In the realm of medical devices, the disposable urinary hydrophilic guidewire stands out as a crucial tool used in urological procedures. This innovative guidewire combines flexibility and hydrophilic properties to aid in the navigation of urinary tract anatomy, assisting physicians in performing complex procedures with precision and safety.

What is a Disposable Urinary Hydrophilic Guidewire?

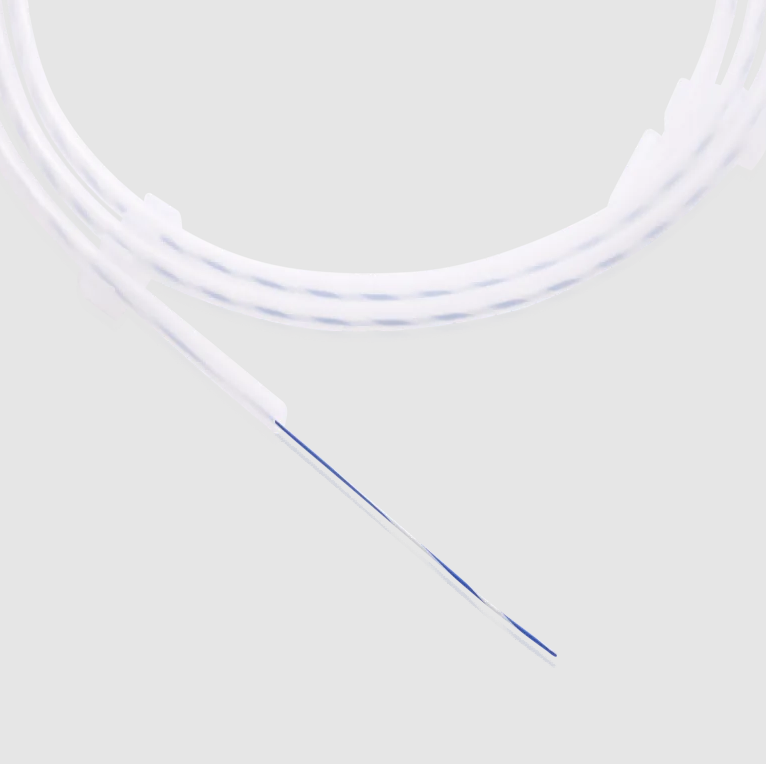

A disposable urinary hydrophilic guidewire is a slender, flexible wire used primarily in urology to access and navigate the urinary tract during diagnostic and therapeutic procedures. It is designed with a hydrophilic coating that becomes slippery when exposed to water or bodily fluids, facilitating smooth insertion and advancement through tortuous pathways within the urinary system. This feature reduces friction, minimizes trauma to delicate tissues, and enhances patient comfort during procedures.

Applications of Disposable Urinary Hydrophilic Guidewires

Diagnostic Procedures

Disposable urinary hydrophilic guidewires are indispensable in diagnostic cystoscopy and ureteroscopy procedures. They enable urologists to access the bladder and ureters safely, allowing for visual examination and biopsy of suspicious lesions or stones.

Therapeutic Interventions

During therapeutic interventions such as ureteral stenting or stone manipulation, these guidewires serve as a conduit for other instruments and devices. Their flexibility and hydrophilic nature aid in precise positioning and deployment of stents, baskets, or laser lithotripsy probes.

Minimally Invasive Surgery

In minimally invasive surgeries like percutaneous nephrolithotomy (PCNL) or transurethral resection of the prostate (TURP), these guidewires play a critical role in guiding the introduction of scopes and surgical instruments through narrow passages, ensuring minimal trauma to surrounding tissues.

Medical Market Status and Needs of Disposable Urinary Hydrophilic Guidewire

Increasing Prevalence of Urological Disorders

The global prevalence of urological conditions, such as kidney stones, urinary tract infections, and bladder cancers, continues to rise. This trend drives the demand for advanced medical devices like disposable urinary hydrophilic guidewires, which are essential for accurate diagnosis and effective treatment.

Shift Towards Minimally Invasive Procedures

Healthcare providers and patients alike increasingly favor minimally invasive procedures due to their reduced recovery times, lower risk of complications, and improved patient outcomes. Disposable urinary hydrophilic guidewires play a pivotal role in these procedures by enabling precise navigation through narrow and tortuous urinary tract anatomy.

Demand for Enhanced Safety and Efficiency

There is a growing emphasis on patient safety and procedural efficiency in urology. Disposable urinary hydrophilic guidewires are designed to minimize trauma to delicate tissues while ensuring accurate placement of catheters, stents, or other therapeutic instruments. This feature is crucial in optimizing clinical outcomes and reducing healthcare costs associated with prolonged hospital stays or post-operative complications.

Industrial Challenges in Disposable Urinary Hydrophilic Guidewire Manufacturing

Material Selection and Coating Technologies

Developing an effective hydrophilic coating that maintains its lubricity throughout the procedure without compromising biocompatibility or durability poses a significant challenge. Manufacturers like Demax invest heavily in research and development to optimize coating formulations and application methods.

Precision Manufacturing Processes

Achieving consistent quality and dimensional accuracy in the production of disposable urinary hydrophilic guidewires requires advanced manufacturing technologies. Challenges include maintaining tight tolerances in wire extrusion, coating application, and assembly processes to meet regulatory standards and ensure device performance.

Regulatory Compliance and Certification

Another layer of challenges facing manufacturers. Meet ISO standards for medical devices. It is necessary to establish strict quality management systems and detailed documentation throughout the entire manufacturing and distribution process.

OEM Solutions and Customization Options

Tailored Design and Development

OEM (Original Equipment Manufacturer) solutions offer healthcare providers the flexibility to customize disposable urinary hydrophilic guidewires to meet specific clinical needs. Demax works closely with OEM partners to develop custom solutions. Incorporating unique features or modifications to enhance the functionality and usability of the device.

Scalable Manufacturing Capabilities

Demax’s expertise in scalable manufacturing allows for efficient production of OEM solutions, whether in small batches for niche applications or large-scale manufacturing for global distribution. This flexibility ensures timely delivery and consistent quality across custom-designed guidewire products.

Regulatory Support and Documentation

Partnering with an experienced OEM manufacturer like Demax provides access to regulatory expertise and documentation support. From initial design verification to final product validation, Demax assists OEM partners in navigating regulatory requirements seamlessly, ensuring compliance and market readiness.

Future Trends in Disposable Urinary Hydrophilic Guidewire Technology

Advancements in Coating and Material Science

Future developments in coating technologies aim to enhance the lubricity and durability of disposable urinary hydrophilic guidewires. Innovations in biocompatible materials and surface treatments will further improve device performance and patient comfort during urological procedures.

Integration of Smart Technologies

The integration of smart technologies, such as sensors or navigational aids, holds promise for the future of disposable urinary hydrophilic guidewires. These advancements could enable real-time monitoring of device position or patient physiological parameters, enhancing procedural accuracy and safety.

Adoption of Sustainable Practices

As environmental sustainability becomes a priority in healthcare, manufacturers are exploring eco-friendly materials and manufacturing processes for disposable medical devices. Demax is committed to reducing environmental impact through responsible sourcing, recycling initiatives, and energy-efficient production practices.

Why Choose Demax as Your Disposable Urinary Hydrophilic Guidewire Manufacturer?

Technological Expertise and R&D Capabilities

Demax stands out in the medical device industry with its robust team of experts encompassing biology, material science, mechanics, and medicine. This interdisciplinary approach has fueled their innovative prowess, leading to the development of advanced R&D equipment and proprietary technologies. Their commitment to continuous improvement and technology innovation has earned them multiple patents, positioning them as leaders in the field.

State-of-the-Art Manufacturing Processes

Demax covers the entire production spectrum from automation to traditional methods, leveraging cutting-edge equipment and connectivity technologies. Their smart production lines enable real-time monitoring and data analytics, ensuring efficient and high-quality manufacturing. Compliance with stringent quality standards such as ISO9001 and ISO13485 underscores their dedication to producing reliable, sterile medical devices that meet global regulatory requirements.

Focus on Quality and Innovation

Quality assurance is paramount at Demax, with meticulous attention to detail at every stage of production. Advancements in coating, molding, welding, and testing technologies ensure that each guidewire meets the highest standards of performance and safety. They are committed to providing flawless products and customer satisfaction. And with an agile sales team and strong after-sales support system. Meet the diverse needs of healthcare professionals around the world.

Conclusion

In conclusion, the disposable urinary hydrophilic guidewire represents a pivotal advancement in urological instrumentation, enabling safer and more efficient procedures. Manufacturers like Demax do so through a commitment to innovation, quality and customer satisfaction. It reflects its leadership position and promotes the development of medical equipment towards higher precision and reliability. As healthcare continues to evolve. These guidewires will continue to be key in supporting clinicians in their quest for better patient care and outcomes.