Demax is dedicated to advancing medical technologies, with a focus on delivering top-tier medical devices in China. The company specializes in the research, development, production, and distribution of solutions for coronary artery interventions, neurointerventions, and peripheral interventions. Demax also offers customized PTFE tubes and catheters tailored for medical OEM needs, all manufactured to world-class standards. In addition, Demax provides intelligent manufacturing production lines and a variety of other services. This new product is a game-changer in the medical industry, bringing both innovation and superior quality. Interested in learning more about how Demax is revolutionizing the medical field with this new development? Let’s take a closer look!

What Are PTFE Tubes and Catheters?

Explanation of PTFE (Polytetrafluoroethylene) as a Material

PTFE is a type of plastic. It is commonly known as Teflon. PTFE is strong and resistant to heat. It is widely used in many industries. In medical devices, it is used for its special properties.

Benefits of PTFE for Medical Applications: Biocompatibility and Durability

PTFE is safe for the human body. It does not react with body tissues. This makes it biocompatible. Additionally, it is durable and can last a long time. It also resists corrosion, making it ideal for medical devices.

Key Differences Between Standard and Custom PTFE Solutions

Standard PTFE tubes and catheters are made to fit general needs. Custom PTFE solutions, however, are made to meet specific requirements. Customization allows better performance and fit for medical procedures.

Innovation in Medical OEM Solutions

Demax’s Focus on Innovation and Precision in Medical Manufacturing

Demax focuses on innovation in medical manufacturing. The company invests heavily in research and development (R&D). It has a 25,000-square-meter production facility. This facility includes clean rooms that meet high standards, ensuring quality. The R&D team plays a key role in creating advanced medical solutions.

How Custom PTFE Tubes and Catheters Enhance Medical Procedures

Custom PTFE tubes and catheters help improve medical procedures. They are designed to meet the specific needs of each procedure. This customization enhances their effectiveness and safety in medical treatments.

Meeting Specific Needs of Medical Equipment Manufacturers with Tailored Solutions

Demax works closely with medical equipment manufacturers. The company provides tailored solutions for each client. With over 10 years of experience in OEM and ODM, Demax offers expertise in meeting exact specifications. Their R&D team is large, accounting for 40% of the total staff. They have established strong partnerships with companies in Europe and America.

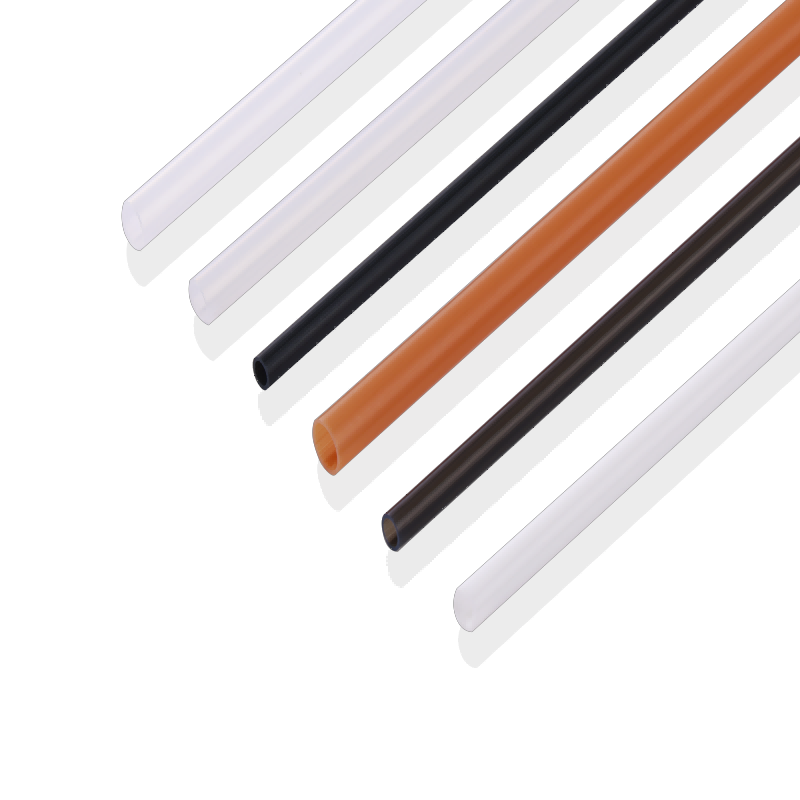

Features of Demax’s Custom PTFE Tubes

Supplied in Rolls for Continuous Production

Demax’s PTFE tubes are conveniently supplied in rolls, making them a practical choice for continuous production processes. This packaging method allows manufacturers to handle large quantities of tubes easily with minimal waste. Using rolls also streamlines the production process, ensuring a smoother, more efficient workflow. Furthermore, this method helps to lower manufacturing costs in later stages of production, as it reduces the need for frequent reloading or cutting of tubes. This cost-effective option makes Demax’s PTFE tubes a reliable solution for high-volume manufacturing.

Ultra-Thin Design for Lubricity

One of the standout features of Demax’s PTFE tubes is their ultra-thin design. This design improves the lubricity of the tubes, making them much smoother compared to standard alternatives. The smoother surface reduces friction, which helps minimize tissue damage and irritation during medical procedures. This is especially crucial in surgical and diagnostic applications, where minimizing harm to surrounding tissues is essential for patient safety. The enhanced lubricity also facilitates the smooth insertion and removal of medical instruments, improving the overall efficiency and safety of medical procedures.

Polymer-Coated for Durability

Demax’s PTFE tubes can be coated with advanced polymer materials, which offer additional benefits such as enhanced durability, longer shelf life, and better bonding strength. The polymer coating adds an extra layer of protection, making the tubes more resistant to wear and tear, as well as environmental factors that may affect their performance over time. This added durability makes them ideal for long-term use in medical applications. Additionally, the polymer coating improves the bonding effect when the tubes are used in conjunction with other materials, ensuring a stronger, more reliable connection in medical devices. The long shelf life of these tubes ensures that they remain in optimal condition, even after extended storage periods.

Applications in the Medical Field

Use in Surgery and Diagnostics

PTFE tubes have a wide range of applications in the medical field, especially in surgeries and diagnostic procedures. Due to their biocompatibility and strength, they are used in various surgical tools and patient care devices. For example, PTFE tubes are used in catheterization, where their smooth surface helps prevent clotting and ensures easy insertion. They are also integral in diagnostic equipment, providing accurate and reliable results. The versatility of PTFE tubes makes them indispensable in modern medicine, as they help ensure the safety and success of numerous medical procedures.

Integration into Medical Instruments

Demax’s PTFE tubes are commonly integrated into medical instruments, such as catheters, tubes, and other specialized tools. By incorporating PTFE into these devices, manufacturers can improve their functionality and safety. The low friction and high durability of PTFE ensure that medical instruments perform effectively during use, reducing the chances of malfunction or injury. The flexibility and strength of PTFE also make it an ideal material for applications where precision and reliability are critical. In this way, PTFE tubes not only improve the performance of medical instruments but also enhance the overall safety of patients undergoing treatment.

Supporting Minimally Invasive Surgeries

One of the key advantages of PTFE tubes is their support for minimally invasive surgeries (MIS). These surgeries, which are less intrusive than traditional methods, rely on the use of small incisions and specialized instruments to reduce patient recovery time and risk. PTFE tubes play a crucial role in these procedures, providing a smooth, flexible, and biocompatible option that helps guide instruments into place with minimal disruption to surrounding tissues. Their resistance to wear and corrosion ensures that they remain effective and safe over time, supporting innovations in MIS techniques that make surgeries safer, less painful, and more efficient.

Customization Process for OEMs

Custom Solutions for OEMs

Demax specializes in designing custom PTFE solutions for Original Equipment Manufacturers (OEMs). They understand that every OEM has unique needs and requirements, so they tailor their products to meet those specifications. By offering customization options, Demax ensures that each client receives a product that suits their specific application, improving both performance and efficiency. This flexibility makes Demax an ideal partner for companies looking to develop specialized medical devices or instruments.

Collaborative Design Process

Demax takes a collaborative approach to the design process with its clients. From the initial concept to the final product, Demax works closely with manufacturers to ensure that every detail is accounted for.

Looking for the Best in Custom PTFE Tubes?

Contact Demax today to explore our range of custom PTFE tubes and catheters tailored to your requirements. Our team is ready to assist you with product selection and design.