Multilayer Tubing: Robustness and Adaptability

The advantages of many materials are combined in multilayer tubing to provide a single, high-performing solution. Picture minuscule tubes with discrete layers, each selected for certain characteristics. This cutting-edge technology provides:

- Increased Durability:

When compared to single-material tubing, several layers can offer better chemical resistance, pressure management, and overall longevity.

- Material Versatility:

While exterior layers concentrate on strength or barrier qualities, inner layers may give priority to flexibility or fluid compatibility.

- Targeted Applications:

It meets a variety of purposes, from industrial applications (high-pressure resistance) to medical devices (biocompatible layers).

- Multilayer Tubing: Purposes

- Enhanced Mechanical Strength:

Consider a tube with an inner layer that stresses flexibility and an exterior layer that is strong and resistant to pressure. When compared to conventional tubing, this layered construction greatly increases the total mechanical strength, which makes it perfect for demanding applications.

Multilayer tubing enables environment-specific customisation. Consider an inner layer made of a substance resistant to chemicals that shields the flow from abrasive fluids. Furthermore, outside layers are ideal for a variety of industrial or plumbing applications as they may be made to tolerate both high and low temperatures.

- Tailored Features for Various Needs:

Its versatility is what makes it so beautiful. Through meticulous material selection for every layer, engineers can produce tubes with precisely the right qualities for certain uses. It offers an unparalleled level of customisation that ordinary pipes just cannot equal. It offers possibilities for temperature-resistant settings in industrial settings as well as biocompatible layers for medical equipment.

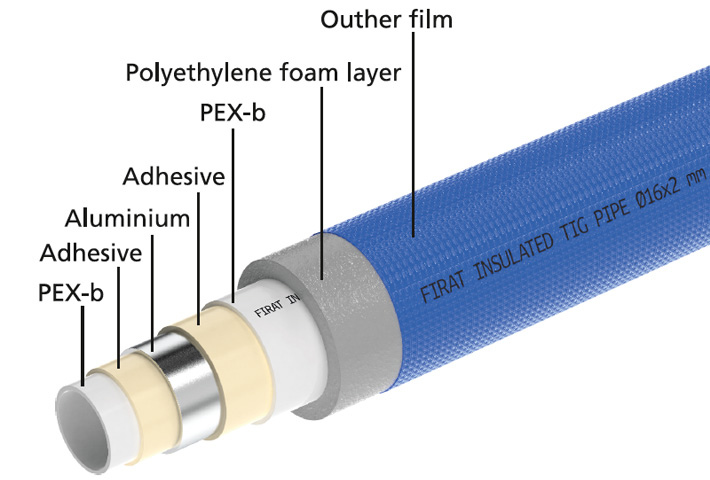

Multilayer Tubing: A Symphony of Layers

- Inner Layer:

This layer frequently gives priority to characteristics like compatibility with certain fluids or smoothness to reduce friction during fluid movement. The inner layer may be biocompatible when used in medical applications.

- Layer of Barrier:

This layer serves as a protector, keeping the inner and outer layers from interacting in an unwelcome way. It is not always present. It might be used, for instance, to stop chemicals or gases from seeping through.

- Outer Layer:

The outer layer is concerned with resistance to the environment and structural support. It may be selected because of its resilience to severe chemicals or temperature changes, or because of its capacity to endure pressure.

Building a Multilayer Masterpiece: Manufacturing Processes of Multilayer Tubing

Multilayer tubing is more than simply a brilliant idea—it is made possible by complex production procedures. These are the two main techniques:

- Coextrusion:

Visualise molten plastic dancing in unison. Multiple layers can be extruded simultaneously via a single die thanks to coextrusion. Each layer emerges smoothly together to form a robust tube. Accurate material distribution and uniform layer thickness are guaranteed by this effective procedure.

- Bonding:

Several applications may employ separate pre-formed layers. Adhesives and welding are examples of bonding processes that are useful in these situations. By meticulously joining the layers, these techniques guarantee a finished product that is both structurally robust and leak-proof.

Applications:

- Automobiles:

It is essential under the engine. Multilayer technology is frequently used in coolant hoses, brake lines, and fuel lines. These tubes provide smooth operation and long-lasting performance with their outstanding pressure resistance, great temperature tolerance, and chemical compatibility with vehicle fluids.

- Medical:

It rises to the challenge of providing precision, which is critical in the healthcare industry. While exterior layers may offer further advantages like strength for IV lines or flexibility for catheters, biocompatible interior layers guarantee patient safety. The safe and dependable administration of drugs and fluids is made possible by this technique.

- Food packing:

A successful combination for food packing is multilayer tubing. Outer layers can offer more defence against environmental elements like light or oxygen, while inside layers may emphasise food-grade safety and reduce permeability. This keeps food goods fresh and of high quality while guaranteeing a prolonged shelf life.

- Industrial:

It is ideally suited for applications ranging from complex pneumatic systems to high-pressure hydraulic lines. It is perfect for a variety of industrial applications because of its resistance to severe chemicals, intense temperatures, and high pressure, all of which ensure dependable and effective performance.

Multilayer Tubing: Exceptional Benefits That You Can’t Miss

- Improved Performance:

Consider exceeding the capacities of conventional tubes. Each layer of a multilayer structure can have targeted qualities. In comparison to single-layer tubes, this results in better temperature tolerance, higher chemical compatibility, and stronger pressure resistance, which all contribute to overall improved performance.

- Customized Solutions for Particular Needs:

Through careful layer-by-layer material selection, multilayer tubing may be tailored to meet particular needs. This makes it possible to use food-safe materials for packaging, high-pressure resistance in industrial settings, and biocompatible choices in medical applications.

- Durability and Reliability You Can Trust:

You can rely on the durability and dependability of multilayer tubing since it is made to last. The overall strength, chemical resistance, and resilience to high temperatures are all improved by the mix of layers. In comparison to single-layer alternatives, this results in increased durability and dependability, assuring long-lasting performance and lowering the possibility of leaks or breakdowns.

Challenges:

- Complex Manufacturing:

Precise control and specialised equipment are needed to create these complex tubes. Precise calibration of coextrusion operations is necessary to provide uniform layer distribution and prevent errors. Production may be more difficult due to its intricacy than with single-layer tubing.

- Cost considerations:

Compared to single-layer tubes, the elaborate production process and speciality materials sometimes result in a greater cost. However, multilayer tubing may end up being a more affordable option in the long run due to its improved performance and durability.

- Possibility of Delamination:

Delamination is the splitting of layers due to improper bonding or incompatibility between layers. It is essential to minimise this risk and guarantee a strong, cohesive tube by careful material selection, efficient production techniques, and stringent quality control procedures.

Multilayer Tubing: An Overview of Future Trends

- Next-Gen Materials:

As material science advances, new materials for every layer will be created, further improving properties like temperature tolerance, chemical compatibility, and pressure resistance.

- Smart Functionality:

Picture sensors integrated right into the tubes! Smart feature integration, such as temperature or pressure monitoring, may completely transform safety and maintenance procedures across a range of sectors.

- Breaking New Ground:

This technology is going to be used in progressively more demanding applications as it advances. For crucial jobs, renewable energy systems and aerospace exploration may make use of its power and adaptability.

Conclusion:

Demax concentrates on every technical aspect to offer a comprehensive solution for sterile, single-use medical equipment. Our knowledgeable, multilingual sales staff and after-sales support system can react to client demands quickly.