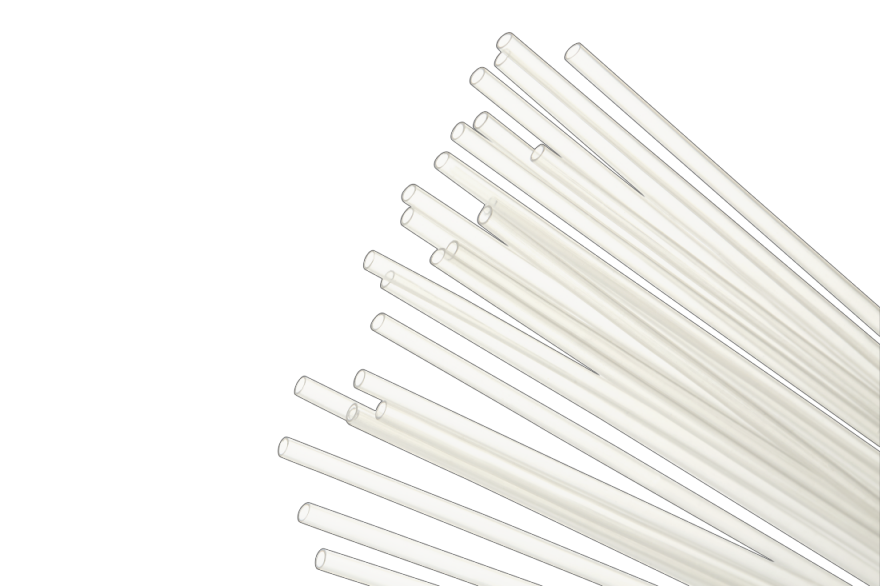

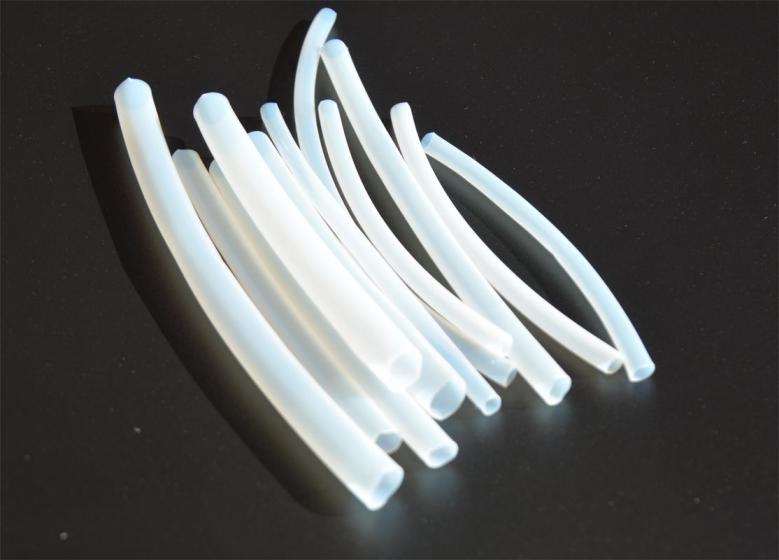

Heat shrink tubing is indispensable in industry for insulating, protecting, and organizing wires and cables. Polytetrafluoroethylene (PTFE) heat shrink tubing stands out among its peers for its remarkable chemical resistance, ability to withstand high temperatures, and non-stick properties. In the rapidly advancing field of medical technology, precise and reliable fluid delivery is crucial. Introducing the PTFE Heat Shrink Tube, crafted from fluorinated ethylene propylene (PTFE). This tubing innovation transforms medical procedures by providing a smooth conduit for fluid transfer and medical instruments, characterized by outstanding clarity, flexibility, and biocompatibility.

Understanding Polytetrafluoroethylene (PTFE) Heat Shrink Tube

Definition and Composition of PTFE

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer renowned for its unique properties and versatile applications. Composed primarily of carbon and fluorine atoms, PTFE is chemically inert and resistant to various environmental factors. PTFE heat shrink tubing is created by extruding and expanding PTFE material, which then shrinks when heated, conforming tightly around objects to provide insulation and protection.

Properties and Advantages

- High Thermal Stability

PTFE heat shrink tubing exhibits remarkable thermal stability, capable of withstanding extreme temperatures ranging from -200°C to +260°C. This high-temperature endurance makes it ideal for use in demanding industrial and medical environments where temperature fluctuations are common.

- Chemical Resistance

One of PTFE’s most significant advantages is its exceptional resistance to chemicals, including acids, bases, and solvents. This resistance ensures that PTFE heat shrink tubing maintains its integrity and performance even when exposed to harsh chemical environments, making it suitable for various industrial and medical applications.

- Non-stick Surface

PTFE is well-known for its non-stick properties, which prevent substances from adhering to its surface. This non-stick characteristic is particularly beneficial in medical applications, as it minimizes the risk of contamination and ensures smooth fluid flow through the tubing. The non-stick surface also facilitates easy cleaning and maintenance.

Applications of PTFE Heat Shrink Tube

Intravenous Therapy

PTFE heat shrink tubing is employed in intravenous therapy to administer fluids, medications, and contrast agents in hospital settings. Its biocompatibility and non-stick properties ensure accurate and reliable delivery with minimal risk of contamination. The tubing’s clarity allows healthcare professionals to monitor the flow of fluids, ensuring precise administration.

Surgical Procedures

In surgical procedures, PTFE heat shrink tubing is utilized for the controlled delivery of irrigation solutions, hemostatic agents, or contrast media. This tubing enables surgeons to maintain clear visibility and precise control throughout the procedure, enhancing the effectiveness and safety of surgical interventions. Its flexibility and biocompatibility make it a valuable tool in the operating room.

Endoscopic Examinations

PTFE heat shrink tubing is integrated into endoscopic devices used for gastrointestinal or urological examinations. The tubing provides a clear conduit for the insertion of endoscopes and auxiliary instruments while facilitating fluid irrigation and suction. Its chemical resistance and non-stick properties ensure optimal performance during endoscopic procedures, enhancing diagnostic accuracy and patient safety.

Diagnostic Imaging

In diagnostic imaging, PTFE heat shrink tubing is incorporated into medical imaging systems such as angiography, fluoroscopy, or computed tomography (CT) scans. The tubing enables the administration of contrast agents with optimal flow rates and minimal risk of leakage or occlusion. Its clarity and biocompatibility ensure accurate imaging results, contributing to effective diagnosis and treatment planning.

Key Features of Demax PTFE Heat Shrink Tube

Customizable Outer Diameter (OD)

Demax offers PTFE Heat Shrink Tubes with customizable outer diameters ranging from 1.5mm to 6.0mm, tailored to specific procedural requirements and medical devices. This flexibility ensures seamless integration within diverse clinical settings, enhancing the precision and functionality of medical instruments.

Tailored Length

Demax provides tailored lengths for the PTFE Single Lumen Tube, accommodating various medical applications. Customizable lengths allow healthcare providers to achieve a perfect fit, optimizing the efficiency and effectiveness of medical procedures across different clinical scenarios.

Precision Inner Diameter (ID)

The inner diameter (ID) of Demax’s PTFE Heat Shrink Tube ranges from 0.5mm to 5.0mm, meticulously controlled to ensure precise fluid delivery and instrument insertion. This versatility meets the demands of different procedural requirements, ensuring reliable performance in critical medical situations.

Strict Tolerance Control

Demax maintains an inner diameter tolerance of ±0.05mm for the PTFE Single Lumen Tube, ensuring consistency and accuracy in tubing dimensions. This stringent tolerance minimizes deviations, preserving the reliability and performance of the tubing during crucial medical procedures.

Trust in Demax

Demax’s reputation for excellence, reliability, and customer satisfaction is underscored by their commitment to quality and innovation. With a proven track record in delivering high-quality products and exceptional service, Demax stands as a trusted partner in the medical industry. Their dedication to transparency, communication, and exceeding customer expectations ensures that every product meets the highest standards of performance and reliability.

Considerations for Choosing PTFE Heat Shrink Tube

Temperature Range Requirements

Consider the specific temperature conditions of your application when selecting a PTFE heat shrink tube. PTFE tubing offers high thermal stability, but ensuring compatibility with your procedure’s temperature range is crucial for optimal safety and performance.

Chemical Resistance

Evaluate the potential chemical exposure the tubing will encounter. PTFE is highly resistant to chemicals, but understanding the types and concentrations of chemicals involved ensures longevity and integrity in your application. This consideration is essential for maintaining the tubing’s performance and reliability over time.

Size and Shrink Ratio

Choosing the correct size and shrink ratio is critical for the effectiveness of PTFE heat shrink tubing. The tubing should snugly fit around components to provide adequate protection or insulation. Carefully assessing the required shrink ratio ensures a secure and precise fit, enhancing the tubing’s functionality across various medical and industrial applications.

Closing Words

Heat shrink tubing is indispensable in industry for insulating, protecting, and organizing wires and cables. Among various options, Polytetrafluoroethylene (PTFE) heat shrink tubing stands out for its remarkable chemical resistance, high-temperature endurance, and non-stick properties. In the rapidly advancing field of medical technology, precise and reliable fluid delivery is crucial. The introduction of the PTFE Heat Shrink Tube, crafted from fluorinated ethylene propylene (PTFE), has transformed medical procedures. This tubing provides a smooth conduit for fluid transfer and medical instruments, characterized by outstanding clarity, flexibility, and biocompatibility. Demax’s customizable outer diameter, tailored lengths, precision inner diameter, and strict tolerance control ensure optimal performance. Trust in Demax is reinforced by their commitment to quality, innovation, and customer satisfaction. When selecting PTFE heat shrink tubing, consider temperature range requirements, chemical resistance, and size and shrink ratio to ensure effective and reliable application.