The Demax PU Braided High-Pressure Tube utilizes polyurethane (PU), renowned for its exceptional mechanical properties and chemical resistance. Enhanced with a braided layer, the tubing exhibits superior strength and resilience against kinking and collapse. Compliant with rigorous medical industry standards, it guarantees biocompatibility and safety for patients by being free from latex, phthalates, and other harmful substances. Its versatility makes it indispensable across multiple sectors such as medical, automotive, and industrial applications, where it is valued for its reliability, flexibility, and durability under high-pressure environments.

Features of Demax PU Braided High-Pressure Tubes

Customizable Length

Demax PU Braided High-Pressure Tubes are available in customizable lengths, ensuring they meet precise medical procedure requirements. This flexibility enhances their versatility across various applications, allowing for tailored use in different healthcare settings.

High Pressure Resistance: Up to 1200 PSI

Engineered to withstand high-pressure environments, Demax PU Braided Tubes offer exceptional pressure resistance, up to 1200 PSI. This capability ensures reliable performance in demanding applications where precise fluid delivery under pressure is critical for patient safety and treatment efficacy.

Superior Flexibility

Featuring high flexibility, Demax PU Braided Tubes allow for easy manipulation during medical procedures. They can bend and twist without kinking, ensuring smooth fluid flow and optimal performance. This flexibility is crucial for intricate medical tasks that require precise handling and positioning.

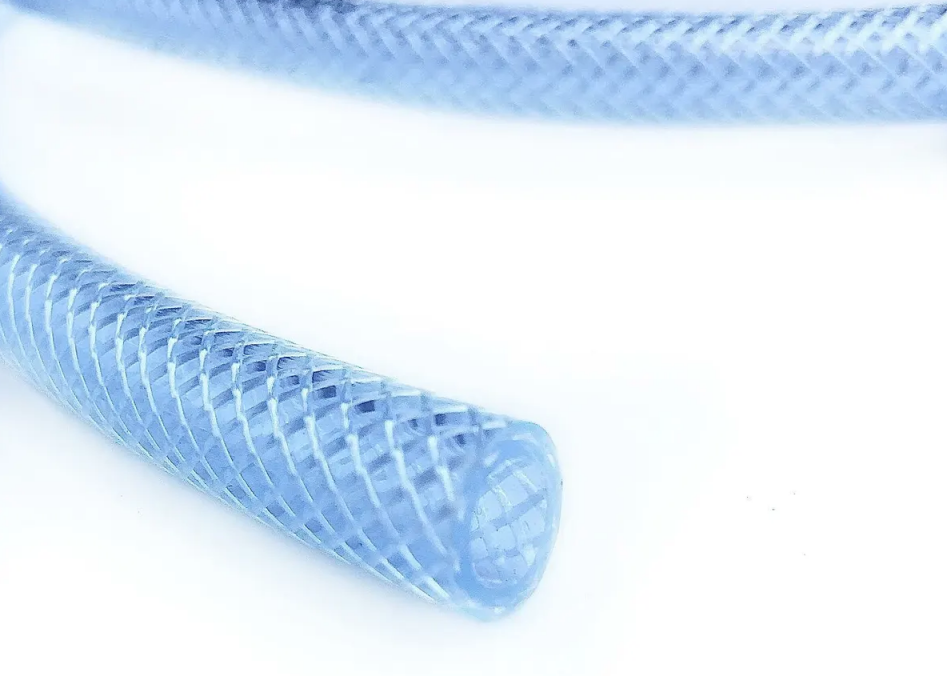

Reinforced with Braided Layer

These tubes are reinforced with a braided layer, providing enhanced strength and resistance to kinking and collapse. This structural reinforcement allows the tubing to maintain its shape and integrity even under high-pressure conditions, making it a dependable choice for critical medical applications.

Exceptional Durability

Demax PU Braided Tubes are engineered for durability, capable of withstanding the rigors of medical procedures without deformation. This durability ensures consistent and reliable performance throughout their use, contributing to the efficiency and safety of medical treatments.

Chemical Resistance

Highly resistant to chemicals and solvents used in medical settings, these tubes maintain compatibility with various fluids and medications. This chemical resistance minimizes the risk of fluid degradation or contamination, preserving the purity and effectiveness of transported substances.

Smooth Inner Surface

Featuring a smooth inner surface, Demax PU Braided Tubes facilitate optimal fluid flow with reduced friction and turbulence. This smooth flow characteristics ensure efficient fluid delivery during medical procedures, essential for maintaining patient safety and treatment efficacy.

Applications in Medical Fields

Intravenous Therapy

Demax PU Braided Tubes are essential for intravenous (IV) therapy, enabling the reliable delivery of fluids, medications, and blood products. Their flexibility and smooth inner surface support efficient fluid administration critical for patient care.

Enteral Feeding

Used in enteral feeding procedures, these tubes deliver nutrition solutions and medications safely and effectively. Their chemical resistance ensures compatibility with various feeding solutions, maintaining nutritional integrity and patient safety.

Endoscopy

In endoscopic procedures like gastroscopy and colonoscopy, Demax PU Braided Tubes are employed for irrigation, suction, and insufflation. Their durability and high-pressure resistance make them suitable for these demanding applications in gastrointestinal diagnostics and treatments.

Respiratory Therapy

For respiratory therapy procedures, these tubes deliver oxygen and respiratory gases efficiently. Their flexibility and smooth inner surface facilitate optimal gas delivery, crucial for treatments such as mechanical ventilation and oxygen therapy.

Urology Procedures

During urological procedures such as cystoscopy and ureteroscopy, Demax PU Braided Tubes deliver irrigation fluids and contrast media reliably. Their robust construction and chemical resistance ensure precise fluid management, supporting effective diagnostic and therapeutic interventions in urology.

Performance and Safety Considerations

Standards Compliance

Demax PU Braided High-Pressure Tubes adhere rigorously to regulatory requirements, including FDA and ISO standards. These standards ensure the tubing meets the highest safety and performance levels, essential for critical medical applications. Compliance guarantees the tubing’s safety for patient use and reliability under diverse conditions.

Testing and Quality Assurance

Demax PU Braided Tubes undergo comprehensive testing and quality assurance procedures to ensure reliability and safety. Methods such as pressure testing, chemical resistance testing, and durability assessments confirm consistent performance under stress. This stringent testing regimen maintains superior product quality, ensuring each tube meets required specifications before market release.

Longevity and Maintenance

Designed for durability, Demax PU Braided Tubes have a lifespan that matches the demands of medical procedures. Regular maintenance, including inspections for wear and adherence to usage guidelines, prolongs tube lifespan. Proper storage and cleaning according to manufacturer instructions preserve tubing integrity and performance over time.

Future Trends and Innovations

Advancements in Material Technology

The future of PU braided high-pressure tubes hinges on material technology advancements. Emerging materials like enhanced polymers and composites promise improved tube performance and durability. These innovations may lead to tubes more resistant to chemicals, pressure, and wear, broadening applications and enhancing patient safety.

Integration with Smart Technologies

Smart technologies integration, such as IoT applications and monitoring systems, is a burgeoning trend in medical tubing. Sensor-equipped smart tubes deliver real-time data on fluid flow, pressure, and critical parameters. This integration enhances procedural monitoring and management, improving patient outcomes and operational efficiency.

Sustainability Initiatives

Sustainability is increasingly pivotal in medical manufacturing. Development of eco-friendly materials and sustainable production processes aims to reduce medical product environmental impact. Demax embraces these initiatives, striving to create environmentally responsible, high-performance tubes. This sustainability focus meets rising demand for green medical products, benefiting both environmental health and market preference.

Summary

The Demax PU Braided High-Pressure Tube sets a benchmark for innovation and reliability in medical tubing, harnessing polyurethane for its superior mechanical properties and chemical resistance. Enhanced with a braided layer, it ensures outstanding strength and resilience against kinking and collapse, making it an ideal choice for critical applications. Meeting rigorous medical standards guarantees patient safety and biocompatibility, with the tubing free from harmful substances such as latex and phthalates. Its versatility spans across medical, automotive, and industrial sectors, valued for its durability and flexibility under high-pressure conditions. Demax PU Braided Tubes offer a dependable solution for high-performance fluid delivery, enhancing the safety and efficiency of medical procedures.