The rapid transformation within the medical device industry, fueled by technological breakthroughs and an ever-increasing demand for superior, precise medical instruments, presents a compelling question: who holds the expertise to convert these cutting-edge concepts into physical, life-saving devices? Among the pivotal entities in this complex process is the Original Design Manufacturer (ODM). But what role does a Medical Product ODM play in turning innovative ideas into reality?

Defining Medical Product ODM: A Comprehensive Service

An Original Design Manufacturer (ODM) of medical products is a company responsible for both the design and production of medical devices according to a client’s specific requirements. However, this service is far more expansive than merely producing equipment. It involves managing the entire product development cycle, from conceptual design to the final realization of the product, ensuring that the device complies with rigorous regulatory frameworks. For companies that lack internal resources for designing and manufacturing medical tools, ODM services offer a highly valuable, all-encompassing solution.

Demax: A Leading Supplier in the Medical ODM Sector

One prominent figure in the Medical Product ODM landscape is Demax. With close to a decade of experience and a portfolio spanning a variety of medical devices and solutions, Demax has distinguished itself by delivering exceptional-quality medical products, such as medical catheters, guide wires, and precision tubing, among others. Nearly 40% of Demax’s workforce is dedicated to research and development (R&D), enabling the company to build strategic partnerships with international clients in need of bespoke solutions for medical product manufacturing.

Precision Medical Tubing: A Crucial Element in Healthcare

In many medical devices, particularly those involved in procedures like catheterization or fluid infusion, precision medical tubing plays a vital role. These tubes must adhere to stringent quality and safety standards due to their use in life-saving operations. Demax excels in providing world-class precision medical tubing, meeting the high demands of medical procedures.

The Importance of Precision

In the realm of medical tubing, the margin for error is extraordinarily narrow. Even the slightest flaw could lead to device malfunction, potentially jeopardizing a patient’s safety. Therefore, precision in manufacturing is critical to guarantee smooth and uninterrupted fluid delivery while reducing the risk of complications during medical procedures. Demax employs cutting-edge manufacturing technologies and utilizes high-grade materials to produce tubing that is not only durable but also flexible and safe for use in medical environments.

Customization to Fulfill Specific Requirements

Each medical procedure often requires tubing with unique characteristics. For instance, cardiovascular catheters necessitate extremely flexible, small-diameter tubing, while dialysis machines rely on larger, more rigid tubes. Demax offers an array of customization options to ensure that every client’s unique specifications are fulfilled with the utmost precision.

Regulatory Compliance as a Safety Measure

Medical catheters are governed by strict international regulations. Such as ISO 13485, a regulation that certifies that a product meets necessary safety and quality benchmarks. Demax ensures that its precision medical tubing meets these regulations through a comprehensive quality assurance system. This provides healthcare providers and patients with the highest confidence in product safety and performance.

Medical Guide Wires: Precision Crafting for Critical Procedures

Another key area of expertise for Demax is the production of medical guide wires, which are crucial in various minimally invasive medical procedures. Guide wires are thin, flexible instruments that assist in navigating catheters or other devices through the intricate pathways of the body, such as blood vessels or the gastrointestinal tract.

Precision Engineering and High-Quality Materials

The manufacturing of medical guide wires demands an intricate balance of flexibility and strength. The wires must maintain their flexibility for ease of navigation while being robust enough to endure the complexities of invasive procedures. Demax employs high-grade materials such as stainless steel and nitinol, which offer the ideal combination of strength, flexibility, and biocompatibility. These features ensure the safety and effectiveness of guide wires in delicate procedures like angioplasties, where precision is critical to patient outcomes.

Tailored Solutions for Specific Medical Procedures

As with tubing, the demands on guide wires vary depending on the procedure they are used in. Demax offers a range of customized guidewire solutions designed to meet the exact needs of various medical interventions. Whether used in cardiology or gastroenterology, Demax’s guidewires are tailored to help healthcare professionals perform their jobs with optimal efficiency and safety.

Adhering to Global Standards for Safety and Quality

To ensure that its guide wires are not only safe but also effective, Demax adheres to global regulatory standards. This commitment to meeting international guidelines has earned the company a reputation for delivering reliable and trusted products across healthcare sectors worldwide.

Injection Molding: A Critical Process in Medical Manufacturing

Injection molding forms the backbone of many medical devices, particularly for creating components with complex shapes and fine details. This process is vital for producing a wide variety of medical products, ranging from surgical instruments to single-use components used in diagnostic and therapeutic devices.

Precision Molding for Complex Medical Parts

The injection molding process allows for the high-volume production of medical parts with intricate geometries and exact tolerances. Demax’s expertise in this field enables the company to manufacture complex components requiring the highest precision. Ensuring each product meets the stringent standards required for medical applications.

Economic Benefits of Injection Molding

Injection molding not only delivers high-quality results but also offers significant cost advantages for large-scale production. Demax’s capabilities in the design and manufacture of injection molds enable clients to reduce their costs while maintaining high-quality standards. In a field where affordability can significantly affect access to life-saving devices, this cost efficiency is a crucial factor.

Ensuring Safety Through Compliance

Similar to other areas of medical manufacturing, injection molding requires strict adherence to international regulations to guarantee patient safety. Demax implements a robust quality control system to ensure that every molded part meets regulatory standards. Providing peace of mind for both medical device manufacturers and healthcare providers.

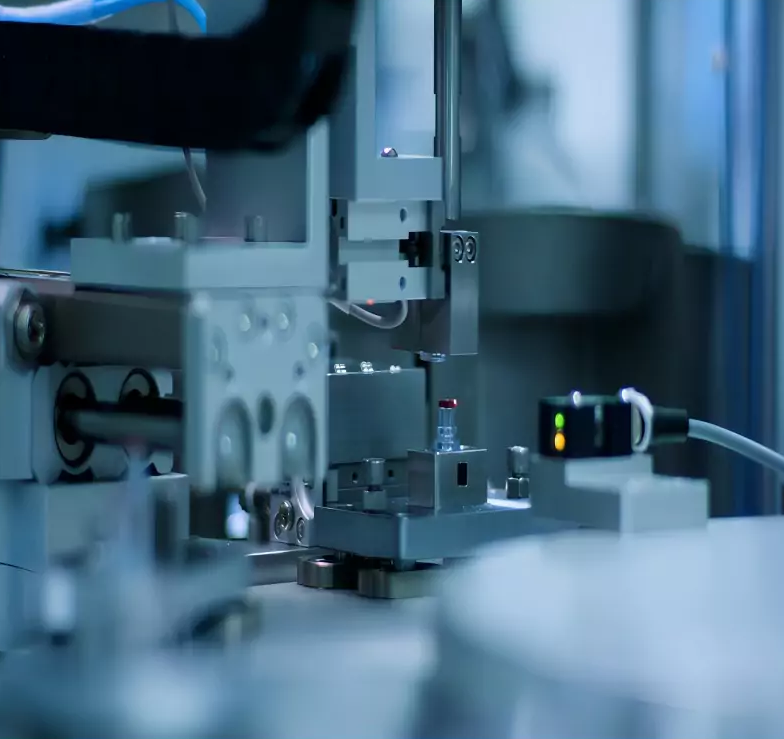

Intelligent Manufacturing: The Future of Medical Device Production

As industries across the globe embrace cutting-edge technologies, the medical device sector is no exception. Intelligent manufacturing—which integrates automation, data analytics, and artificial intelligence (AI)—is rapidly transforming production processes. Demax is at the forefront of this movement, leveraging intelligent manufacturing to improve efficiency, enhance product quality, and minimize production costs.

Automation for Greater Consistency

At the heart of Demax’s intelligent manufacturing approach lies automation. Automated production lines ensure uniformity and reduce the likelihood of human error, which is essential in industries where even minor inconsistencies can have significant consequences. Demax’s investment in automation has positioned it as a leader in producing reliable, high-quality medical devices.

Data Analytics for Continuous Improvement

By incorporating real-time data analytics into the production process, Demax is able to monitor operations continuously and make immediate adjustments. This data-driven approach enhances efficiency, reduces material waste, and ensures that the end product consistently meets exact client specifications.

A Forward-Thinking, Future-Ready Approach

With the increasing adoption of smart technologies across healthcare industries, Demax’s intelligent manufacturing capabilities offer clients a forward-looking solution for their production needs. From AI-driven process optimization to robotic automation, Demax is committed to advancing the possibilities of medical product manufacturing.

Comprehensive ODM Services: Custom Solutions from Start to Finish

Demax’s ability to provide Medical Product ODM services for medical devices is its core strength. This service offering provides a complete solution for companies seeking to design, develop, and produce high-quality medical products.

Full Product Lifecycle Support

Demax’s Medical Product ODM services encompass the entire product lifecycle—from the initial design concept through to production and delivery. This end-to-end support simplifies the development process for medical companies, particularly those lacking the in-house resources for product development. Demax’s experienced R&D team works closely with each client to understand their needs and deliver bespoke solutions.

Long-Standing Partnerships for Mutual Success

With nearly a decade of experience, Demax has established strategic partnerships with international medical device manufacturers. These partnerships reflect Demax’s commitment to innovation, reliability, and quality, allowing medical companies to focus on their core competencies while trusting Demax to handle the intricacies of product development.

Accelerating Time to Market

One of the biggest challenges facing the medical device industry is getting products to market quickly. Without compromising regulatory compliance. Demax’s expertise in product development and regulatory compliance enables clients to accelerate time to market. While maintaining the highest safety standards, giving them a competitive advantage in this rapidly evolving industry.

Conclusion: Why Demax is the ODM Partner You Need

In a rapidly evolving medical device landscape, the demands for innovation, precision, and regulatory compliance are greater than ever. Demax stands as a leader in the field of Medical Product ODM, offering a wide range of services, from precision tubing and guide wires to intelligent manufacturing and injection molding. By providing customized, high-quality solutions and fostering strategic partnerships, Demax ensures that medical companies can bring their products to market efficiently and with confidence.

If you’re looking for a trusted Medical Product ODM partner for your next medical innovation, Demax is ready to help turn your concept into reality. Reach out to Demax today to request a quote and take the first step toward your next medical breakthrough.