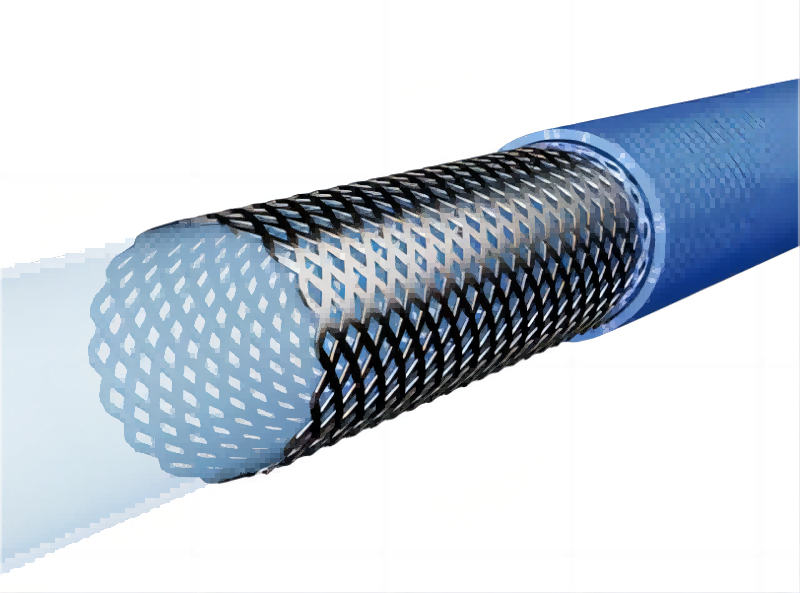

Coil reinforcement involves integrating coils, typically made of materials like stainless steel or nitinol, into medical tubes to enhance their strength, flexibility, and kink resistance. These coils are usually wrapped around the inner or outer surface of the tube. Provides structural support and prevents collapse or deformation during medical procedures. The arrangement and density of coils vary based on specific medical applications and performance requirements.

Importance of Precision in Medical Tube Manufacturing

Precision is crucial in medical tube manufacturing to ensure consistent quality, functionality, and safety of the final product. Precise dimensions and tolerances are essential for compatibility with medical instruments, seamless insertion into the body, and reliable performance during medical procedures. Any deviations from specifications can compromise the effectiveness of the tube and pose risks to patients’ health.

Materials Commonly Used in Coil Reinforcement Medical Tubes

Spiral reinforced medical tubing comes in a variety of materials. Among them, stainless steel and nitinol are the most common materials due to their excellent mechanical properties and biocompatibility. Stainless steel offers high strength and corrosion resistance, while nitinol provides exceptional flexibility and shape memory properties. Other materials, such as polymers, may also be used for specific applications. Offers advantages such as radiopacity or hypoallergenicity.

Design Considerations

Factors Influencing the Design of Coil Reinforcement Medical Tubes

The design of spiral reinforced medical tubing is influenced by a variety of factors. Include intended medical application, anatomical considerations, patient comfort, and procedural requirements. Factors such as tube diameter, coil density, pitch and configuration are carefully optimized. To achieve the ideal balance between strength, flexibility and maneuverability in the body.

Importance of Precise Dimensions and Tolerances

Precise dimensions and tolerances are critical in the design of coil reinforcement medical tubes to ensure compatibility with catheters, guidewires, and other medical instruments. Tight tolerances are necessary to maintain consistent performance and prevent issues such as leakage, tissue damage, or device malfunction. Furthermore, precise dimensions facilitate smooth insertion and navigation through the body’s complex anatomy, minimizing patient discomfort and procedural complications.

Balancing Flexibility and Strength in Design

Achieving the optimal balance between flexibility and strength is a key consideration in the design of coil reinforcement medical tubes. Although flexibility is critical to negotiate tortuous anatomical paths and minimize tissue trauma. Sufficient strength is required to support the structural integrity of the tube and resist deformation or collapse under various physiological conditions. Design modifications such as adjusting coil geometry, material selection, or wall thickness are employed to achieve the balance required for a specific clinical application.

Manufacturing Processes

Overview of Manufacturing Processes for Coil Reinforcement Medical Tubes

The manufacturing of coil reinforcement medical tubes typically involves several sequential processes, including tube extrusion, coil winding, heat treatment, and finishing. Tube extrusion forms the base polymer or metal tube, which is then precision-wound with coils using automated machinery. Heat treatment processes can be used to enhance the mechanical properties of the coil or the shape memory properties of Nitinol. Finally, finishing operations such as cutting, polishing and surface treatment are performed. To ensure that the final product meets quality standards and regulatory requirements.

Importance of Precision in Manufacturing Techniques

Precision is paramount in manufacturing coil reinforcement medical tubes to achieve consistent quality, dimensional accuracy, and performance characteristics. Advanced manufacturing techniques such as computer-controlled coil winding, laser cutting, and robotic assembly ensure tight tolerances and repeatability in production. Strict adherence to standardized protocols and quality control measures minimizes variability and ensures compliance with regulatory standards for medical devices.

Quality Control Measures During Manufacturing

Implement quality control measures throughout the manufacturing process. To identify and reduce any deviations from specifications or defects in the final product. Non-destructive testing methods such as dimensional inspection, visual inspection and imaging techniques are used to verify dimensional accuracy, coil integrity and surface quality. In addition, rigorous testing protocols may include mechanical testing, stress testing, and biocompatibility assessments. To ensure the safety and effectiveness of spiral reinforced medical tubes for clinical use.

Applications in Medicine

Various Medical Applications of Coil Reinforcement Medical Tubes

Coil reinforcement medical tubes find widespread use in various medical procedures, including:

- Angiography Catheter: Used for imaging blood vessels and delivering contrast agents during angiographic procedures.

- Guiding Catheter: Provides support and guidance for the advancement of therapeutic devices during interventional procedures such as angioplasty or stent placement.

- Micro Catheter: Enables access to small and tortuous vessels for targeted treatments such as embolization or drug delivery.

- Guiding Sheath: Facilitates the insertion and navigation of diagnostic or therapeutic devices into the vasculature with enhanced stability and control.

- Distal Access Catheter: Allows for precise access to distal vascular targets, particularly in neurovascular interventions.

Advantages over Traditional Tubing Designs

Coil reinforcement medical tubes offer several advantages over traditional tubing designs, including:

- Enhanced strength and kink resistance: The incorporation of coils increases the structural integrity of the tube. Reduced risk of kinking or collapse when navigating tortuous anatomical pathways.

- Improved pushability and trackability: The stiffness provided by coil reinforcement allows for better pushability and trackability. This promotes the smooth advancement and positioning of medical equipment in the body.

- Improved durability: Coil reinforcement increases the durability and fatigue resistance of medical tubing. Extends its service life and reduces the need for frequent replacement.

- Enhanced radiopacity: Certain coil materials, such as stainless steel, have superior radiopacity compared to polymer tubing. Improves visibility under fluoroscopy and facilitates precise device placement.

Case Studies or Examples of Successful Implementations

Examples of successful implementations of coil reinforcement medical tubes include:

- Interventional Cardiology: Coil-enhanced guide catheters have revolutionized the field of interventional cardiology. Minimally invasive treatment of coronary artery disease has been achieved. Improved surgical success rate and patient prognosis.

- Neurointerventional: Coil-reinforced microcatheters play a vital role in neurointerventional procedures. Enables neurosurgeons to access and treat complex vascular lesions with greater precision and safety.

- Peripheral vascular interventional therapy: Coil-reinforced guide sheaths promote the advancement of endovascular devices in peripheral vascular interventional therapy. Expanding treatment options for patients with peripheral artery disease.

Future Directions

Emerging Technologies in Precision Engineering for Medical Tubes

The assembly promises to revolutionize the precision engineering of medical tubing. These innovations provide greater design flexibility, customization and manufacturing efficiency. Paving the way for the development of next-generation medical devices with enhanced performance and functionality.

Potential Advancements in Materials and Manufacturing Processes

Ongoing research in materials science may lead to the discovery of novel materials with superior mechanical properties, biocompatibility, and radiopacity for coil reinforcement medical tubes. Additionally, advancements in manufacturing processes, such as microscale fabrication techniques and nanotechnology, hold promise for achieving higher precision, miniaturization, and cost-effectiveness in production.

Impact on the Medical Industry and Patient Care

ical industry and patient care. These innovations will enable clinicians to perform minimally invasive procedures with greater accuracy, efficiency and safety. This results in improved treatment outcomes, reduced complications and increased patient satisfaction. In addition, the development of innovative medical devices will drive advancements in healthcare services. And contribute to the advancement of medical technology.

Final Words

Precision engineering in coil reinforcement medical tubes represents a cornerstone of modern healthcare technology. Through careful design, manufacturing and application. These advanced devices provide unparalleled strength, flexibility and reliability during a variety of medical procedures. The commitment to precision exhibited by Demax drives innovation, sets new industry standards, and ultimately improves patient outcomes. As emerging technologies continue to shape the medical device manufacturing landscape. The future promises greater progress in precision engineering. Ultimately changing the way healthcare is delivered and experienced around the world.