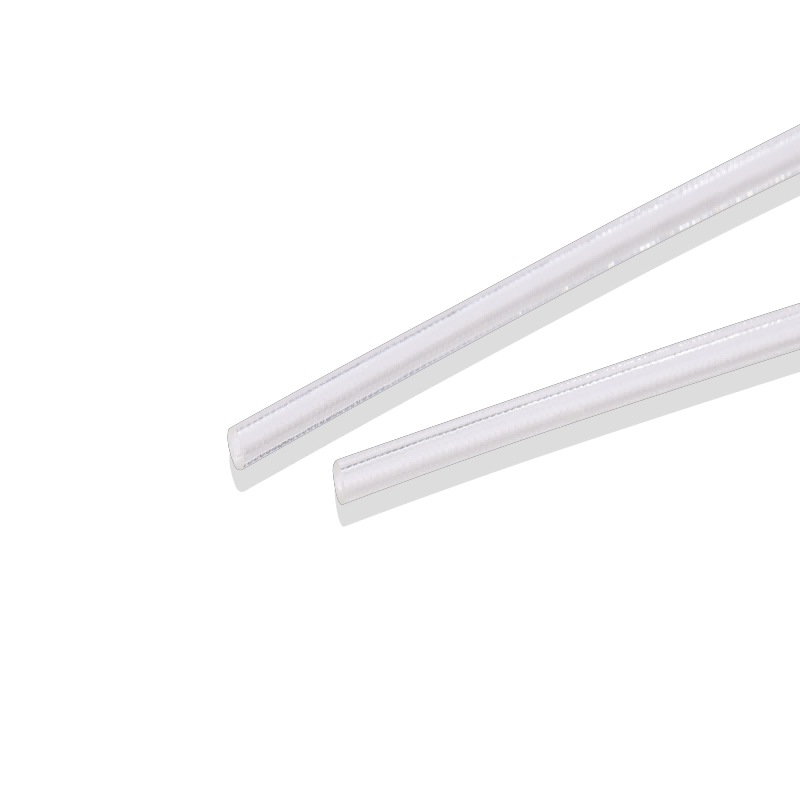

Properties of PU Braid Tube

Material Composition

Crafted from polyurethane, a versatile polymer known for its elasticity and mechanical strength, the PU braided tubing offers significant flexibility, which allows for easy handling during medical procedures. This flexibility ensures that the tubing can be bent or twisted without forming kinks, promoting smooth and consistent fluid flow for optimal performance.

Flexibility and Durability

The PU braided tubing is designed to meet the challenging demands of medical environments, showcasing exceptional durability. Its resistance to deformation under various pressures is essential, maintaining its structural integrity and ensuring reliable performance during extensive use. This durability is particularly valuable in dynamic clinical settings where equipment must withstand repeated use.

Resistance to Kinking and Collapsing

Enhanced with a braided layer, the tubing boasts increased strength, which significantly minimizes the risks of kinking and collapsing. This reinforcement is crucial for maintaining uninterrupted fluid flow, particularly under high-pressure conditions, ensuring that the tubing retains its shape and continues to function effectively.

Compatibility with Various Fluids

The tubing’s inner surface is designed to be smooth to facilitate optimal fluid flow and to minimize the potential for blockages. This smoothness decreases friction and turbulence, thereby enhancing the efficiency of fluid delivery. Additionally, the material of the tubing is highly resistant to the chemicals and solvents commonly used in medical settings, ensuring compatibility with a variety of fluids and medications while preventing degradation and maintaining fluid purity.

Potential Applications

Intravenous Therapy

PU braided tubing is integral to intravenous (IV) therapy, administering fluids, medications, and blood products. Its dependable performance ensures it remains indispensable in both clinical and emergency settings, where precise and reliable fluid delivery is crucial.

Enteral Feeding

This tubing plays a vital role in enteral feeding, enabling the safe and effective delivery of nutrition solutions and medications to patients unable to consume food orally. Its design ensures that nutrients are delivered directly to the gastrointestinal tract with minimal complications.

Endoscopy

In endoscopic procedures like gastroscopy and colonoscopy, the tubing is crucial for irrigation, suction, and insufflation. Its chemical resistance and durability allow it to meet the diverse requirements of gastrointestinal procedures efficiently.

Respiratory Therapy

In respiratory therapy, especially during mechanical ventilation and oxygen therapy, the structural stability of PU braided tubing under pressure is vital for delivering respiratory gases consistently and reliably to patients.

Urology Procedures

The tubing is also employed in urology to administer irrigation fluids and contrast media during procedures such as cystoscopy and ureteroscopy. Its flexibility and resistance to chemicals make it well-suited for the precise and demanding environments of urological interventions.

Advantages over Traditional Tubes

Enhanced Flexibility

PU braided tubing offers superior flexibility compared to traditional medical tubing materials like PVC or rubber. This enhanced flexibility allows for easier manipulation during medical procedures, reducing the risk of disruption and ensuring smoother, more efficient fluid delivery.

Improved Durability

PU braided tubing is made of a combination of polyurethane and braided reinforcement layers. Much more durable than traditional tubing. They can withstand repeated bending and pressure fluctuations without deforming or breaking. Thus extending service life and reducing the need for frequent replacement.

Resistance to Chemical Corrosion

PU braided tubing is highly resistant to chemicals and solvents used in medical environments, which traditional tubes might not withstand. This resistance helps maintain the integrity of the tubing when exposed to various pharmaceutical products and cleaning agents, thereby preventing contamination and ensuring patient safety.

Potential Cost-effectiveness

Despite the advanced materials and structures. But PU braided pipes are cost-effective in the long run due to their durability and longer lifespan. Minimize maintenance costs by reducing the frequency of tube replacements. These tubes provide an economically viable option for healthcare facilities.

Current Research and Development Efforts

Studies on Material Enhancements

Ongoing research focuses on improving the polyurethane formulations to enhance the physical and chemical properties of PU braided tubing. These studies aim to increase flexibility, strength, and resistance to environmental stressors, ensuring the tubing can meet the evolving demands of medical applications.

Testing for Safety and Efficacy

Rigorous testing protocols are in place to evaluate the safety and efficacy of PU braided tubing. These include tests for biocompatibility, durability under real-world conditions, and performance during critical medical procedures. Ensuring that the tubing adheres to stringent safety standards is paramount.

Integration with Advanced Medical Technologies

Research is also being conducted on how PU braided tubing can be integrated with advanced medical technologies such as smart pumps and real-time monitoring systems. These integrations aim to enhance the functionality of medical devices, providing more control and accuracy in fluid delivery.

Collaborative Efforts with Industry Partners

Collaborations with universities, research institutions, and other industry partners are crucial for fostering innovation and accelerating the development of next-generation PU braided tubing. These partnerships leverage shared knowledge and resources to tackle complex challenges and drive technological advancements.

Future Directions

Further Optimization of Material Properties

Future research will continue to focus on refining the material properties of PU braided tubing to enhance performance characteristics like elasticity, tensile strength, and chemical resistance. These improvements aim to address specific needs within different medical specialties and procedures.

Exploration of Novel Manufacturing Techniques

Advancements in manufacturing technology may allow for more efficient production of PU braided tubing, reducing costs and environmental impact. Exploring novel manufacturing techniques such as 3D printing could also enable customization of tubing for specific medical applications, providing tailored solutions for healthcare providers.

Integration with Emerging Technologies like IoT and AI

The combination of the Internet of Things (IoT) and artificial intelligence (AI) with PU braided tubing has the potential to revolutionize medical treatment. By embedding sensors and smart features, tubing can provide real-time feedback on fluid flow rate, pressure, and other key parameters. This improves patient care through precise and automated adjustments.

Expansion into New Industries and Applications

With the further development of the performance of PU braided tubes. It has opportunities to expand into new industries such as biotech, pharmaceuticals and even aerospace. Each of these areas can benefit from the unique properties of PU braided pipe. Opening up new applications and markets for this multifunctional material.

CONCLUSION

PU braided tubing offers a substantial upgrade from traditional medical tubing by delivering enhanced flexibility, greater durability, and superior resistance to chemical corrosion. These features, combined with its cost-effectiveness, establish it as a crucial component in contemporary medical environments. Through continuous research and development, its functions are improved and advanced technology is incorporated. The range of applications for PU braided tubing is expanding both inside and outside the medical field. As innovation advances and new manufacturing methods are explored. PU braided tubing is expected to become an increasingly important element in the healthcare sector. Provide safer, more efficient and adaptable solutions for patient care and medical procedures.