PEEK and FEP tubes are increasingly popular in modern engineering due to their strength and reliability. PEEK is known for its exceptional durability and high-temperature resistance, while FEP is valued for its chemical resistance and flexibility. These outstanding properties make them ideal for industries such as medical, aerospace, and automotive. Demax is a trusted manufacturer of these tubes, renowned for delivering high-quality products. The company is certified as a national high-tech enterprise and holds a national enterprise technology center certification, underscoring its commitment to innovation and excellence. If you’re seeking dependable PEEK and FEP tubes, Demax is an excellent choice. Want to learn more about how Demax can meet your needs? Keep reading!

Exceptional Durability in Harsh Environments

PEEK and FEP Tubes are Highly Resistant to High Temperatures and Chemicals

PEEK and FEP tubes are strong and durable. They resist high temperatures and harsh chemicals. This makes them ideal for tough environments. These materials do not break down easily. They can handle extreme conditions that other materials cannot.

Ideal for Extreme Industrial and Aerospace Applications

PEEK and FEP tubes are perfect for industrial and aerospace use. They can survive the challenges of these fields. The tubes withstand heat, chemicals, and pressure. This makes them reliable in demanding applications like machinery and spacecraft.

Demax’s PEEK and FEP Tubes Provide Enhanced Durability for Long-Lasting Solutions

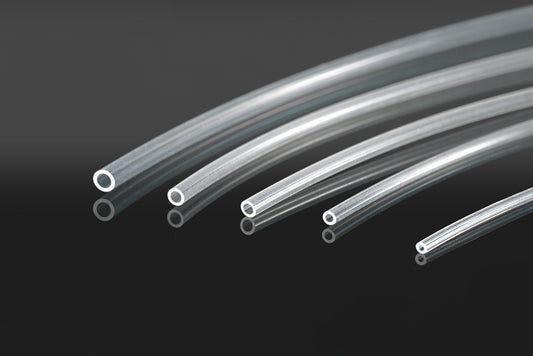

Demax’s PEEK and FEP tubes are designed for long-lasting use. They provide strong solutions for various industries. Demax offers FEP heat shrink tubing with a lower heat shrink temperature compared to PTFE and FEP. FEP tubing also has better flexibility, light transmittance, and lubricity than FEP. Demax offers shrink ratios of 1.3:1 to 1.8:1. The recommended shrinking temperature is 200°C-280°C. The time and temperature may vary depending on the design.

High-Performance in Medical

Application Fields in Medical

PEEK and FEP tubes are used in many medical applications. These include welding guiding catheters, angiography catheters, micro catheters, guiding sheaths, and distal access catheters. Different welding methods are used, including laser welding, hot air welding, and heat fusion welding. These tubes provide reliable and safe solutions for medical procedures.

Demax Offers High-Performance PEEK and FEP Tubes

Demax offers high-performance PEEK and FEP tubes designed for medical use. These tubes have specific measurements, including a minimum inner diameter before shrinkage of 0.79~12 mm and a maximum inner diameter before shrinkage of 0.69~6.67 mm. After shrinkage, the wall thickness varies from 0.2~0.48mm±0.05. The recommended shrink temperature is between 200~280°C with shrink ratios of1.3:1 ~ 1.8:1. The tubes have a concentricity of ≥90% and meet ISO 10993 biocompatibility standards. Demax’s tubes provide excellent performance and reliability in medical devices.

Precision Engineering for Complex Systems

PEEK and FEP Tubes are Perfect for Precision Manufacturing

PEEK and FEP tubes are ideal for precision manufacturing. These materials offer high accuracy and reliability. They are used to create parts that require tight tolerances. These tubes can be shaped to fit exact specifications. Their stability makes them suitable for complex systems.

Provide Stability and Consistency in Critical Systems Like Medical Devices

PEEK and FEP tubes offer stability. They ensure consistent performance in critical systems. This is especially important for medical devices. These tubes can handle the stress and pressure of medical procedures. Their reliability is key to preventing failures in sensitive environments. Medical professionals trust them for their precision.

Demax Customizes Tube Solutions for Specialized Engineering Requirements

Demax provides customized tube solutions. We can adapt to specific engineering needs. Our team works closely with clients to design the right solution. Demax welcomes OEM projects. With nearly 10 years of OEM experience, we are experts in creating tailored solutions. The Demax R&D team accounts for 16% of the company’s workforce. This team works on developing the best possible products. Demax has built strong OEM partnerships with international companies. If you need a quote, Demax is ready to help. You can contact us at info@tj-demaxmedical.com.

Corrosion and Chemical Resistance

FEP Tubes Resist Most Acids, Bases, and Solvents

FEP tubes are highly resistant to many harsh chemicals. They can withstand most acids, bases, and solvents. This makes them ideal for use in environments where chemicals are present. Their corrosion resistance ensures long-lasting performance in challenging conditions.

PEEK’s Resistance to Aggressive Chemicals Ensures Longevity

PEEK is known for its resistance to aggressive chemicals. This property helps extend the life of products made from it. PEEK tubes can handle extreme conditions that would damage other materials. This makes PEEK an excellent choice for critical applications.

Demax’s Manufacturing Processes Guarantee the Highest Levels of Chemical Resistance

Demax’s manufacturing processes are designed to ensure the highest chemical resistance. Our methods guarantee that PEEK and FEP tubes perform well even in tough conditions. Demax uses strict quality control to ensure the tubes are reliable and durable. Our products meet the highest industry standards for chemical resistance.

Demax’s PEEK and FEP Tubes: Premium Solutions for Demanding Applications

Demax’s PEEK and FEP tubes are known for their strength and dependability, these tubes deliver exceptional results. PEEK tubes are highly resistant to extreme temperatures and harsh chemicals, while FEP tubes provide excellent flexibility and chemical resistance. We offer customized solutions to meet your specific requirements, ensuring top-notch quality and consistent performance. For durable and reliable tubing, Demax is the ideal partner. Reach out today for a quote and discover how our products can benefit your business.