What is PEBAX Tubing?

PEBAX tubing is a distinctive and adaptable choice in the fluid transfer industry. It is made of a unique thermoplastic elastomer (TPE) substance known as PEBAX. Compared to rigid tube choices, this tubing has exceptional flexibility, which makes it simpler to install and work inside fluid transfer systems. Don’t let its adaptability deceive you.

This tubing provides dependable performance in demanding applications because of its remarkable strength and endurance. This tubing is a great option for a variety of sectors, especially those that need fluid transmission in confined places or sophisticated system designs due to its unique mix of toughness and flexibility.

PEBAX Tubing: A Powerhouse of Performance Components:

PEBAX tubing is more than just a versatile choice for transferring fluids. It excels in a variety of applications thanks to its impressive array of features, which include:

This tubing has exceptional elasticity, making complicated system routing and installation simple. Because of its elasticity, the tubing keeps its shape even after being bent or compressed.

- Lightweight:

PEBAX provides notable weight reductions as compared to other conventional tube materials. Because of this, it is perfect for uses where reducing weight is essential, including in aircraft or medical devices.

- Abrasion Resistance:

This tubing resists abrasion and can withstand normal wear and tear. It is a dependable option for situations where the tube may come into contact with friction or rubbing because of its remarkable abrasion resistance.

- Chemical resistance:

PEBAX ensures the safe and dependable transport of different fluids without deterioration by providing good resistance to a variety of chemicals.

- Low Moisture Absorption:

In certain situations, moisture absorption might be detrimental. Because these tubing absorb little moisture, it is a good option for areas where controlling moisture is essential.

Where PEBAX Tubing Shines: Common Applications:

This tubing is a flexible solution for a wide range of applications due to its unique mix of features, which include:

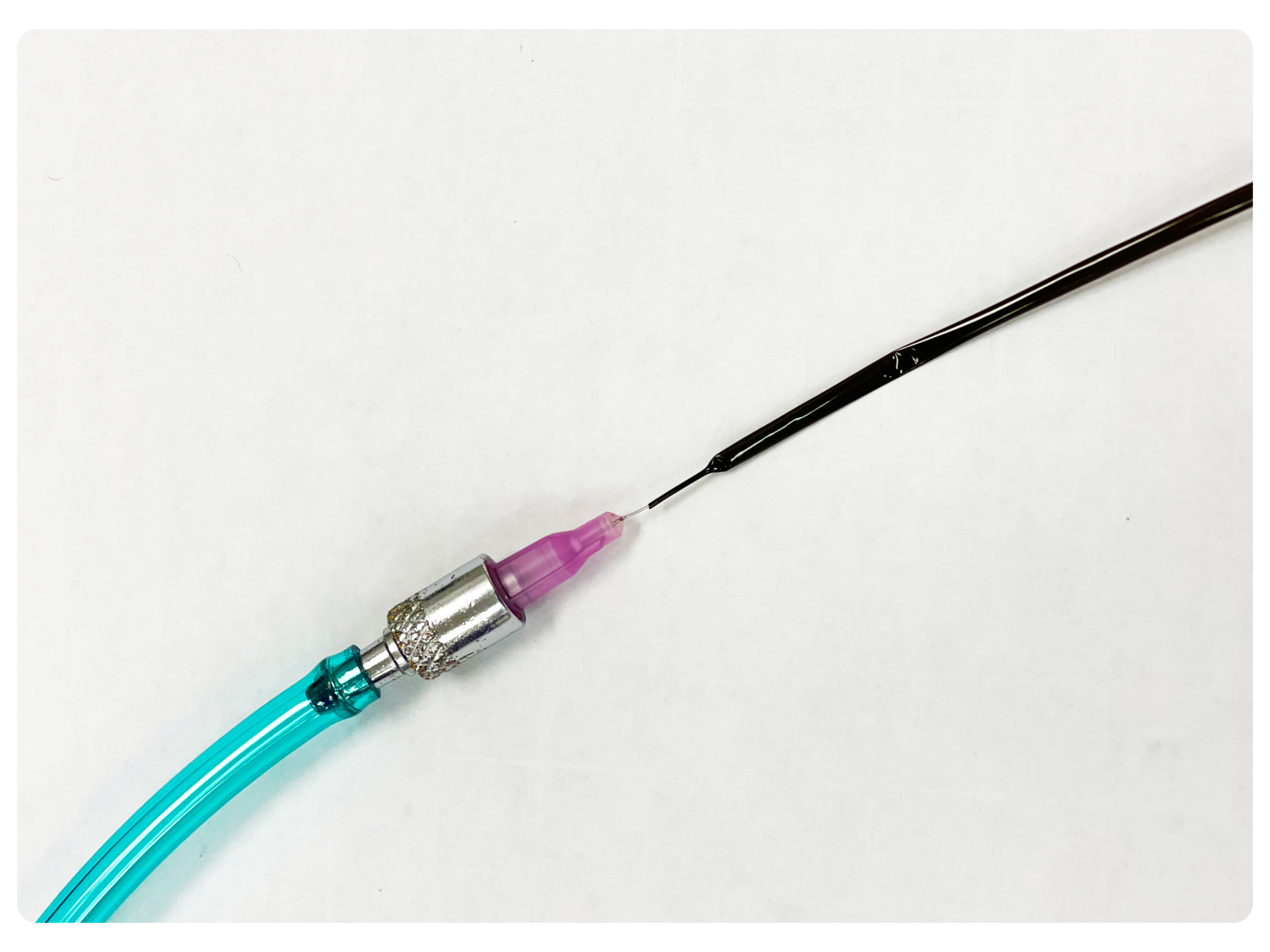

- Medical Devices:

These tubing are biocompatibility, flexible, and kink resistant making it a reliable option in the medical industry for anything from balloons and IV lines to catheters and other medical equipment.

- Sports Equipment:

Visualize achieving optimal performance while wearing your gear. Because of its flexibility and low weight, this tubing is used to make lightweight, high-tech sports equipment that improves comfort and movement.

- Industrial Machinery:

In industrial environments, dependability and durability are crucial. Because PEBAX tubing is resistant to chemicals and abrasion, it is a useful part of industrial machinery that guarantees long service life and smooth operation.

Beyond Flexibility – A Multitude of Advantages:

This tubing is not merely readily bowed. Made from a cutting-edge thermoplastic elastomer (TPE) known as PEBAX, it provides a special set of characteristics that add up to several benefits for demanding applications. Let’s examine the main advantages that set tubing apart:

Don’t let its adaptability deceive you. This tubing is incredibly resilient and able to tolerate harsh environments without losing functionality. It is perfect for applications that need to be reliable and simple to use at the same time because of this special combination.

- Superior Chemical Resistance:

When it comes to fluid transmission, peace of mind is crucial. Excellent resistance to a broad variety of chemicals is provided by PEBAX tubing. This makes it appropriate for a wide range of applications across industries by guaranteeing the safe and dependable transport of different fluids without deterioration.

- Biocompatible for Sensitive Applications:

In medical environments, biocompatibility is essential. For medical equipment that comes into touch with the body, PEBAX tubing performs admirably in this regard, making it a reliable option. This lowers the possibility of problems and guarantees patient safety.

A Shaped Solution – The Manufacturing Process

PEBAX tubing is carefully manufactured via an extrusion process; it is not just born. This process turns the basic material, PEBAX pellets, into the appropriate tube shape using specialized machinery.

- Extrusion:

There are numerous crucial processes in the extrusion process for this tubing:

- Preparation:

To guarantee ideal consistency and avoid moisture-related problems during extrusion, PEBAX pellets are dried.

- Melting and Mixing:

To create a homogeneous consistency, the dry pellets are put into an extruder and melted and well combined.

- Shaping:

Next, a well-crafted die is used to push the molten PEBAX through. The molten plastic is shaped by this die into the appropriate tube profile, which includes the wall thickness, diameter, and even possibly intricate forms.

- Cooling and Finishing:

After extrusion, the tube is chilled and solidified in a regulated environment. It then goes through finishing procedures including cutting and inspection to make sure it satisfies the requirements.

PEBAX Tubing: Ensuring maintenance and care:

It’s really easy to maintain your tubing! Here’s how to guarantee lifespan and peak performance:

- Gentle Cleaning:

Use lukewarm water and mild soap for regular cleaning. Steer clear of abrasive cleansers and strong chemicals since they might cause surface damage to the tubing.

- Chemical Compatibility:

Verify that fluids are compatible with PEBAX before handling them. Steer clear of extended exposure to strong chemicals since this might damage the tubing.

- Cool and Dry Storage:

Keep your tubing in a cool, dry location when not in use. Steer clear of extreme heat or intense sunshine since they may eventually alter the tubing’s characteristics.

PEBAX Tubing: Evolving to Meet Future Demands:

This tubing has a bright future ahead of it. Ongoing research and development is concentrated in the following areas:

- Improved Properties:

Researchers are always looking for methods to make tubing even better in terms of its resistance to temperature changes, chemical compatibility, and even biocompatibility for cutting-edge medical applications.

- Introducing Novel Apps:

These tubing’s special qualities continue to stimulate research into new uses. This may result in its application in cutting-edge disciplines or ground-breaking discoveries within already established ones.

- Improvements in Manufacturing:

Innovation isn’t limited to the substance. Enhancing productivity, cutting costs, or even producing even more complex tube forms for specific applications might result from research into better manufacturing processes for tubing.

Conclusion:

Its special combination of benefits makes it a high-performance, adaptable option for demanding applications. Visit Demax to discover the options. Speak with our staff right now to see how PEBAX tubing may improve the efficiency of your applications.