What is a Hydrophylic Coated Guidewire?

A Hydrophylic Coated Guidewire, considered a fundamental tool in modern medical practice, plays a crucial role in various procedures, including angioplasty, stenting, and urological surgeries. But what gives these wires such irreplaceable value in the field? Their effectiveness can be traced back to a combination of cutting-edge design and the use of specialized materials. At its core, this guidewire consists of a thin, flexible structure, treated with a hydrophilic coating that absorbs and retains water. This coating’s unique properties cause the wire to become highly slippery when exposed to bodily fluids, enabling it to maneuver effortlessly through tight, winding blood vessels while greatly minimizing friction. As a result, the risk of damage to vessel walls, even during complex procedures, is significantly reduced.

In fields where precision distinguishes success from complications, the Hydrophylic Coated Guidewire excels by improving both safety and procedural efficiency. By combining structural strength with a water-attracting surface, it achieves an optimal balance of flexibility and support, granting healthcare professionals greater control when performing delicate interventions with enhanced confidence.

The Composition of Hydrophylic Coated Guidewires

Core Materials: Stainless Steel and Nitinol

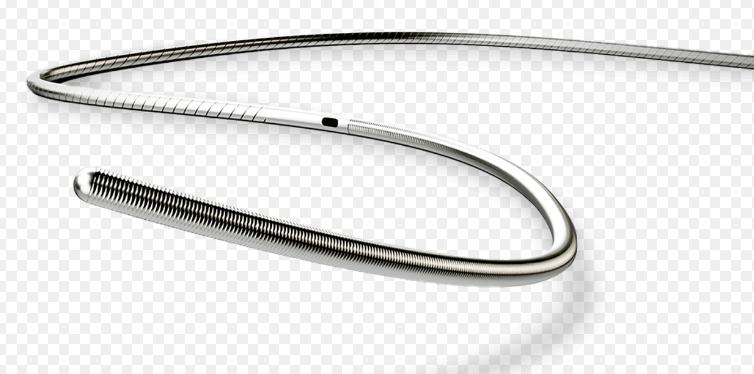

The internal structure of a Hydrophylic Coated Guidewire typically revolves around either stainless steel or nitinol as the core material. Stainless steel, renowned for its rigidity and structural durability, offers the necessary stability in situations where strength is critical. This material ensures that the guidewire can endure the physical stresses it encounters while threading through the body’s complex and intricate pathways.

Nitinol, however, takes the sophistication of guidewires to another level. Nitinol is known for its exceptional flexibility and ability to return to its original shape (shape memory). It allows the guidewire to bend and conform to the natural curves of the body without losing its structural integrity. This ability is critical in procedures that require the guidewire to twist through blood vessels. It conforms to the contours of the vessel while ensuring durability and reducing the potential for injury to nearby tissues. By combining the stability of stainless steel with the adaptability of Nitinol. The guidewire achieves an ideal synergy of flexibility and strength, resulting in a tool with excellent maneuverability and long life.

Hydrophilic Coating: Minimizing Friction, Improving Navigation

The hydrophilic coating applied to these guidewires, typically made from polytetrafluoroethylene (PTFE) or other similar materials, serves as a slick layer of lubrication on the wire’s surface. Through a highly specialized manufacturing process, this coating is applied with meticulous precision to ensure even distribution and longevity. Once the guidewire comes into contact with bodily fluids, the hydrophilic coating activates, drastically lowering friction and allowing the wire to glide effortlessly through the body’s vessels and passages.

This seamless movement along the vessel wall helps speed up the procedure. By reducing the risk of accidentally damaging sensitive tissue, it not only makes the procedure faster, but also safer. The uniformity and durability of the coating ensures that the guidewire maintains its smooth properties throughout the procedure. Providing consistent, reliable control to medical professionals.

Key Features of Hydrophylic Coated Guidewires

Superior Flexibility for Complex Procedures

One of the key characteristics that set Hydrophylic Coated Guidewires apart from others is their exceptional flexibility. This trait, thanks to the use of nitinol, allows the wire to twist and bend without compromising its integrity. This flexibility is especially important during highly complex surgeries. Because it is difficult for a harder guidewire to pass through the narrow and tortuous vascular pathways of the human body. The perfect combination of flexibility and support allows medical professionals to precisely manipulate the guidewire, making it easier to reach hard-to-reach areas. All while minimizing the risk of damage to surrounding tissue.

The ability to guide a guidewire through narrowed or blocked vessels becomes a key advantage. The reduced resistance combined with the increased control greatly increases the success rate of the procedure. This helps improve patient outcomes.

Radiopaque Markers for Enhanced Visualization

In any invasive procedure, accurate visualization of the guidewire’s position is essential, particularly when navigating through complex internal structures. Hydrophylic Coated Guidewires often come equipped with a radiopaque marker at their distal end. This marker becomes visible under fluoroscopy, a real-time X-ray imaging technique used during medical procedures to help clinicians monitor the guidewire’s movement within the body.

This feature allows healthcare professionals to track the wire’s precise location, thus preventing potential misplacement and enhancing overall safety. Whether positioning a stent in a coronary artery or navigating the renal system during urological surgery, the enhanced visibility provided by the radiopaque marker ensures that the procedure is performed with heightened precision, minimizing the risk of errors and complications.

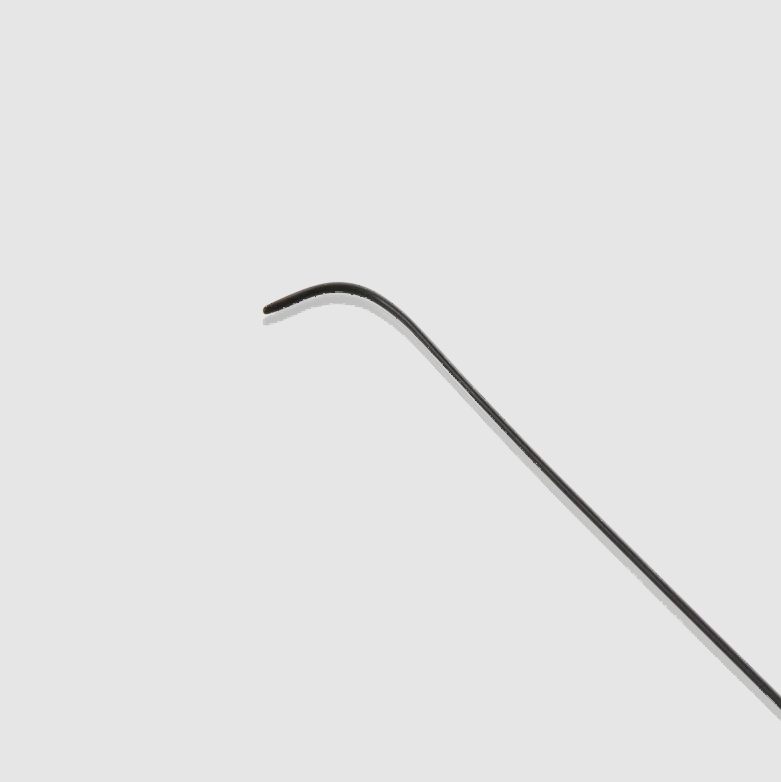

Smooth Tapered Tips for Seamless Transitions

A Hydrophylic Coated Guidewire also boasts a tapered tip, a design element that facilitates smoother transitions when inserting the wire into vessels. This tapered design minimizes trauma to tissues, ensuring that the wire can enter even delicate structures with minimal resistance. It becomes particularly important when working in sensitive areas, such as coronary arteries or the urinary system, where avoiding tissue damage is critical to patient safety.

By reducing the likelihood of blood vessel injury during insertion. The tapered tip not only protects the patient but also improves the overall success rate of the procedure. This feature enhances the guidewire’s versatility. Allowing it to be used in a wide range of medical applications without causing unnecessary harm.

Hydrophylic Coated Guidewires in Clinical Practice

Cardiovascular Procedures

In cardiovascular medicine, Hydrophylic Coated Guidewires have become a staple, particularly in interventions like angioplasty and stenting. These wires enable physicians to navigate through the coronary arteries, which are often narrowed due to plaque buildup, and deploy stents or balloons. The hydrophilic coating significantly reduces friction, making it easier for the wire to pass through tight or occluded arteries without damaging the delicate vessel walls. Moreover, the guidewire’s flexibility and visibility under fluoroscopy help ensure precise placement of devices, ultimately improving patient outcomes.

Urological Applications

In the field of urology, Hydrophylic Coated Guidewires are frequently utilized to navigate through the urinary tract. Procedures like ureteroscopy, where the urinary system is accessed to remove kidney stones, greatly benefit from these wires. The slippery hydrophilic coating reduces friction, allowing the wire to pass through the urinary system smoothly and with less risk of injuring fragile tissues. This not only makes the procedure more efficient but also enhances patient safety.

Other Interventional Uses

Beyond cardiovascular and urological applications, Hydrophylic Coated Guidewires are used in various interventional procedures. These include endovascular surgeries where precise delivery of catheters or embolization materials is necessary. Due to its excellent flexibility, reduced friction and enhanced visibility. These guidewires are valuable tools in a variety of minimally invasive procedures and help improve navigation through challenging anatomical pathways.

Why Choose Tianjin Demax Medical Technology Co., Ltd.?

When selecting a supplier for Hydrophylic Coated Guidewires, Tianjin Demax Medical Technology Co., Ltd. offers an unparalleled advantage. With over a decade of experience in OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, Demax has cultivated strategic partnerships with leading European and American companies. Their dedication to innovation, quality assurance, and customer satisfaction has cemented their reputation in the medical industry.

Demax’s multidisciplinary research and development team, which makes up 40% of the company, is committed to pushing the boundaries of medical technology. Supported by state-of-the-art production equipment, proprietary patented technologies, and fully automated production lines, Demax delivers high-quality products with consistency. They offer rapid mass production capabilities, coupled with professional after-sales support. making them a trusted partner to healthcare providers around the world.

Conclusion

Hydrophilic coated guidewires represent a revolutionary advancement in medical technology. Providing increased dexterity, reduced friction, and improved visibility in a variety of clinical procedures. Whether used for cardiovascular surgery, urology, or other minimally invasive procedures. These guidewires allow medical professionals to navigate complex anatomical pathways more easily and accurately.

Choosing a reliable supplier like Tianjin Demax Medical Technology Co., Ltd. ensures that healthcare providers have access to high-quality, innovative guidewires that meet the demands of modern medicine. As technology and techniques continue to evolve, Hydrophylic Coated Guidewires will remain at the forefront of medical innovation, enhancing both procedural success and patient outcomes.