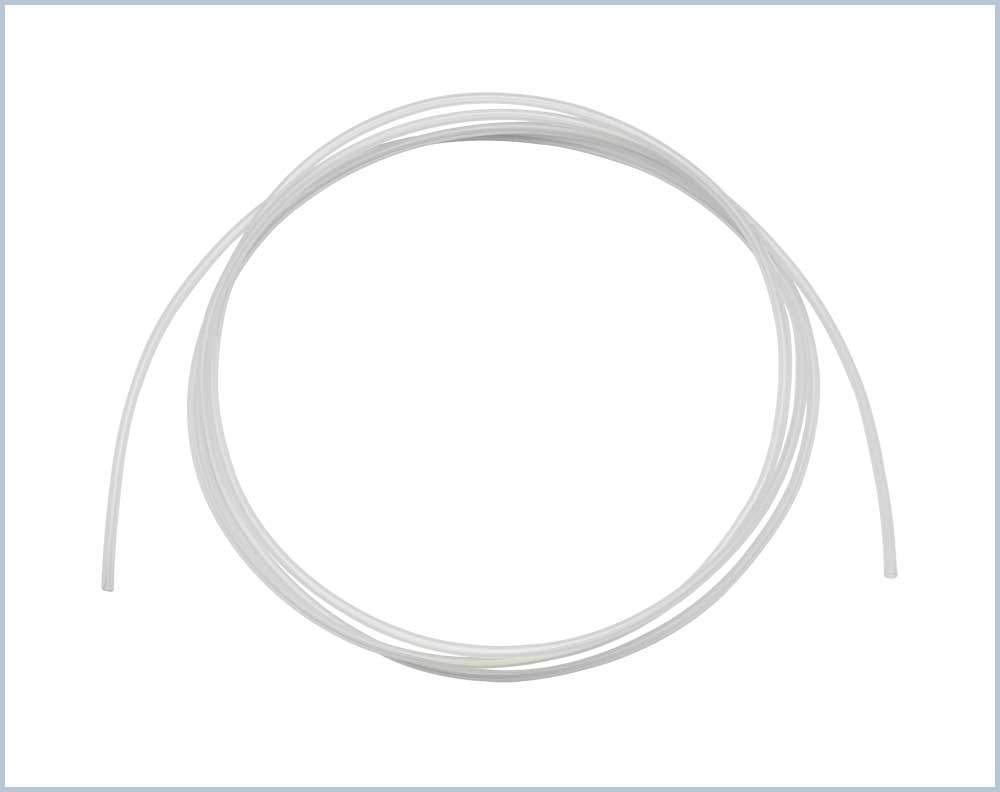

What is PTFE Tubing?

PTFE tubing is a high-performance, multipurpose plastic tubing solution that is sometimes referred to as Teflon tubing. It is composed of polytetrafluoroethylene (PTFE) and has a special set of qualities that make it perfect for a range of demanding applications. Suitable for difficult situations, it can withstand temperatures ranging from cold (-450°F) to very hot (500°F). It is safe to use with harsh fluids and solvents because it is inert to the majority of substances. Frictionless qualities reduce accumulation and encourage fluid flow. Applications involving food, drinks, and medicinal usage are safe to use.

Properties of PTFE Tubing: A Winning Combination for Diverse Applications

Teflon tubing, also referred to as PTFE tubing, is a popular option in a variety of demanding applications due to its exceptional combination of characteristics. Let’s examine some of its salient properties:

- Chemical Resistance:

The chemical inertness of PTFE is remarkable. A wide variety of substances, including strong acids, bases, and solvents, may be handled by it without risk. Because of this, it is perfect for use in severe fluid applications, labs, and chemical processing facilities.

- Temperature Resistance:

From extremely high temperatures (500°F) to cryogenic (-450°F), these tubing can withstand a broad range of temperatures. This enables it to perform successfully in challenging conditions where other materials could break down.

- Non-Stick Surface:

PTFE’s very low coefficient of friction produces a surface that is nearly frictionless, allowing for effortless flow on a non-stick surface. This results in little accumulation and wear by promoting smooth fluid movement. Because of this characteristic, it is ideal for applications like fluid transfer lines or food and beverage processing, where a smooth and efficient flow is essential.

- Flexibility:

This tubing has a certain amount of flexibility that permits modest bending and shaping, even if it isn’t as flexible as some other tube materials. Because of this, it may be used in a variety of situations where some formability is necessary without sacrificing any of its other excellent qualities.

Applications of PTFE Tubing: Unrivaled Performance across Industries

Because of its remarkable qualities, PTFE tubing is used in many different industries. Here’s an example of how many industries make use of its special qualities:

- Chemical Industry:

This tubing securely handles harsh chemicals, acids, and solvents because of its unparalleled chemical resistance. In chemical processing facilities, it is a dependable option for sampling lines, pipelines, and the transfer of hazardous fluids.

- Medical Applications:

Because of its biocompatibility, PTFE is perfect for use in medical equipment such as catheters and needles. Because of its low friction surface, patients experience less discomfort during insertion and fluid flow.

Crafting Excellence: The Manufacturing Process of PTFE tubing:

The exceptional qualities of these tubing are the result of a special production technique. Here is a condensed overview of the crucial steps:

- Extrusion:

Because of PTFE’s high melt point, a unique methodology is required, in contrast to conventional procedures. A lubricant is combined with fine PTFE powder, which is then pushed through a mold at high pressure to form a continuous tube.

- Sintering:

Sintering is the process of heating the extruded tube. In doing so, the lubricant is eliminated and the PTFE particles are fused to form a solid structure with the appropriate shape and characteristics.

To achieve precise specifications and final dimensions, the tube may go through further steps like chilling, calibrating, or surface polishing after sintering.

Choosing Wisely: Considerations for Using PTFE Tubing:

Discussing considerations for using these tubing can lead Selecting the Right Tubing for Your Needs. It has amazing qualities, but for long-lasting use and best performance, there are a few important things to keep in mind:

- Compatibility:

Make sure the materials are compatible with the gases or fluids being conveyed. Despite their extreme resistance, some chemicals could need for different kinds of tubing.

- Handling Precautions:

Sharp items have the potential to nick or cut PTFE. Its integrity must be maintained throughout installation and use, therefore handle it carefully.

- Installation:

To guarantee a leak-proof and secure connection, appropriate fitting selection and installation procedures are crucial. It is advised to review manufacturer guidelines for particular applications. You may optimize the advantages of these tubing and guarantee its dependable performance in your project by being aware of these factors.

Maintaining Peak Performance: Caring for Your tubing

Although this tubing requires little upkeep, correct handling increases its longevity and guarantees peak performance. Observe the following:

- Cleaning:

Use warm water and a light detergent for regular cleaning. Steer clear of strong substances that might damage the tubing.

- Inspection:

Check the tubing on a regular basis for wear, fractures, or cuts. As soon as possible, replace broken tubing to stop leaks and malfunctions.

You can ensure years of trouble-free performance from your PTFE tubing by adhering to these easy measures.

Environmental Impact of these Tubing: A Responsible Choice

The outstanding resilience of this tubing has advantages for the environment. Its extended lifespan lessens the requirement for regular replacements. But there are a few things to keep in mind:

- Recyclability:

Although PTFE isn’t now extensively recyclable, research is being done to find better recycling techniques. It is essential to dispose of waste responsibly.

- Disposal:

To find the right disposal choices, check your local legislation. Because there might be issues with emissions, incineration should be avoided. Think about appropriate methods for managing garbage. You may reduce the environmental effect of this tubing by being aware of these factors and looking into appropriate disposal choices.

The Future trends: Innovation and Responsibility

This tubing is still developing, and there are some interesting new developments coming very soon:

- Advances in Material Science:

The goal of research is to preserve key characteristics while improving qualities like heat resistance and flexibility. This may lead to even more difficult applications.

- Sustainability Initiatives:

Producers are looking at recyclable PTFE formulations as well as environmentally suitable substitutes for production procedures. This emphasis on sustainability guarantees this priceless substance a responsible future.

Conclusion:

PTFE tubing is a dependable and adaptable material that is used in many different industries because of its remarkable combination of chemical resistance, temperature tolerance, non-stick surface, and electrical insulation. As of right now, Demax holds a 30% market share for coronary artery attachments throughout several nations thanks to its top-tier sales network.