Catheter shafts play a pivotal role in medical devices, facilitating precise and efficient delivery of fluids or instruments within the body. PU (Polyurethane) braided catheter shafts are particularly renowned for their exceptional performance and dependability. Constructed from high-performance polyurethane, the Demax braided catheter shaft boasts superior mechanical properties and chemical resistance. Its reinforced braided layer enhances durability, preventing kinking and collapse during use. This catheter shaft adheres to rigorous medical industry standards, ensuring biocompatibility and patient safety by being free from latex, phthalates, and other harmful substances, thereby minimizing the risk of adverse reactions.

Understanding PU Braided Catheter Shafts

Definition and Composition of PU Braided Catheter Shafts

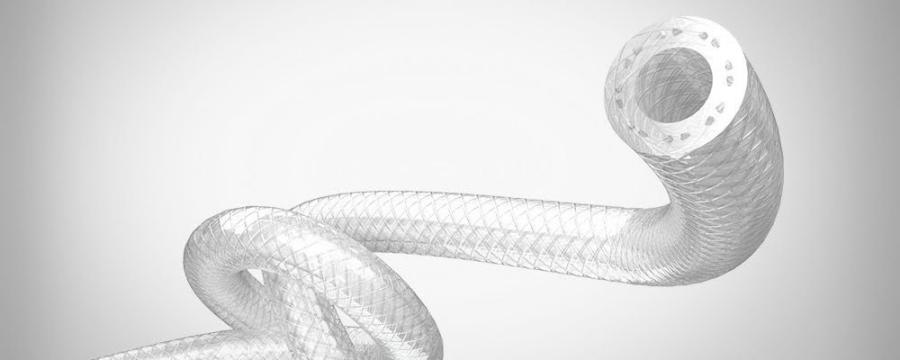

PU braided catheter shafts are advanced medical components designed for delivering fluids or instruments within the body. Composed of polyurethane (PU), a high-performance polymer known for its exceptional mechanical properties, these shafts feature a reinforced structure with a braided layer. This design provides added strength and resistance to external pressures, ensuring the catheter shaft maintains integrity and functionality during medical procedures.

Benefits of PU Material in Medical Applications

The use of PU material in catheter shafts offers significant advantages in medical settings. PU’s high flexibility allows for easy manipulation and positioning within the body, crucial for navigating complex pathways without kinking or obstructing fluid flow. Its durability ensures the catheter withstands the demands of medical procedures without deformation. Moreover, PU’s biocompatibility ensures safe interaction with bodily tissues and fluids, minimizing the risk of adverse reactions and supporting successful medical treatments.

Comparison with Other Materials Used in Catheter Shafts

When compared to alternatives like PVC and nylon, PU braided catheter shafts demonstrate superior performance. PVC, although flexible, lacks durability and can become brittle over time, compromising longevity and safety. Nylon offers strength but is less flexible than PU, potentially hindering maneuverability during procedures. PU strikes a balance between flexibility and strength, making it ideal for catheter shaft applications. Additionally, PU’s superior biocompatibility compared to PVC, which can release harmful substances, underscores its suitability for medical use.

Demax Braided Catheter Shaft

Customizable Length and Pressure Resistance

The Demax braided catheter shaft is tailored to meet specific medical requirements with customizable length options and robust pressure resistance of up to 1200 PSI. This capability ensures the catheter maintains integrity during fluid delivery and instrument insertion, crucial for reliable performance in diverse medical procedures.

High Flexibility

Featuring PU braided tubing, the Demax catheter shaft offers exceptional flexibility, facilitating easy manipulation and precise positioning during medical interventions. Its ability to bend and twist without kinking ensures smooth fluid flow and optimal performance, enhancing control and efficiency for healthcare professionals.

Braided Reinforcement

Reinforced with a braided layer, the Demax catheter shaft delivers enhanced strength and resilience against kinking and collapse. This reinforcement maintains the shaft’s shape and structural integrity, even under high-pressure conditions, ensuring continuous functionality throughout medical procedures.

Excellent Durability

Engineered for durability, the PU braided tubing of the Demax catheter shaft exhibits resilience and resistance to deformation under rigorous medical conditions. It retains structural integrity, ensuring reliable performance throughout procedures, thereby supporting safe and effective use over extended periods.

Chemical Resistance

The Demax catheter shaft boasts high chemical resistance, safeguarding against degradation and contamination from common medical solvents and fluids. This resistance preserves the purity of transported fluids, enhancing safety and efficacy in medical treatments while minimizing risks associated with material interactions.

Smooth Inner Surface

With a smooth inner surface, the Demax catheter shaft optimizes fluid flow efficiency, reducing the risk of obstruction and turbulence during medical procedures. This streamlined design supports seamless delivery of fluids, contributing to overall performance reliability and making it a preferred choice for medical professionals.

Key Performance Advantages

Enhanced Flexibility and Kink Resistance for Improved Navigation Through Vessels

PU braided catheter shafts excel in flexibility and kink resistance, crucial for navigating intricate vascular pathways. This design allows smooth maneuverability during procedures, minimizing blockages and ensuring optimal fluid flow. Their ability to bend and twist without compromising integrity enhances procedural accuracy and efficiency, making them essential tools for medical professionals.

Strength and Durability to Withstand Repetitive Use and External Pressures

PU braided catheter shafts are engineered for durability, capable of withstanding repetitive use and external pressures encountered in medical settings. The braided reinforcement provides robust support, maintaining shape and functionality under high-stress conditions. This durability translates to extended performance life and reduced risk of catheter failure, ensuring safety and efficacy during procedures.

Biocompatibility Features that Minimize Risk of Patient Reactions or Infections

Biocompatibility is a hallmark of PU braided catheter shafts, minimizing the risk of adverse reactions and infections in patients. Their compatibility with bodily tissues and fluids ensures safe usage without triggering immune responses or irritation. This feature is pivotal in enhancing patient outcomes by reducing complications, making PU braided catheter shafts preferred in various medical applications.

Applications in Medical Devices

Specific Medical Applications Where PU Braided Catheter Shafts Are Utilized

PU braided catheter shafts find versatile applications across medical fields. In cardiovascular procedures, they facilitate the precise delivery of fluids and instruments within blood vessels. In urology, they aid in irrigation and contrast media delivery during procedures like cystoscopy and ureteroscopy. In neurology, these catheters navigate delicate brain structures for diagnostic and therapeutic purposes. They are also vital in intravenous therapy, enteral feeding, endoscopy, and respiratory therapy, ensuring efficient treatment delivery in diverse medical scenarios.

Examples Highlighting Successful Implementations

Numerous case studies underscore the successful deployment of PU braided catheter shafts in medical procedures. For instance, in cardiovascular interventions, these catheters enable smooth navigation through complex arterial pathways, reducing procedural time and complications. In urological procedures, PU braided catheters ensure reliable delivery of irrigation solutions and contrast agents, enhancing procedure accuracy and patient safety. Such examples highlight the reliability and effectiveness of PU braided catheter shafts in critical medical applications.

Future Trends and Innovations

Emerging Technologies and Materials in Catheter Shaft Design

The future of catheter shafts is promising with advancements in materials like advanced polymer composites and nanotechnology. These innovations aim to enhance mechanical properties and functionality, creating catheters that are more flexible, durable, and biocompatible. Such developments cater to evolving medical needs, ensuring safer and more effective procedures.

Potential Improvements in Performance and Patient Outcomes

Future advancements in PU braided catheter shafts promise significant improvements in performance and patient outcomes. Enhanced materials and designs will offer greater flexibility, strength, and resistance to external pressures, enhancing reliability during medical procedures. Improved biocompatibility will further mitigate risks of patient reactions and infections, promoting safer and more successful treatments.

Predictions for the Future of PU Braided Catheter Shafts in Medical Device Innovation

Looking ahead, PU braided catheter shafts are poised to drive innovations in medical devices. Future designs may incorporate smart features such as real-time monitoring sensors, enhancing procedural precision and patient care. With ongoing research and development, these catheter shafts will continue to evolve, becoming indispensable tools across various medical specialties. The future holds promising possibilities for PU braided catheter shafts, advancing healthcare with advanced technologies and enhanced capabilities.

Closing Words

Catheter shafts are essential components of medical devices, facilitating precise and efficient delivery of fluids and instruments within the body. PU (Polyurethane) braided catheter shafts are highly regarded for their exceptional performance and reliability in this role. The Demax braided catheter shaft, crafted from high-performance polyurethane, boasts superior mechanical properties and chemical resistance. Its reinforced braided layer ensures durability, preventing kinking and collapse during procedures. Meeting stringent medical industry standards, this catheter shaft prioritizes biocompatibility and patient safety by eliminating latex, phthalates, and other harmful substances, thereby minimizing the risk of adverse reactions. As medical technology progresses, PU braided catheter shafts will remain indispensable, contributing to improved procedural precision, enhanced patient outcomes, and ongoing advancements in healthcare innovation.