Unveiling the Advantages: Benefits of OEM Urologic Hydrophilic Coated Guidewires

- Better patient outcomes:

Urologic Hydrophilic Coated Guidewire OEM offers patients a more comfortable experience with less friction.

- Improved procedural efficiency:

Faster and more effective operations are made possible by seamless navigation.

- Decreased risk of complications:

The risk of catheter-related problems is decreased when tissue injury is minimized.

Key features of urologic hydrophilic coated guidewires:

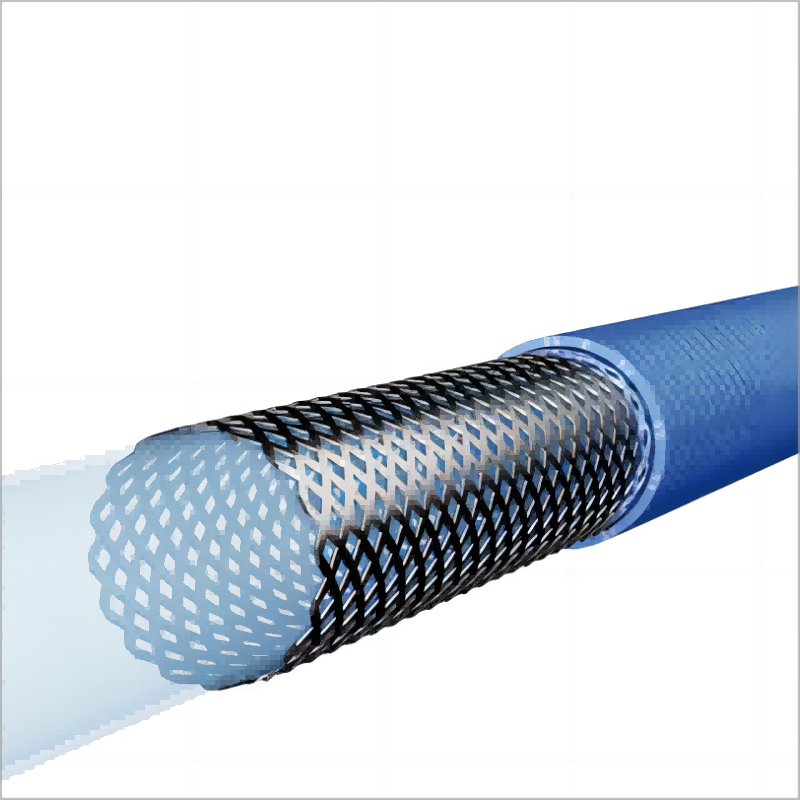

- Hydrophilic coating:

When damp, this water-loving surface forms a lubricating layer that reduces friction and promotes easy catheterization.

- Kink resistance:

Throughout the operation, accurate control and navigation are ensured by the core wire’s design to resist kinking.

- Atraumatic tip:

During insertion, there is less chance of tissue injury because of the soft, atraumatic tip.

Looking for Urologic Hydrophilic Coated Guidewire OEMs?

Working with an Original Equipment Manufacturer (OEM) provides medical device firms looking to source high-quality urologic hydrophilic coated guidewires with a number of benefits.

- Customization:

OEMs can modify guidewire features including length, diameter, and tip arrangement to suit particular requirements. This entails adjusting the intended functions, length, diameter, and tip configuration to meet your unique requirements.

- Cost-effectiveness:

Using the production skills and experience of an OEM may often result in lower costs than doing it yourself. OEM manufacture may frequently be more affordable than internal production, particularly for businesses without specialized manufacturing capabilities. Resources can now be allocated to various areas of your company.

- Quality assurance:

Reputable OEMs uphold stringent quality control measures to guarantee reliable performance and patient safety. The highest safety and performance criteria are met by your guidewires thanks to the strict quality control standards upheld by reputable OEMs. Both patients and medical personnel gain trust as a result of this.

Demax is the reliable partner for Urologic Hydrophilic Coated Guidewire:

We discuss automation, semi-automation, and conventional industrial methods in their entirety. Furthermore, we have been able to autonomously create intelligent production lines, obtain real-time production data, and guarantee lean manufacturing thanks to a mix of state-of-the-art machinery and the most recent communication technologies. High-end production has finally resulted in a significant improvement in the quality of our products.

Quality is the outcome of carefully analyzing every procedure. To offer a comprehensive solution for single-use, sterile medical equipment, we pay close attention to every technical aspect. Meanwhile, there is continuous progress being made in the fields of coating preparation and coating technology, molding technology, welding technology, bonding technology, and testing technology.

How urologic guidewires work?

- Insertion:

The guidewire is inserted through the urethra and travels through the urinary system to reach the desired location, which may be the kidneys or bladder.

- Navigating:

Navigating the complex urinary system is made possible by the design’s flexibility.

- Support:

Guidewires provide later equipment, such as ureteroscopes or catheters, stability and a course.

Urologic Guidewires: Essential Tools for Minimally Invasive Procedures

- Ureteroscopy:

They provide imaging and management of anomalies in the ureter (the tube that joins the kidney and bladder).

- Nephrostomy:

Direct kidney-to-pee channel created for a brief period of time.

- Urinary Stent Placement:

The ureter is kept open for urine flow by inserting a tiny tube.

Unveiling the Advantage: Hydrophilic Coating in Urologic Guidewires:

When wet, a hydrophilic coating—which means “water-loving”—makes a surface slick. This results in a number of significant advantages for urologic procedures:

- Smooth Passage:

The guidewire and the lining of the urinary system experience less friction thanks to the hydrophilic coating. In addition to improving patient comfort, this smoother route lowers the possibility of tissue injury.

- Reduced Trauma:

The hydrophilic coating protects the sensitive tissues of the urinary system by reducing friction, which may hasten the healing process.

- Enhanced Navigation:

The hydrophilic coating’s lubricity can make it simpler for the guidewire to navigate through instances with tight strictures or complicated anatomy, which would improve procedure efficiency.

What is a Urologic Hydrophilic Coated Guidewire OEM?

Medical device contract manufacturing to customer requirements is the specialty of an OEM. This translates to: in relation to urologic hydrophilic coated guidewires, OEMs are able to modify guidewire characteristics to meet your unique requirements. This entails adjusting the intended functions, length, diameter, and tip configuration.

- Labeling and branding:

By working with an OEM, you may create your own unique brand identification for the guidewires. You make sure your brand is clearly visible and maintain control over the labeling.

- Design Flexibility:

OEMs are able to meet any unique design specifications you may have. This might entail adding special features or modifying the guidewire’s characteristics to fit certain protocols.

Why people prefer Demax Urologic Hydrophilic Coated Guidewire OEM?

Demax has become a well-known urologic hydrophilic coated guidewire OEM that medical device manufacturers all around the globe rely on. Demax provides a complete solution to realize your idea thanks to their wealth of knowledge and dedication to personalization. You will obtain high-performance guidewires that are customized to meet your unique demands thanks to their focus on quality, dependability, and surpassing client expectations.

- Proven Track Record:

Demax has a track record and expertise in producing urologic hydrophilic coated guidewires of the highest caliber. Mention the number of years they have been in business or any notable accomplishments.

- Customization Proficiency:

Demax has the capacity to meet certain requirements. They have tailored guidewire attributes, such as length, diameter, tip configuration, and functions, to match the needs of their clients.

- Reliability and Quality:

Demax is dedicated to excellence. They have strict quality control methods, use premium products, and adhere to pertinent industry standards.

Advantages over competitors:

Demax offers special features like lower prices, quicker response times, or extra services like package customization or design assistance.

- Client-Side Focus:

Demax is committed to client happiness, emphasizing their technical support, responsiveness, and dedication to timely delivery.

Conclusion:

Partner with Demax, a leading Urologic Hydrophilic Coated Guidewire OEM. Experience, quality, and innovation ensure your success. We strictly follow the quality specifications and have established a medical device quality management system in accordance with ISO9001 and ISO13485 to ensure every stage of the production process. Our knowledgeable, multilingual sales staff and after-sales support system are able to react to client demands quickly.