The TPU Tube, or Thermoplastic Polyurethane Tube, is a versatile and durable conduit widely used for fluid transportation in various industries, including medical, laboratory, and industrial sectors. Composed of thermoplastic polyurethane, these tubes offer exceptional flexibility, and resistance to abrasion, chemicals, and environmental factors, ensuring longevity and reliable performance in demanding conditions.

Demax, a leading manufacturer in the industry, is renowned for producing high-quality TPU tubes that meet stringent industry standards. Their meticulous manufacturing process, from selecting premium materials to implementing advanced production techniques, guarantees tubes that deliver unmatched performance and durability. With a commitment to innovation and customization, Demax continuously enhances its product offerings to meet specific customer needs, making it a trusted choice for professionals seeking dependable TPU tubing solutions.

What is a TPU Tube?

A Thermoplastic Polyurethane (TPU) Tube is a flexible conduit utilized primarily for fluid transportation across various industries, including medical, laboratory, and industrial sectors. The tube’s composition of thermoplastic polyurethane provides it with remarkable flexibility, durability, and resistance to a broad range of environmental factors, ensuring its suitability for diverse applications.

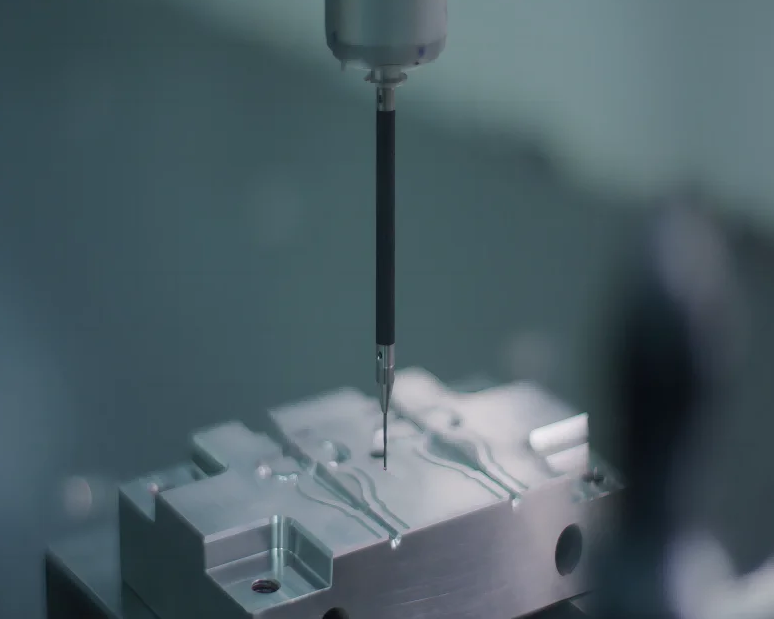

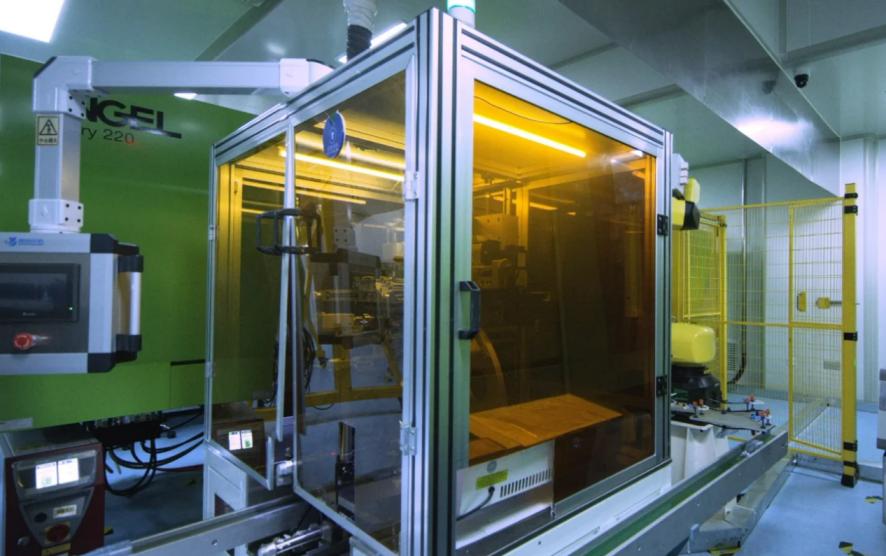

Demax TPU tubes are meticulously crafted from Thermoplastic Polyurethane, a premium synthetic polymer known for its exceptional elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This material composition guarantees the longevity and reliability of the tubes, even in the most demanding conditions. Demax’s commitment to quality extends through every phase of their manufacturing process, from sourcing the finest materials to employing advanced production techniques.

The Benefits of TPU Tubes

Exceptional Durability

One of the primary benefits of TPU tubes is their exceptional durability. The synthetic polymer composition endows the tubes with high resistance to wear and tear, making them suitable for long-term use in challenging environments. This durability translates to reduced maintenance and replacement costs, providing significant economic benefits to industries relying on these tubes.

High Flexibility

TPU tubes possess high flexibility, allowing them to bend and conform to various shapes and configurations without sacrificing structural integrity. This flexibility simplifies installation and enhances maneuverability in complex systems, reducing installation time and labor costs. Whether used in intricate medical procedures or extensive industrial processes, the flexibility of TPU tubes ensures ease of use and operational efficiency.

Chemical and Environmental Resistance

Another notable advantage of TPU tubes is their resistance to a wide array of chemicals and environmental factors. This resistance ensures that the tubes maintain their integrity and performance when exposed to harsh substances and conditions, making them ideal for applications involving corrosive fluids or extreme environments. The ability to withstand such challenging conditions without degradation is a testament to the robustness of TPU tubes.

Applications of TPU Tubes

Medical Industry

Medical Procedures

In the medical industry, TPU tubes are commonly used in various procedures due to their biocompatibility and flexibility. Their ability to maintain unobstructed fluid flow is critical in applications where precise fluid control and consistency are essential. The single lumen design with a seamless interior pathway prevents blockages, ensuring optimal performance during medical procedures.

Laboratory Experiments

TPU tubes are also extensively used in laboratory settings. Their transparency allows for real-time observation of fluid flow, enabling researchers and technicians to monitor experiments closely and detect abnormalities promptly. This feature is particularly valuable in applications requiring precise fluid management and consistency.

Customization for Specialized Applications

Demax’s commitment to research and development has led to the creation of TPU tubes with innovative features tailored to specific customer needs. Customization options allow for precise adjustments in tube size and configuration, catering to specialized medical and laboratory applications. This level of customization ensures that the tubes meet stringent industry standards and perform reliably in critical situations.

Industrial Applications

Fluid Handling

In industrial settings, TPU tubes are used for fluid handling due to their ability to accommodate different fluid volumes and flow rates. Available in a broad range of sizes, TPU tubes cater to diverse application requirements, from small diameters suited for intricate systems to larger diameters for high-volume fluid transportation. Their durability and resistance to chemicals make them ideal for handling various industrial fluids.

Environmental Applications

TPU tubes are also employed in environmental applications, such as waste management and pollution control. Their chemical resistance ensures that they can transport hazardous fluids without degradation, maintaining safety and efficiency in these critical operations. The reliability of TPU tubes in harsh environmental conditions underscores their importance in sustainable industrial practices.

Automation and Robotics

The flexibility and durability of TPU tubes make them suitable for use in automation and robotics. Their ability to withstand repetitive movements and mechanical stress without compromising performance is crucial in automated systems. TPU tubes facilitate the smooth operation of robotic equipment, enhancing productivity and efficiency in industrial processes.

How to Use TPU Tube

Installation Process

Preparation

Before installation, it is essential to prepare the TPU tubes by ensuring they are clean and free of any obstructions. Inspect the tubes for any visible defects or damage that could affect performance. Proper preparation ensures the longevity and reliability of the tubes in their intended application.

Bending and Shaping

Due to their high flexibility, TPU tubes can be easily bent and shaped to fit various configurations. Care should be taken to avoid sharp bends that could compromise the structural integrity of the tubes. Using appropriate tools and techniques for bending ensures that the tubes maintain their performance and durability.

Securing and Connecting

Securing and connecting TPU tubes requires the use of suitable fittings and clamps. Ensure that all connections are tight and secure to prevent leaks and ensure smooth fluid flow. Regular inspection of connections and fittings is recommended to maintain optimal performance and prevent any issues during operation.

Maintenance and Care

Regular Inspection

Regular inspection of TPU tubes is crucial to identify any signs of wear or damage. Check for any cracks, leaks, or abrasions that could affect the tubes’ performance. Promptly addressing any issues ensures that the tubes continue to function reliably and prevents potential failures.

Cleaning and Sterilization

In medical and laboratory applications, cleaning and sterilizing TPU tubes are essential to maintain hygiene and prevent contamination. Use appropriate cleaning agents and sterilization methods compatible with TPU material to ensure thorough cleaning without damaging the tubes. Regular cleaning and sterilization prolong the lifespan of the tubes and ensure their safe use.

Replacement and Disposal

Despite their durability, TPU tubes may eventually need replacement due to wear and tear. Ensure that replacement tubes meet the same quality standards as the original ones to maintain performance consistency. Proper disposal of used TPU tubes is essential to adhere to environmental regulations and promote sustainability.

Why Choose Demax TPU Tubes

Superior Quality and Reliability

Demax TPU tubes stand out for their superior quality and reliability. Renowned for meeting stringent industry standards, Demax ensures consistent performance crucial for critical applications like medical procedures and industrial processes. The meticulous crafting process, from sourcing the finest materials to employing advanced production techniques, guarantees the highest level of quality in every tube.

Innovation and Customization

With a commitment to research and development, Demax continually enhances its TPU tube designs, offering innovative features tailored to customer needs. Customization options allow for precise adjustments, ensuring that the tubes meet specific application requirements. This focus on innovation and customization sets Demax apart as a leader in the TPU tube industry.

Excellent Customer Support

Demax provides excellent customer support, ensuring prompt assistance and delivery reliability. Their dedication to customer satisfaction is evident in their responsive service and commitment to addressing customer needs effectively. For those seeking dependable TPU tubes with a proven track record, Demax emerges as a top choice, balancing quality and affordability to provide cost-effective solutions without compromising performance.

Conclusion

TPU tubes, particularly those from Demax, offer exceptional durability, flexibility, and resistance to environmental factors, making them suitable for a wide range of applications in the medical, laboratory, and industrial sectors. Their superior quality, innovative features, and customization options make them the preferred choice for professionals seeking reliable and high-performing tubes. With a commitment to excellence and customer satisfaction, Demax TPU tube stands out as a top solution for critical fluid transportation needs.