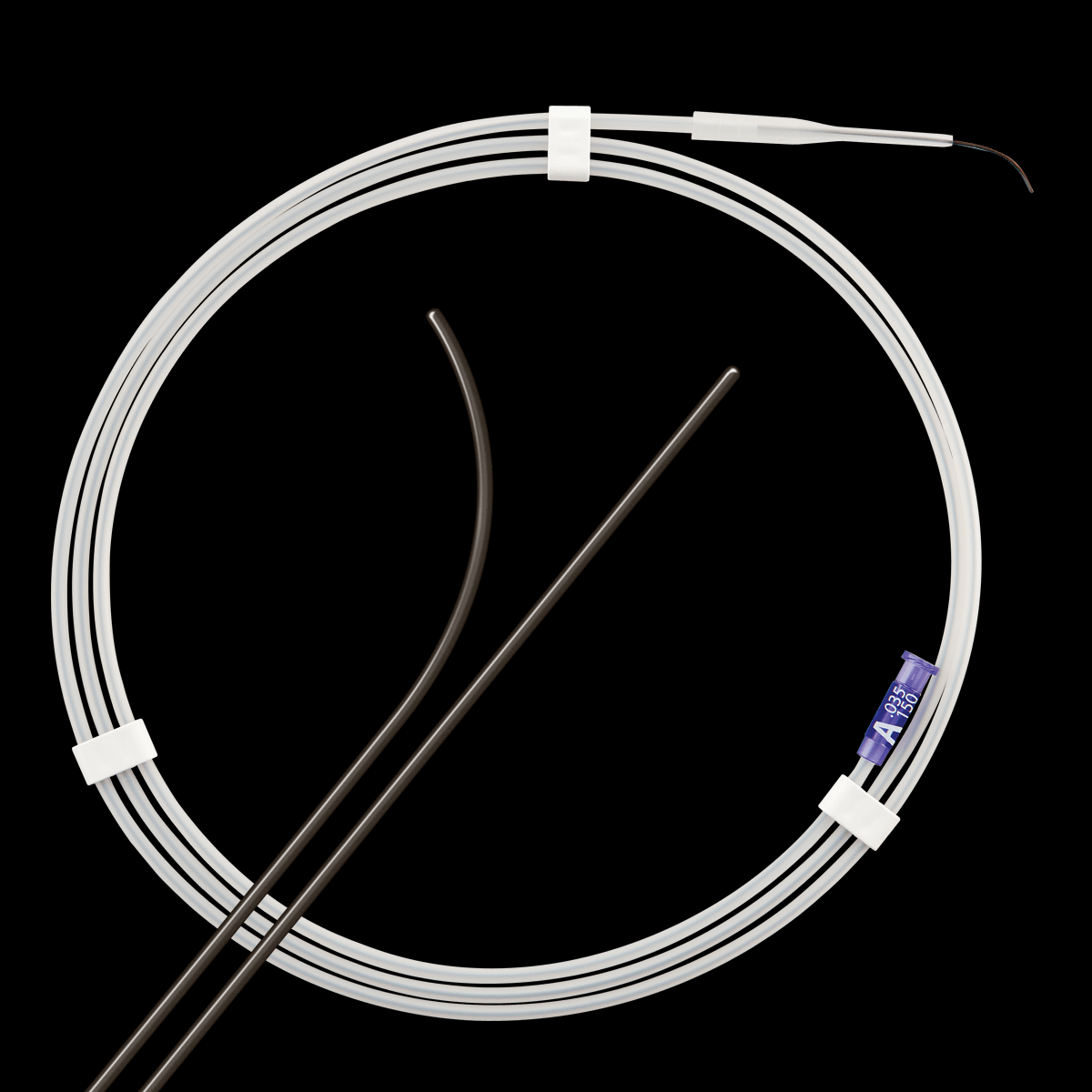

What is Hydrophilic Guidewire?

Composition of a Guidewire

The hydrophilic guidewire consists of two main parts:

- Core Wire: The strength and flexibility required to manoeuvre through complex capillaries are provided by this center shaft. Common materials include:

- Stainless Steel: Durable and reasonably priced.

- Nitinol: An alloy with form memory renowned for its exceptional pushability, kink resistance, and flexibility.

- Hydrophilic Coating: The key to its operation is the hydrophilic coating, a specific layer put to the core wire. Hydrophilic plastics include:

- Polytetrafluoroethylene (PTFE): A commonly used polymer renowned for having minimal friction.

- Hydrogels: Water-absorbent polymers that form a lubricating layer when exposed to moisture.

Hydrophilic Guidewire Characteristics

- Excellent Lubricity: The hydrophilic coating provides remarkable smoothness, reducing blood vessel friction for easy travel.

- Increased Flexibility: Designed to bend and negotiate complex capillaries without kinking.

- Fluoroscopic Visibility: Good vision under fluoroscopy guidance during surgeries ensured by radiopaque markers.

- Versatility: Available in a range of lengths, diameters, and tip designs to accommodate various interventional procedures.

Applications of Guidewires

These guidewires are extremely useful in a variety of minimally invasive treatments due to their versatility:

- Cardiovascular: Treatment of heart blockages via coronary angioplasty and stenting.

- Peripheral Vascular: Treating blockages in arteries leading to the legs using angioplasty and stenting.

- Neurovascular: Handling disorders of the nervous system, including stroke.

- Gastrointestinal: Enabling procedures such as Endoscopic Retrograde Cholangiopancreatography (ERCP).

- Urological: Making the ureters accessible for different types of procedures.

Benefits of Hydrophilic Guidewires in Angioplasty

Compared to conventional guidewires, hydrophilic guidewires offer several important features that improve patient outcomes and procedure efficiency:

- Improved Trackability: The lubricating coating reduces blood vessel friction, enabling smooth navigation through convoluted paths.

- Decreased Trauma: Lower friction reduces trauma to artery walls, decreasing complications and speeding up recovery.

- Enhanced Procedural Success: Smooth navigation and reduced vascular trauma increase the success rate of interventional operations.

- Enhanced Efficiency: Shorter procedure durations, less patient discomfort, and potentially lower medical expenses.

Considerations for Guidewires

Although hydrophilic guidewires have several benefits, certain considerations ensure patient safety and optimal performance:

- Handling: Proper handling methods are essential to preserve the hydrophilic coating’s integrity.

- Catheter Compatibility: Ensuring compatibility between the guidewire and other devices used in the process is crucial.

- Catheter Selection: Choosing the right guidewire size and tip configuration for the particular surgery ensures optimal navigation and outcomes.

- Allergic Responses: Although rare, allergic responses to the components in the hydrophilic coating may occur in some individuals.

Future of Hydrophilic Guidewires

The following innovations are keeping guidewire development moving forward:

- Enhanced Coatings: Technological advancements offer more lubrication, reducing friction and improving navigation.

- Integrated Imaging: Future versions may incorporate imaging modalities for real-time viewing during navigation.

- Patient-Specific Customization: Customized guidewires that navigate distinct vascular channels more effectively.

Hydrophilic Guidewire Safety Measures

To ensure maximum safety when using these guidewires, adhere to these important guidelines:

- Inspection: Regularly check the guidewire for damage indicators such as kinks or deterioration of the coating.

- Instructions: Follow the manufacturer’s instructions for handling, use, and compatibility with other devices.

- Disposal: Dispose of discarded guidewires according to medical waste standards to avoid contamination and environmental risks.

Hydrophilic Guidewire Training & Education

To maximize the application of these guidewires, healthcare personnel must have the appropriate training:

- Training Programs: Specific programs instruct users on how to choose guidewires, handle them safely, and use them with other interventional devices.

- Continuing Education: Regular updates on technological advancements and best practices.

- Training with Simulation: Simulation models enable hands-on practice and skill improvement using these guidewires.

Regulatory Considerations for Guidewires

Hydrophilic guidewire development and application are subject to stringent regulations:

- Manufacturing Standards: Adherence to regulatory standards such as ISO 13485.

- Approval Procedures: New designs or revisions require approval by regulatory organizations like the FDA.

- Post-Market Surveillance: Monitoring guidewires post-market introduction to identify and resolve potential safety issues.