Medical guidewires play a critical role in minimally invasive procedures by facilitating the navigation of catheters and other devices through the complex vascular system of the body. These thin, flexible wires are indispensable for precise interventions like angioplasty and stenting. Hydrophilic nitinol guidewires, a specialized variant, are particularly esteemed for their distinct characteristics. Their hydrophilic coating attracts and holds water, resulting in a slick and smooth surface that decreases friction. This property enables the guidewire to navigate smoothly through narrow and tortuous blood vessels, thereby reducing the potential for vessel wall damage and improving the overall safety and effectiveness of medical procedures.

Understanding Nitinol

Definition and Properties of Nitinol

Nitinol, a Nickel-Titanium alloy, is known for its exceptional elasticity and shape memory properties. These characteristics allow it to return to its original shape after deformation, making it highly suitable for applications requiring precision and resilience. Nitinol exhibits excellent biocompatibility, essential for medical devices that interact with bodily tissues.

Why Nitinol is Ideal for Medical Applications, Especially Guidewires

Nitinol’s unique properties make it an ideal material for medical guidewires. Its flexibility allows guidewires to navigate through the body’s intricate vascular system without causing damage. The shape memory effect ensures that the guidewire maintains its form and functionality even under the stress of complex procedures. Additionally, Nitinol’s biocompatibility minimizes the risk of adverse reactions within the body.

Historical Context of Nitinol’s Development and Medical Usage

Nitinol was first discovered in the early 1960s by researchers at the Naval Ordnance Laboratory, hence its name derived from Nickel Titanium Naval Ordnance Laboratory. Its application in medicine began in the 1970s, revolutionizing the field of minimally invasive surgery. Over the decades, Nitinol has become a cornerstone in the development of various medical devices, particularly guidewires, due to its reliability and performance.

The Concept of Hydrophilicity

Explanation of Hydrophilicity in Medical Devices

Hydrophilicity refers to a material’s ability to attract and hold water molecules on its surface. In medical devices, hydrophilic coatings create a water-friendly layer that significantly reduces friction. This property is crucial for devices that need to maneuver smoothly within the body, such as guidewires and catheters.

Importance of Hydrophilic Coatings on Guidewires

The hydrophilic coating on guidewires is essential for ensuring ease of movement through the vascular system. This slippery surface minimizes resistance, allowing the guidewire to traverse complex and narrow pathways with minimal force. The reduced friction not only enhances the precision of the procedure but also lowers the risk of damaging delicate vessel walls.

Benefits of Hydrophilic Surfaces in Navigating Through Vasculature

Hydrophilic surfaces provide significant advantages in vascular navigation. They enable guidewires to glide effortlessly through tortuous and challenging pathways, improving procedural efficiency and safety. The reduction in friction ensures smoother insertion and manipulation, leading to better outcomes and shorter procedure times. Additionally, hydrophilic guidewires reduce the likelihood of vessel trauma, making them a preferred choice in delicate and critical interventions.

Design and Construction of Demax Hydrophilic Nitinol Guidewires

Structure of Hydrophilic Nitinol Guidewires

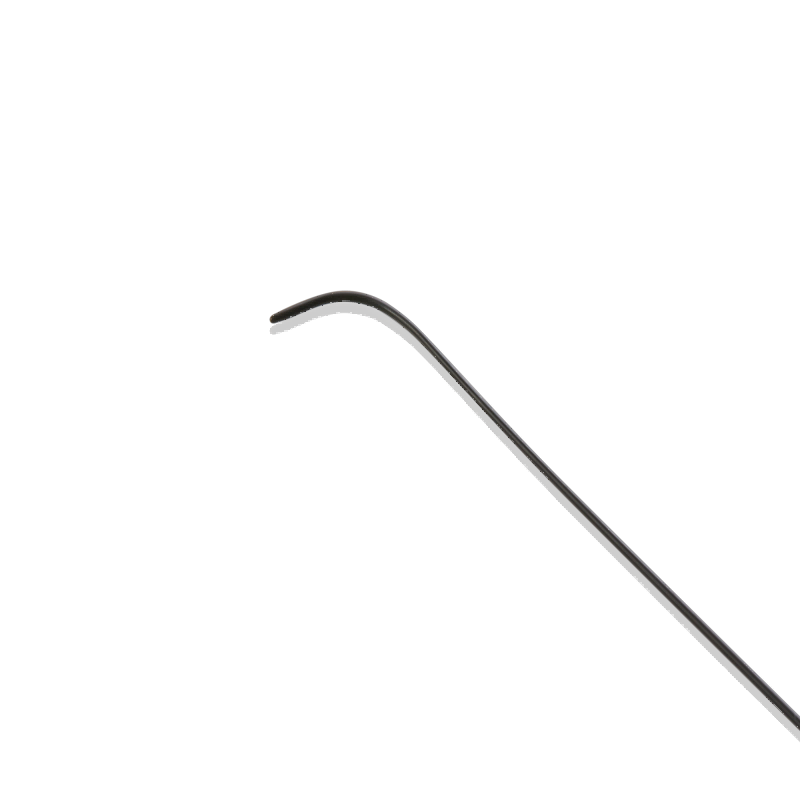

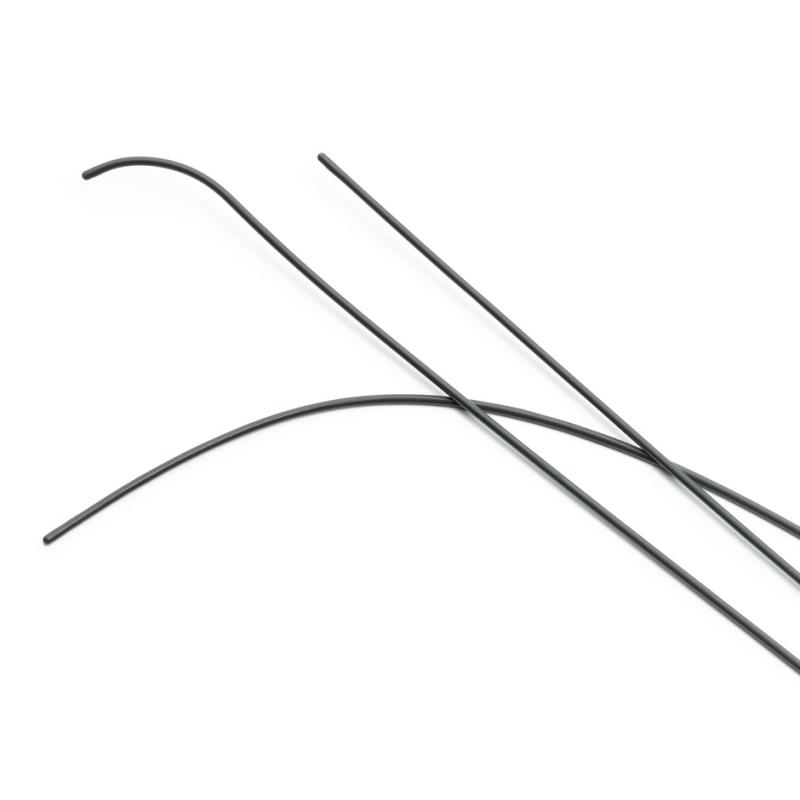

Hydrophilic nitinol guidewires are composed of a core material, typically stainless steel or nitinol, encased in a hydrophilic polymer coating. Stainless steel provides the essential rigidity and structural integrity necessary to withstand the forces encountered during navigation. Nitinol, known for its shape-memory properties, offers flexibility and elasticity, allowing the guidewire to conform to anatomical contours without compromising durability. The hydrophilic coating, often made of materials like PTFE, serves as a lubricious layer that minimizes friction and facilitates smooth navigation through bodily passages. This coating undergoes meticulous manufacturing processes to ensure uniformity and durability, maintaining optimal hydrophilic properties throughout medical procedures.

Role of Nitinol Core and Hydrophilic Coating

Nitinol plays a pivotal role in the guidewire’s core, providing the necessary flexibility and elasticity to navigate complex anatomical structures with ease. The hydrophilic coating on the outer layer enhances the guidewire’s performance by reducing friction, ensuring seamless passage through the vasculature. This dual-layer construction—combining a flexible core with a slick outer surface—creates a guidewire that is highly adaptable and maneuverable, thereby minimizing the risk of vessel damage and optimizing procedural efficiency.

Manufacturing Processes for Hydrophilic Nitinol Guidewires

The manufacturing of hydrophilic nitinol guidewires involves advanced processes to achieve superior performance. The hydrophilic coating is designed to activate rapidly upon contact with bodily fluids, enabling effortless advancement through vessels while mitigating friction. Guidewires are meticulously crafted to strike a balance between flexibility and support, facilitating exceptional maneuverability during procedures. A radiopaque marker at the distal end ensures excellent visibility under fluoroscopy, crucial for precise positioning. Available in various lengths, these guidewires are tailored to accommodate diverse procedural requirements. The tapered tip design promotes smooth entry into vessels, reducing trauma to delicate tissues and enhancing overall patient safety.

Applications in Medical Procedures

Common Medical Procedures Utilizing Hydrophilic Nitinol Guidewires

Hydrophilic nitinol guidewires are indispensable across multiple medical specialties:

- Cardiology: Facilitating the placement of stents, balloons, and catheters during angioplasty and other cardiac interventions.

- Interventional Radiology: Guiding catheters for embolization, biopsy procedures, and fluid collection drainage.

- Urology: Assisting in the placement of ureteral stents and accessing the urinary tract for diagnostic and therapeutic purposes.

- Gastroenterology: Navigating through biliary and pancreatic ducts for ERCP (Endoscopic Retrograde Cholangiopancreatography) and stent placement procedures.

Advantages Over Traditional Guidewires in Medical Scenarios

Hydrophilic nitinol guidewires offer significant advantages over traditional guidewires, especially in navigating tortuous anatomy and negotiating tight lesions. The hydrophilic coating reduces friction, allowing smoother passage through narrow and winding vessels, thereby decreasing the risk of vessel damage and enhancing procedural safety. Moreover, the flexibility of the nitinol core enhances maneuverability, facilitating easier navigation through complex vascular structures and improving overall procedural outcomes.

Clinical Benefits and Outcomes

Clinical Studies Supporting Hydrophilic Nitinol Guidewires

Extensive clinical studies validate the efficacy of hydrophilic nitinol guidewires, demonstrating significant improvements in procedural success rates and complication reduction. The enhanced maneuverability and reduced friction contribute to safer and more efficient procedures, particularly in challenging clinical scenarios.

Patient Outcomes and Procedural Success

The adoption of hydrophilic nitinol guidewires has resulted in improved patient outcomes and higher procedural success rates. Patients experience fewer complications, and procedures are completed more swiftly and accurately. These guidewires’ advanced navigation capabilities translate to better clinical outcomes, shorter recovery times, and enhanced patient satisfaction.

Testimonials

Healthcare professionals endorse hydrophilic nitinol guidewires through testimonials and case studies, highlighting their successful applications in diverse medical interventions. Physicians attest to improved procedural efficiency and patient safety attributed to the advanced design and construction of these guidewires. Real-world examples underscore their pivotal role in modern medical practice, reinforcing their value across various specialties.

In Closing

Medical guidewires are essential instruments for navigating catheters and other devices through the intricate vascular system during minimally invasive procedures. They play a critical role in interventions like angioplasty and stenting, where precision is paramount. Hydrophilic nitinol guidewires, known for their specialized properties, are highly valued in medical practice. Their hydrophilic coating, which attracts and retains water, ensures a smooth, low-friction surface. This characteristic allows the guidewire to maneuver effortlessly through narrow and winding blood vessels, thereby reducing the risk of vessel wall damage and enhancing procedural safety. With their advanced design, unique material characteristics, and documented clinical advantages, hydrophilic nitinol guidewires are indispensable tools that significantly contribute to improved patient outcomes and the success of medical procedures.