When was the last time you thought about what enables precise, life-saving navigation through delicate blood vessels during complex medical procedures? The answer may surprise you: it’s a tool as thin as a thread and as flexible as memory. Enter the world of the hydrophilic guidewire, a revolutionary advancement in medical technology that provides healthcare professionals with the ability to access even the most challenging pathways in the body with ease and accuracy.

In this blog, we’ll explore the structure, advantages, and market status of hydrophilic guidewires, examining why they have become indispensable in medical procedures like angioplasty, stenting, and urologic interventions.

Understanding Hydrophilic Guidewires: What They Are and How They Work

What is a Hydrophilic Guidewire?

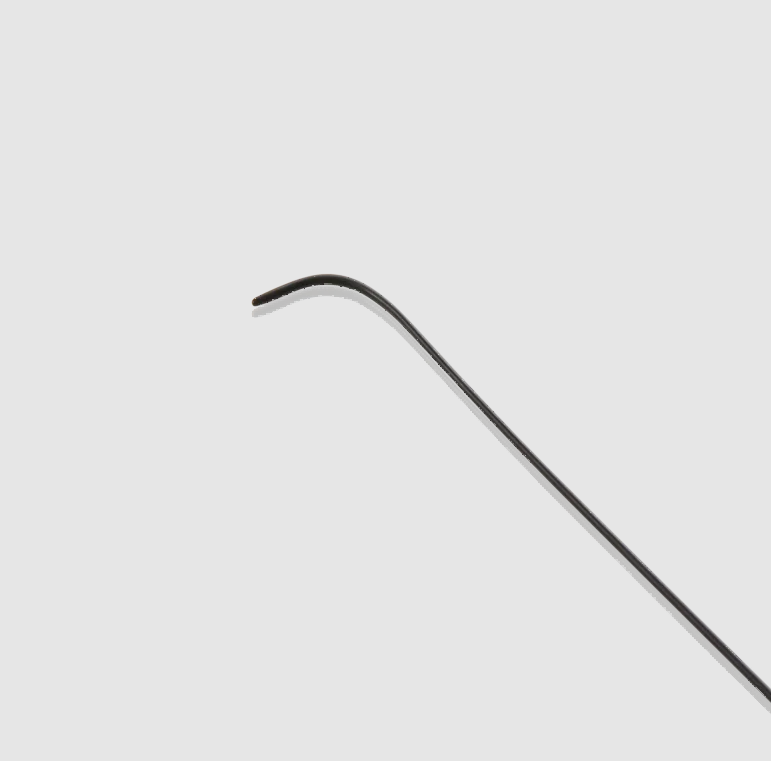

A hydrophilic guidewire is a thin, flexible medical device coated with a specialized hydrophilic polymer. This coating attracts and retains water, creating a smooth and lubricious surface that allows the guidewire to glide effortlessly through blood vessels. This ease of movement reduces friction against the vessel walls, minimizing the risk of damage during intricate medical procedures.

Composition and Design: What Makes It So Effective?

Hydrophilic guidewires are engineered with precision to balance strength, flexibility, and glide. Here’s a closer look at its typical components:

Core Material: These guidewires are often made with a core of stainless steel or nitinol, each offering unique benefits. Stainless steel provides necessary rigidity and durability, while nitinol—a shape-memory alloy—adds flexibility and elasticity, allowing the guidewire to navigate the complex anatomy of blood vessels without compromising its structural integrity.

Hydrophilic Coating: The hydrophilic coating is usually made of a material like PTFE, known for its lubricious properties. This coating activates upon contact with bodily fluids, creating a slippery surface that enhances the guidewire’s navigational ease. This layer is essential in minimizing friction and making the guidewire highly maneuverable even in complex or narrow pathways.

Radiopaque Marker: To enhance visibility during procedures, hydrophilic guidewires often include a radiopaque marker at the distal end, which allows medical professionals to precisely position the guidewire under imaging techniques like fluoroscopy. This feature helps prevent misplacement and increases accuracy.

Applications of Hydrophilic Guidewires in Medical Procedures

Hydrophilic guidewires are indispensable in numerous medical fields:

Angioplasty and Stenting: Used to navigate the coronary arteries, hydrophilic guidewires allow for accurate placement of stents, reducing the risk of arterial injury.

Urologic Procedures: These guidewires help in navigating the urinary tract, ensuring smooth access without harming sensitive tissues.

Peripheral Vascular Interventions: With options for various tip shapes—straight, angled, or J-tip—hydrophilic guidewires can accommodate the unique contours of peripheral vessels.

With multiple lengths and diameters available, they offer flexibility and adaptability for a wide range of clinical requirements.

The Market Status of Hydrophilic Guidewires: Current Trends and Future Outlook

Market Size and Growth Rate

By 2023, driven by growing demand for minimally invasive surgeries and innovations in guidewire technology. The global hydrophilic guidewire market is booming. According to recent reports, the market size was valued at approximately USD 1.2 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 6.5% through the forecast period. This growth is primarily fueled by advancements in healthcare infrastructure, an aging population, and rising cases of cardiovascular diseases that necessitate precise vascular interventions.

Future Projections

By 2030, the market for hydrophilic guidewires is anticipated to reach USD 2 billion. The expanding applications of these guidewires in cardiovascular, urological, and peripheral vascular procedures will continue to drive growth. Moreover, regions such as Asia-Pacific, especially China and India, are likely to witness the highest growth due to increasing investments in healthcare and rising awareness of minimally invasive procedures.

Key Features of Hydrophilic Guidewires

Hydrophilic Coating

The hydrophilic coating on these guidewires is designed to activate upon contact with bodily fluids, making the wire incredibly slippery. This smooth, lubricious surface minimizes friction, allowing the guidewire to glide through vessels and navigate challenging anatomical structures. This coating is also manufactured with meticulous attention to detail, ensuring that it maintains uniformity and durability throughout the procedure.

High Flexibility

Thanks to their flexible core materials—such as nitinol or stainless steel—hydrophilic guidewires offer an ideal balance of support and flexibility. This feature enables healthcare professionals to maneuver the guidewire with precision, even in highly curved or tortuous vessels, which are common in complex vascular structures.

Radiopaque Marker

Positioned at the distal end, the radiopaque marker enhances visibility during procedures, allowing clinicians to precisely monitor and position the guidewire. This feature is particularly beneficial in critical interventions where accurate placement is paramount to patient safety.

Multiple Length Options and Tapered Tip

Available in various lengths, hydrophilic guidewires cater to diverse procedural needs, from coronary interventions to urological procedures. The tapered tip design ensures smooth entry into vessels, reducing trauma to delicate tissues and further supporting patient safety.

Quality and Precision Manufacturing: Setting New Standards

Commitment to Quality: From R&D to Production

Manufacturers like Tianjin Dimax Medical Technology Co., Ltd. As a well-known supplier of hydrophilic guidewires, Tianjin Dimaco has always been committed to quality and innovation, relying on a team of experts in the fields of biology, material science, mechanics and other fields. Developed advanced R&D equipment to enhance technology and quality advantages.

Comprehensive Production Process

Tianjin Demax employs a range of production techniques—automation, semi-automation, and traditional methods—to ensure high-quality output. By integrating cutting-edge equipment with real-time production data, the company is able to optimize manufacturing processes and guarantee consistent quality across its product lines.

Quality Management and Certifications

The company strictly adheres to ISO9001 and ISO13485 certifications to establish a medical device quality management system. They monitor every stage of production and maintain strict quality standards. From coating application to bonding and testing, they pay attention to every technical detail. They ensure that every guidewire produced meets the highest standards.

Tianjin Demax Medical Technology: Leading the Way in Hydrophilic Guidewires

As one of the top suppliers in the hydrophilic guidewire market, Tianjin Demax Medical Technology Co., Ltd. stands out for its dedication to product innovation, customer service, and timely delivery. With an experienced sales and after-sales support team, Tianjin Demax ensures prompt responses and seamless communication with clients worldwide. Their commitment to quality is evident in every aspect of their production, from material selection to final testing, setting a benchmark in the industry.

The company’s achievements in precision extrusion, hydrophilic coating, metal weaving, and other advanced technologies enable it to deliver products that exceed customer expectations. Moreover, Tianjin Demax’s state-of-the-art manufacturing capabilities have helped overcome technical bottlenecks and localize production for maximum efficiency.

Conclusion: The Future of Hydrophilic Guidewires in Healthcare

Hydrophilic guidewires play a vital role in modern medical procedures. They provide the precision, flexibility and safety required to navigate complex anatomical structures. As the global market for these devices continues to grow, fueled by technological advances and rising demand for minimally invasive procedures, manufacturers like Tianjin Demax Medical Technology Co., Ltd. are leading the way in innovation and quality.

The next few years will come as healthcare systems around the world adopt more minimally invasive techniques. Hydrophilic guidewires will continue to be at the forefront of medical innovation. These guidewires offer high flexibility, radiopaque visibility and advanced coating technology. Paving the way for safer, more efficient patient care.