Imagine being in the midst of a life-saving procedure where the instruments must match the precision of a surgeon’s hand, yet remain flexible enough to move through the intricate maze of veins and arteries. These tiny, sophisticated tools are engineering wonders, with a critical component at their core: the coil shaft. What makes this component so crucial, and how does it shape the future of healthcare? To understand this, we need to explore the detailed engineering behind coil shafts and the pivotal role they play in modern medical devices.

Coil Shaft Engineering: Reliability in Critical Medical Devices

The design and creation of coil shafts for medical applications center on one crucial aim: ensuring their reliability. These shafts must perform flawlessly, especially in high-pressure environments such as surgeries or minimally invasive procedures. Precision, strength, and safety all need to be carefully balanced, with each element influenced by the structure and materials chosen for the shaft.

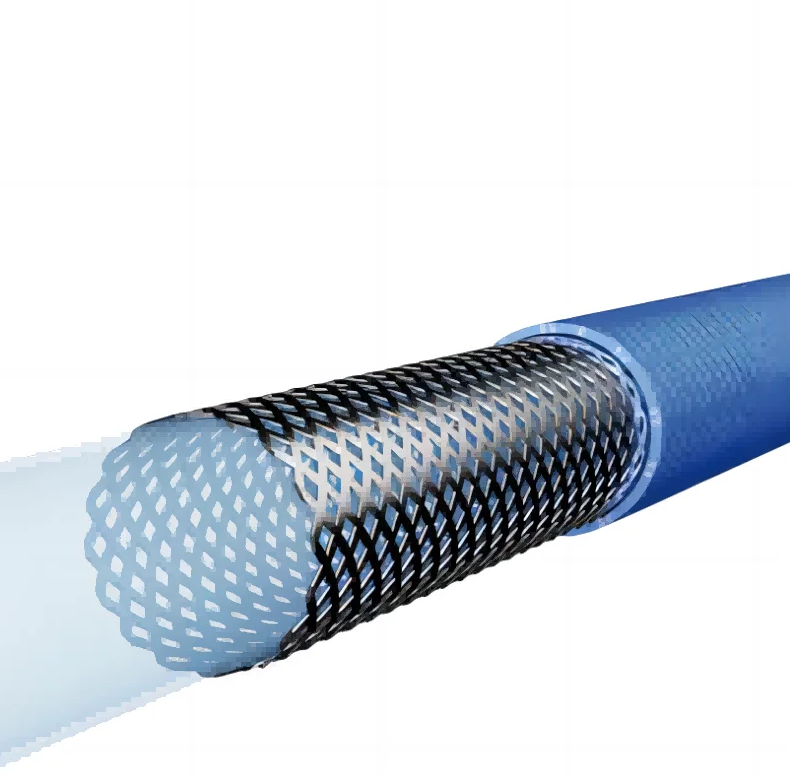

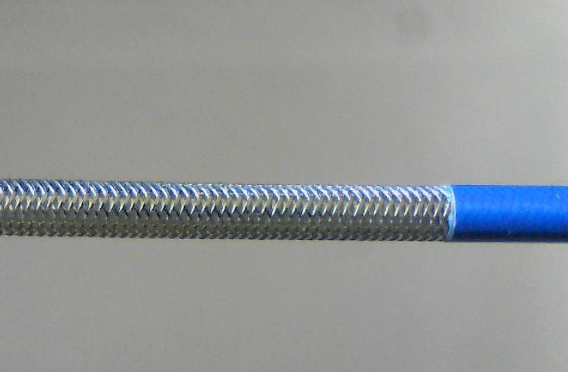

Outer Layer Durability:

Typically made from TPU (thermoplastic polyurethane), Pebax, or PA (polyamide), the outer layer provides the necessary flexibility and resilience. These materials, beyond their durability, ensure a smooth surface, which is essential for minimizing friction as the shaft navigates through the body. This allows for seamless movement during complex medical procedures.

Middle Layer Strength:

Beneath the outer layer, the middle section—composed of materials like SUS304 stainless steel, nickel-titanium, or braided wire—provides the rigidity and torque essential for maintaining the shaft’s form during use. This layer is critical when precise control is required. Depending on the specific application, the wire may be round or flat, with different braid patterns or spring configurations tailored for optimized performance.

Inner Layer Precision:

Just as vital is the inner layer, often constructed from PTFE (polytetrafluoroethylene), TPU, or Pebax. Its role is to reduce friction, ensuring that fluids or surgical tools pass through smoothly. With each material in this multi-layer structure carefully selected, the result is a shaft that’s both strong and delicate enough to handle sensitive tasks in demanding medical environments.

Technical specifications like inner diameter, wall thickness, and outer diameter tolerance are precisely controlled, ensuring these shafts meet the stringent requirements of various medical procedures. Additionally, factors like coil spacing and weaving density are customized, enabling optimal performance for specific medical applications.

Coil Shafts in Cardiology: Precision in Catheter-Based Treatments

Cardiology, one of the most significant fields relying on coil shafts, sees their use in catheter-based treatments. A millimeter’s difference in precision can impact outcomes, making these shafts essential for guiding catheters through the body’s intricate vascular systems.

Guiding Angiography Catheters with Precision:

In angiography, where physicians need to visualize blood vessels, the coil shaft’s ability to enable precise catheter movement is critical. Allowing accurate navigation through the vascular system ensures that doctors obtain clear images, guiding their next steps in treatment.

Microcatheters for Delicate Work:

For even more sensitive procedures, like those involving brain vessels, microcatheters equipped with coil shafts become indispensable. They allow doctors to navigate the smallest and most complex vascular pathways, ensuring that conditions like aneurysms are treated without damaging surrounding tissues.

Safety and Improved Outcomes:

The incidence of complications such as vascular damage or rupture is significantly reduced. Due to the use of biocompatible materials, the risk of infection or other adverse reactions is also minimized. This brings safer results to patients.

Coil Shafts for Laparoscopic Surgery: Enabling Less Invasive Procedures

Laparoscopic surgery, favored for its minimal invasiveness, heavily relies on instruments equipped with coil shafts to carry out intricate operations through small incisions. These shafts must offer both flexibility and durability, ensuring precision even in tight spaces.

Operability in Confined Spaces:

Instruments used in laparoscopic surgery must bend and maneuver without losing their structural integrity. The coil shaft enables this flexibility, allowing surgeons to operate efficiently within the limited space in the body. Reducing patient recovery time and postoperative complications.

Delivering High Torque and Pushing Force:

Another essential function of these shafts is their ability to provide high torque and pushing force. This ensures that surgeons can apply the necessary pressure to the instruments while maintaining control, even in complex operations, all without causing excessive trauma to the patient.

Anti-Explosion and Anti-Bending Properties:

Coil shafts are also designed to endure high stress and pressure during surgeries. Its explosion-proof and anti-bending properties ensure that the shaft remains intact. It eliminates the risk of sudden breakage or deformation that could endanger patient safety.

Coil Shafts in Endovascular Surgery: Enhancing Precision and Safety

Endovascular surgery, which treats vascular diseases from within the vessels themselves, is another field heavily reliant on the flexibility and precision of coil shafts. Their use reduces the need for open surgery by allowing for safe and accurate navigation of the body’s vascular system.

Safe Navigation through Blood Vessels:

In endovascular procedures, the coil shaft must be both flexible and strong. To enable the catheter to move through the body’s complex network of blood vessels. Whether treating aneurysms, embolisms, or stenosis, these shafts ensure that catheters reach the target site without damaging fragile vessel walls.

Minimizing the Risk of Complications:

The smooth surface of these shafts reduces friction during insertion, minimizing the risk of vessel damage. Furthermore, their biocompatibility ensures that they do not trigger immune responses or infections, thus enhancing the safety and success rate of the procedure.

Customization for Precision:

Many endovascular procedures require a highly specialized approach. Adjustments in coil spacing, weaving density, and spindle numbers allow coil shafts to be customized to meet the precise demands of each surgery, ensuring optimal performance.

Medical-Grade Materials: Ensuring Biocompatibility and Safety

One of the most important aspects of coil shaft design is the use of medical grade materials to ensure performance and safety. These materials must adhere to strict biocompatibility standards. To reduce the risk of adverse reactions while providing the durability required for long-term use.

Reducing the Risk of Adverse Reactions:

Materials like TPU, Pebax, and stainless steel are chosen for their ability to interact safely with human tissues. This selection lowers the risk of complications, such as infections or allergic reactions, ensuring that the shaft can be safely used in medical procedures.

Long-Term Durability:

Coil shafts, particularly those used in long-term procedures such as guide sheaths or distal access catheters, must be exceptionally durable. Their construction ensures they maintain integrity throughout prolonged use without compromising performance.

Patient Safety as the Focus:

At the heart of coil shaft engineering is patient safety. By utilizing biocompatible materials and optimizing the shaft design for specific medical needs, manufacturers like Tianjin Demax Medical Technology Co., Ltd. produce reliable and safe devices that support successful outcomes in critical medical procedures.

Conclusion

Coil shafts are indispensable in the medical world, providing the precision, flexibility, and durability required in various medical procedures, from cardiology to laparoscopic surgery. As medical technology continues to advance, innovations in coil shaft design will lead to more effective and sophisticated tools. Enhance the overall impact of modern healthcare and improve patient outcomes.