Polyolefin Heat Shrink Tubes have become indispensable in various industries due to their versatility and efficiency. This blog will delve into what Polyolefin Heat Shrink Tubes are, their applications, their crucial role in different sectors, and how businesses can OEM or ODM their Polyolefin Heat Shrink Tube products to meet specific needs.

What is Polyolefin Heat Shrink Tube?

Definition and Composition

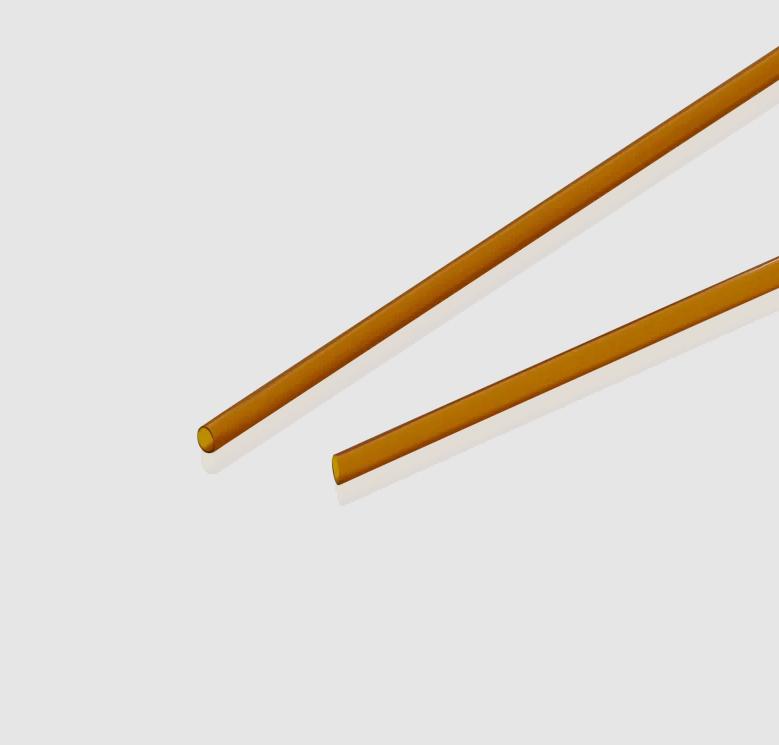

Polyolefin Heat Shrink Tube is a type of plastic tubing that shrinks in diameter when heated. Made from polyolefin, a polymer produced from the polymerization of olefins, these tubes are known for their superior insulation properties, resistance to chemicals, and durability. The material’s molecular structure allows it to return to its original shape after shrinking, providing a snug and protective covering.

Characteristics and Properties

Polyolefin Heat Shrink Tubes are favored for their excellent electrical insulation, high temperature resistance, and flame retardant properties. They also offer good mechanical strength, making them ideal for protecting cables, wires, and other components from environmental damage and physical abrasion. Available in various sizes, colors, and shrink ratios, these tubes can cater to diverse requirements across different applications.

Advantages over Other Materials

Compared to other heat shrink materials, polyolefin stands out for its balance of properties. It combines flexibility and strength, ensuring long-lasting performance in harsh conditions. Additionally, polyolefin heat shrink tubes do not produce harmful byproducts when heated, making them safer and more environmentally friendly.

Applications of Polyolefin Heat Shrink Tube

Electrical and Electronics Industry

Polyolefin Heat Shrink Tubes are extensively used in the electrical and electronics industry for insulating wires, terminals, and connections. They provide excellent protection against electrical faults, moisture, and dust. In electronics, these tubes are used for bundling cables, color-coding wires, and offering strain relief, ensuring that connections remain secure and reliable.

Medical and Healthcare Sector

In the medical and healthcare sector, Polyolefin Heat Shrink Tubes play a vital role in protecting sensitive equipment and components. They are used in medical device manufacturing to insulate and protect wiring in diagnostic and therapeutic equipment. The biocompatibility and sterilizability of polyolefin make it suitable for medical applications, ensuring that devices remain safe and effective during use.

Automotive and Aerospace Industry

The automotive and aerospace industries benefit greatly from Polyolefin Heat Shrink Tubes due to their ability to withstand extreme temperatures and environmental conditions. In these sectors, the tubes are used to protect electrical systems, harnesses, and components from heat, chemicals, and physical damage. This ensures the longevity and reliability of vehicles and aircraft, contributing to overall safety and performance.

The Rising Demand for Polyolefin Heat Shrink Tubes

Increasing Technological Advancements

The rapid advancements in technology across industries have created a surge in the demand for high-quality insulation materials. Polyolefin Heat Shrink Tubes, with their superior properties, have become the go-to solution for many applications. As industries continue to innovate, the need for reliable and adaptable materials like Polyolefin Heat Shrink Tubes is expected to grow.

Enhanced Safety and Compliance Standards

With stricter safety and compliance standards being implemented globally, industries are turning to Polyolefin Heat Shrink Tubes to meet these requirements. These tubes offer excellent electrical insulation, chemical resistance, and flame retardant properties, making them essential for maintaining safety and compliance. This trend is particularly evident in sectors such as medical healthcare, where safety is paramount.

Growing Focus on Sustainability

As sustainability becomes a critical concern, industries are seeking eco-friendly solutions. Polyolefin Heat Shrink Tubes are gaining popularity due to their minimal environmental impact and non-toxic properties. Their ability to provide durable protection while being environmentally friendly aligns with the global shift towards greener practices.

The Important Role of Polyolefin Heat Shrink Tube

Enhancing Safety and Reliability

One of the most critical roles of Polyolefin Heat Shrink Tubes is enhancing safety and reliability. By providing robust insulation and protection, these tubes prevent electrical short circuits, reduce the risk of fires, and safeguard components from environmental hazards. This is particularly important in industries where safety and reliability are paramount, such as medical devices and aerospace.

Extending Product Lifespan

Polyolefin Heat Shrink Tubes also contribute to extending the lifespan of products. By protecting wires and components from wear and tear, these tubes ensure that devices and systems remain operational for longer periods. This is especially valuable in the automotive and electronics industries, where the longevity of components directly impacts performance and maintenance costs.

Cost-Effective Solutions

Using Polyolefin Heat Shrink Tubes is a cost-effective solution for many applications. They are relatively inexpensive compared to other protective measures, yet they offer high durability and efficiency. This makes them an attractive option for manufacturers and suppliers looking to improve product quality without significantly increasing costs.

How to OEM or ODM Your Polyolefin Heat Shrink Tube Product for Your Business Needs

Understanding OEM and ODM

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) are two strategies businesses can use to customize Polyolefin Heat Shrink Tubes for their specific needs. OEM involves manufacturing products based on the buyer’s specifications, while ODM involves designing and producing products that the buyer can rebrand and sell.

Steps to OEM/ODM Your Product

Identify Requirements: The first step in OEM or ODM is to identify the specific requirements of your Polyolefin Heat Shrink Tube product. This includes size, color, shrink ratio, and any special properties needed for your application.

Partner with a Reliable Manufacturer: Choose a reliable manufacturer like Tianjin Demax Medical Technology Co., Ltd., known for their expertise and quality products. Discuss your requirements in detail to ensure they understand your needs.

Design and Prototyping: Work with the manufacturer to design and prototype the product. This stage may involve several iterations to refine the product and ensure it meets your specifications.

Ensuring Quality and Compliance

When OEM or ODMing Polyolefin Heat Shrink Tubes, it is crucial to ensure quality and compliance with relevant standards. This involves rigorous testing and quality control measures to verify that the products meet industry standards and perform as expected in their intended applications. Compliance with standards such as ISO, RoHS, and UL is often required, especially in industries like healthcare and automotive.

Marketing and Distribution

Once the customized Polyolefin Heat Shrink Tube products are ready, the next step is marketing and distribution. Highlight the unique features and benefits of your customized products to attract dealers and suppliers. Emphasize aspects such as improved safety, durability, and cost-effectiveness to appeal to potential customers.

Conclusion

Polyolefin Heat Shrink Tubes are an essential component in various industries, offering protection, insulation, and durability. Their applications range from electrical insulation to medical device protection, making them a versatile solution for many challenges. By understanding the process of OEM and ODM, businesses can customize these tubes to meet specific needs, ensuring high-quality and reliable products. Partnering with a reputable manufacturer like Tianjin Demax Medical Technology Co., Ltd. can help businesses achieve their goals and succeed in their respective markets.