Imagine being in the midst of a complex medical procedure where every precise move counts. The surgeon’s tools play a vital role, and among them is one indispensable device—the guidewire. Small but essential, it navigates the body’s intricate vascular system, helping to achieve success while minimizing risks. But what guarantees that this tool is both safe and reliable? The answer lies in uncoated stainless steel guidewire, crafted with durability and precision in mind. This article explores how these guidewires ensure safety in medical procedures and why they continue to be regarded as a gold standard in the field.

How Uncoated Stainless Steel Guidewires Support Medical Innovation

Uncoated stainless steel guidewires have become key drivers of innovation in modern medical procedures, thanks to their unique properties. These tools have fundamentally changed the way surgeons approach complex anatomical structures.

Precision and Flexibility

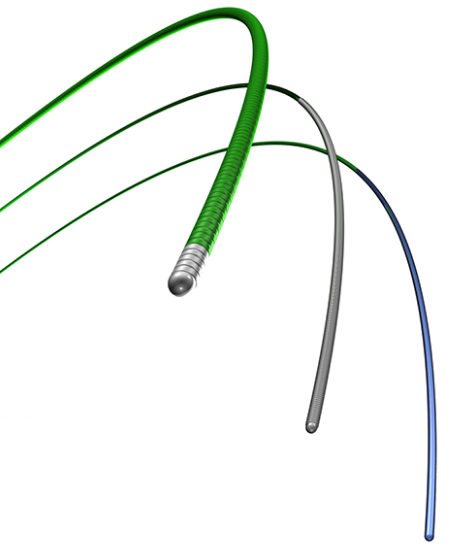

One of the most significant advantages of these guidewires is their exceptional flexibility and torque response. Made from stainless steel, they provide precise navigation through the most challenging vessels and anatomical pathways, which is essential for procedures like angioplasty or catheterization. Their smooth, controlled movement reduces the risk of trauma to vessels, ensuring that the procedure goes smoothly while minimizing complications. This precision is critical for better outcomes, safeguarding both the patient and the success of the intervention.

Durability for Challenging Procedures

Many medical procedures, particularly those that involve diagnostic or interventional techniques, demand tools that can endure substantial stress. The uncoated stainless steel guidewires produced by Tianjin Demax Medical Technology Co., Ltd., are engineered to withstand such conditions. The high-strength stainless-steel core provides superior pushability and support, which enables physicians to guide them through difficult-to-reach areas without worrying about their structural integrity. This durability is a major factor in ensuring that these wires perform optimally throughout procedures, enhancing safety and reliability.

Smooth Surface to Minimize Trauma

Another critical feature that ensures patient safety is the smooth surface finish of these guidewires. Reducing friction as they move through the body’s vascular system is essential to lower the risk of vessel trauma. The smooth passage of these wires helps prevent injuries like perforations or vessel dissections, making them a vital component in both routine and complex medical procedures. This combination of precision and safety places uncoated stainless steel guidewires among the top choices for medical professionals.

The Evolution of Uncoated Stainless Steel Guidewires in Surgical Technology

The development of uncoated stainless steel guidewires marks a milestone in surgical technology. Over time, these guidewires have evolved to meet the growing demands of modern medicine, combining advanced material science with enhanced performance features.

Historical Advancements in Material Science

The history of stainless steel in medical guidewires goes back decades. As material science advanced, the stainless steel alloys used in these wires became increasingly refined. This progression enhanced their flexibility, strength, and biocompatibility, leading to the superior guidewires available today. These wires are now commonly used in everything from cardiovascular interventions to endoscopic procedures, proving their versatility and effectiveness in clinical settings.

Radiopaque Markers for Improved Visibility

Today’s uncoated stainless steel guidewires, including those from Tianjin Demax Medical Technology Co., Ltd., are equipped with radiopaque markers. These markers greatly improve visibility under fluoroscopy, allowing physicians to track and position the guidewire with pinpoint accuracy. Enhanced visibility leads to safer navigation through complex anatomy, ensuring that medical teams can continuously monitor the guidewire’s progress and make real-time adjustments, ultimately improving the procedure’s overall safety.

Custom Configurations for Varied Procedures

With advancements in surgical technology, the versatility of uncoated stainless steel guidewires has expanded. These wires are available in different configurations, such as straight and J-tip designs, catering to a variety of procedural needs and anatomical challenges. This adaptability makes them an indispensable tool across a wide range of diagnostic and interventional procedures, ensuring that healthcare providers can tailor their approach based on patient-specific factors.

Why Uncoated Stainless Steel Guidewires Remain a Gold Standard in Medicine

In medicine, safety and dependability are non-negotiable. Uncoated stainless steel guidewires have maintained their status as a gold standard in the field due to their consistent performance and reliability. But what keeps them ahead of other options?

Superior Puncture Performance

The ability of uncoated stainless steel guidewires to deliver outstanding puncture performance makes them ideal for procedures requiring precise navigation. Constructed from high-quality stainless steel, as exemplified by Tianjin Demax Medical Technology Co., Ltd., these guidewires offer a perfect balance of flexibility and strength. This allows them to puncture through difficult anatomical structures without causing excessive trauma, ensuring safer, more efficient procedures.

Cost-Effectiveness and High Efficiency

Another reason these guidewires are highly regarded is their cost-effectiveness. Despite their top-tier performance and durability, they remain relatively affordable when compared to other coated alternatives. For healthcare facilities looking to balance cost with quality, uncoated stainless steel guidewires provide an attractive solution without compromising on safety. Their reliability and efficiency make them an enduring choice across various medical specialties.

Proven Reliability in Clinical Use

These guidewires have a long-standing track record of success in both diagnostic and interventional procedures. Their ability to offer precise navigation, durability, and safety has earned them the trust of healthcare professionals worldwide. Whether used in cardiovascular, gastrointestinal, or urological applications, uncoated stainless steel guidewires have consistently delivered superior results. This sustained reliability solidifies their role as a critical tool in modern medical practice.

Uncoated Stainless Steel Guidewires: A Critical Component for Safe and Effective Surgeries

When the success of a medical procedure hinges on the tools used, uncoated stainless steel guidewires emerge as critical players. Designed to prioritize safety, flexibility, and precision, these guidewires, such as those from Tianjin Demax Medical Technology Co., Ltd., are indispensable in the operating room.

High Flexibility for Navigating Complex Anatomies

Flexibility is crucial when navigating through complex or delicate anatomical structures. The high flexibility of uncoated stainless steel guidewires allows surgeons to maneuver through even the most tortuous vessels with minimal difficulty. This reduces stress on surrounding tissues, lowering the risk of complications during surgery and improving patient outcomes.

Smooth Surface Reduces Risk of Vessel Trauma

Another essential feature that enhances the safety of these guidewires is their smooth surface finish. By minimizing friction as they move through the vascular system, the risk of vessel trauma or injury is drastically reduced. A smoother journey through blood vessels translates to fewer postoperative complications, contributing to quicker recovery times and better overall patient experiences.

Radiopaque Markers Ensure Precise Navigation

The inclusion of radiopaque markers enhances the precision of surgical procedures by improving visibility under imaging techniques like fluoroscopy. These markers allow surgeons to position the guidewire and other devices with accuracy, contributing to better procedural outcomes and enhanced safety. This precision is invaluable in ensuring that surgeries are conducted efficiently and without unnecessary risk.

Conclusion

Uncoated stainless steel guidewires have become indispensable tools in modern medical procedures, delivering unmatched safety, flexibility, and durability. Their smooth surface, various configurations, and radiopaque markers make them essential for diagnostic and interventional surgeries. As technology continues to advance, these guidewires will remain a gold standard in the medical field, supporting safer, more effective surgeries that benefit both patients and healthcare professionals alike.