Product

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Home

- /

- Products

Design

The Demax mold design team has lots of experience making molds for medical devices. We use software like NX, Autocad, and Moldflow to help customers with their special needs. We optimize product designs for injection-molded parts, design molds, and improve the injection molding process. This helps reduce the number of adjustments needed for the molds and products, making the whole process faster. It also helps us check the molds and injection molding process quickly, so we can fix any problems sooner. This speeds up the whole mold development process and increases the number of good parts we can make.

Disposable Guidewire For Digestive Tract And Airway

The Demax Disposable Guidewire for Digestive Tract and Airway is a state-of-the-art medical device engineered to aid healthcare professionals in navigating endoscopic instruments through complex anatomical structures with precision and ease. Crafted with meticulous attention to detail and utilizing cutting-edge materials, this disposable guidewire ensures exceptional performance and patient safety.

Disposable Pressure Transducer

Features:

1.High-quality pressure electronic chip

2.Rich specifications and models

3.The tube wall is solid and kink-resistantwhile reducing signal attenuationDisposable Urinary Guidewire

The Disposable Urinary Guidewire by Demax is constructed using high-quality materials to ensure optimal performance and patient comfort. It features a core structure made of Nitinol alloy, providing excellent flexibility and durability for navigating through the urinary tract. The guidewire is coated with a hydrophilic layer, ensuring smooth passage through the urethra and urinary system. Additionally, radiopaque markers are strategically placed along the length of the guidewire for enhanced visibility under fluoroscopy, aiding in accurate positioning during procedures.

Disposable Urinary Zebra Guidewire

The Disposable Urinary Zebra Guidewire by Demax is meticulously crafted using top-quality materials to ensure optimal performance and patient safety. It comprises a core structure made of high-strength Nitinol alloy, providing exceptional flexibility and durability for navigating through the urinary tract with precision. This core is coated with a hydrophilic layer, ensuring smooth passage through the urethra and urinary system. The guidewire also features radiopaque markers strategically placed along its length, enhancing visibility under fluoroscopy for accurate positioning during procedures.

ETFE Tube

ETFE tubes manufactured by Demax are crafted from high-quality ethylene tetrafluoroethylene (ETFE) polymer.

This fluoropolymer material offers exceptional chemical resistance, mechanical strength, and biocompatibility, making it ideal for medical device applications.

ETFE tubes undergo precise extrusion processes to achieve consistent dimensions, smooth surfaces, and reliable performance in medical settings.

Extra Stiff Guidewire

The Demax Extra Stiff Guidewire is meticulously crafted from high-quality materials to ensure exceptional performance and reliability. Composed of a PTFE-coated stainless steel core wire and a PTFE-coated spring, this guide wire offers optimal strength, flexibility, and maneuverability for navigating through challenging anatomical structures with ease. Additionally, some models feature a radiopaque spring, enhancing visibility under fluoroscopy for precise positioning within the target area. This advanced composition guarantees superior durability, biocompatibility, and performance, making the Demax Extra Stiff Guidewire an indispensable tool for healthcare professionals in various medical procedures.

FEP Heat Shrink Tube

The FEP Heat Shrink Tube boasts a composition rooted in fluorinated ethylene propylene (FEP), a thermoplastic polymer renowned for its exceptional properties in medical applications.

FEP exhibits a unique combination of characteristics that make it ideally suited for medical tubing. Its molecular structure imparts remarkable clarity to the tubing, allowing for optimal visualization of fluids and instruments during medical procedures, essential for accurate monitoring and precise manipulation.

Flaring

Precision Medical Tubing Services Flaring involves the precise modification of medical-grade tubing materials to create flares and expansions. The composition of the tubing used in this process varies depending on the specific requirements of the medical device and the application. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

Guidewire Welding

The composition of guidewire assemblies produced by Demax is meticulously crafted to ensure superior performance and reliability. These assemblies typically consist of high-quality materials such as stainless steel, nitinol, or specialty alloys, chosen for their mechanical strength, corrosion resistance, and biocompatibility where applicable, particularly in medical applications. Additionally, advanced welding techniques, including plasma welding, laser welding, and PTCA wire brazing, are employed to securely fuse the components together.

Guiding Catheter

Guiding catheters are typically composed of biocompatible materials such as polyurethane or nylon, chosen for their flexibility, durability, and compatibility with bodily tissues. The catheter shaft is reinforced with braided or coiled wires to provide structural support and torqueability while maintaining flexibility for navigation through tortuous vascular anatomy. Soft, atraumatic tips minimize trauma to blood vessels during insertion and positioning. Radiopaque markers or bands incorporated into the catheter shaft enhance visibility under fluoroscopy or other imaging modalities, allowing for precise navigation and positioning during procedures. Demax’s guiding catheters are engineered with advanced materials and design features to optimize performance and safety, ensuring successful outcomes in a wide range of interventional procedures.

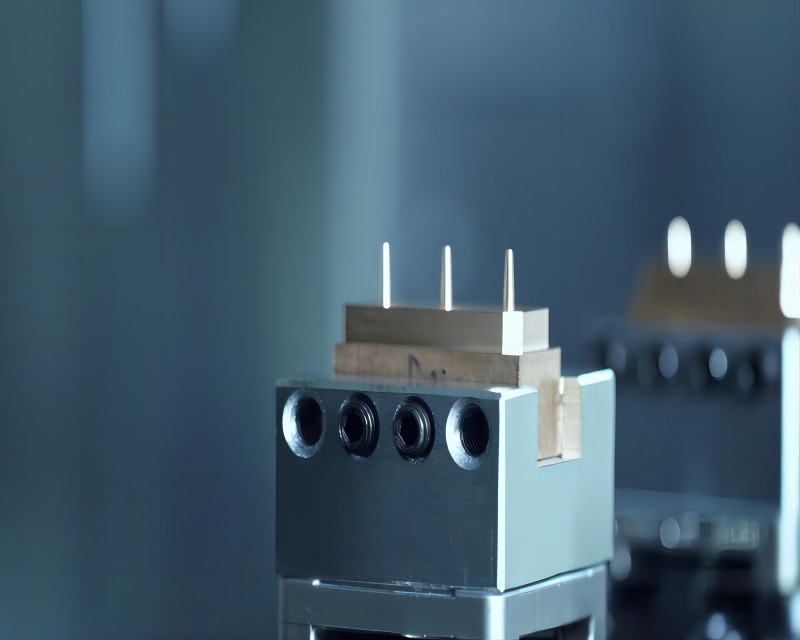

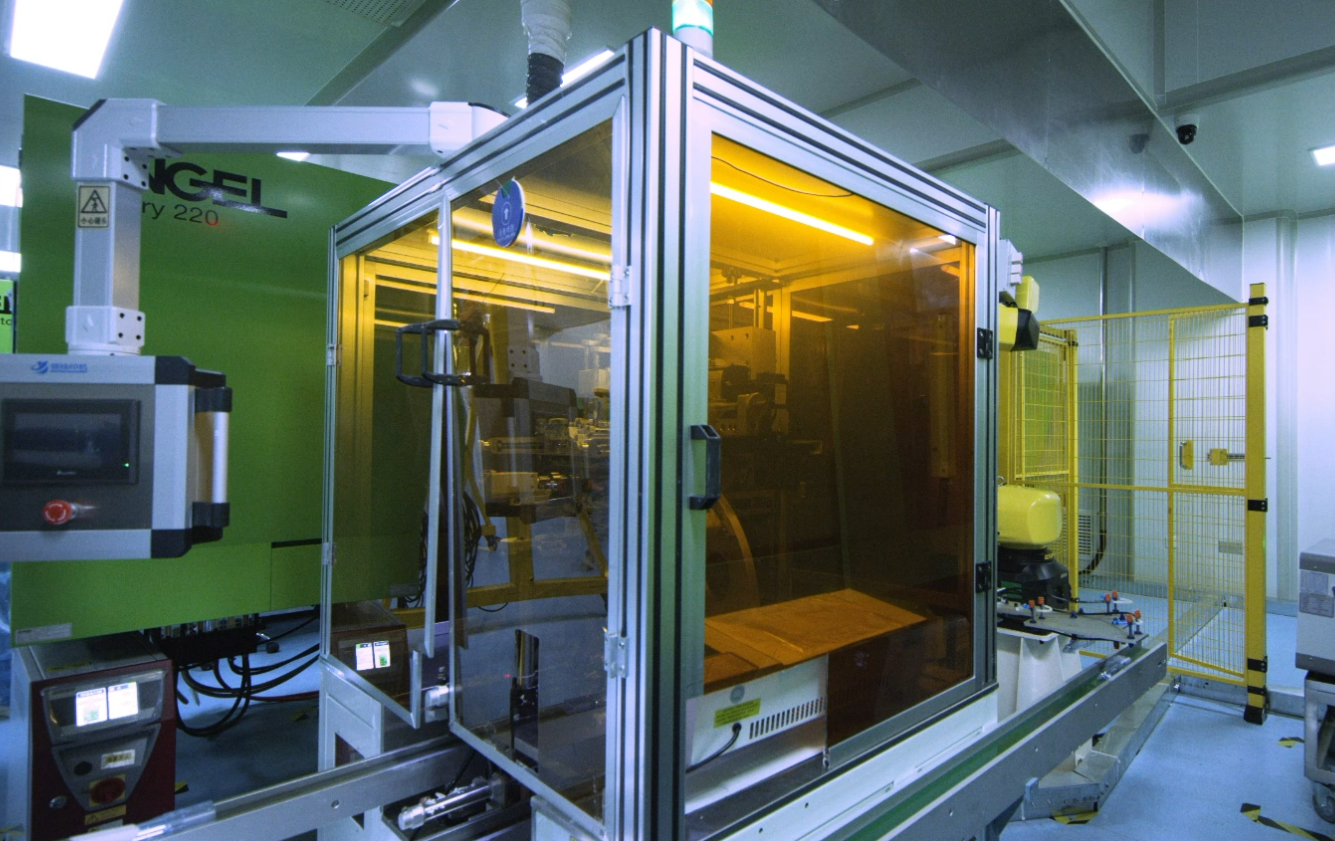

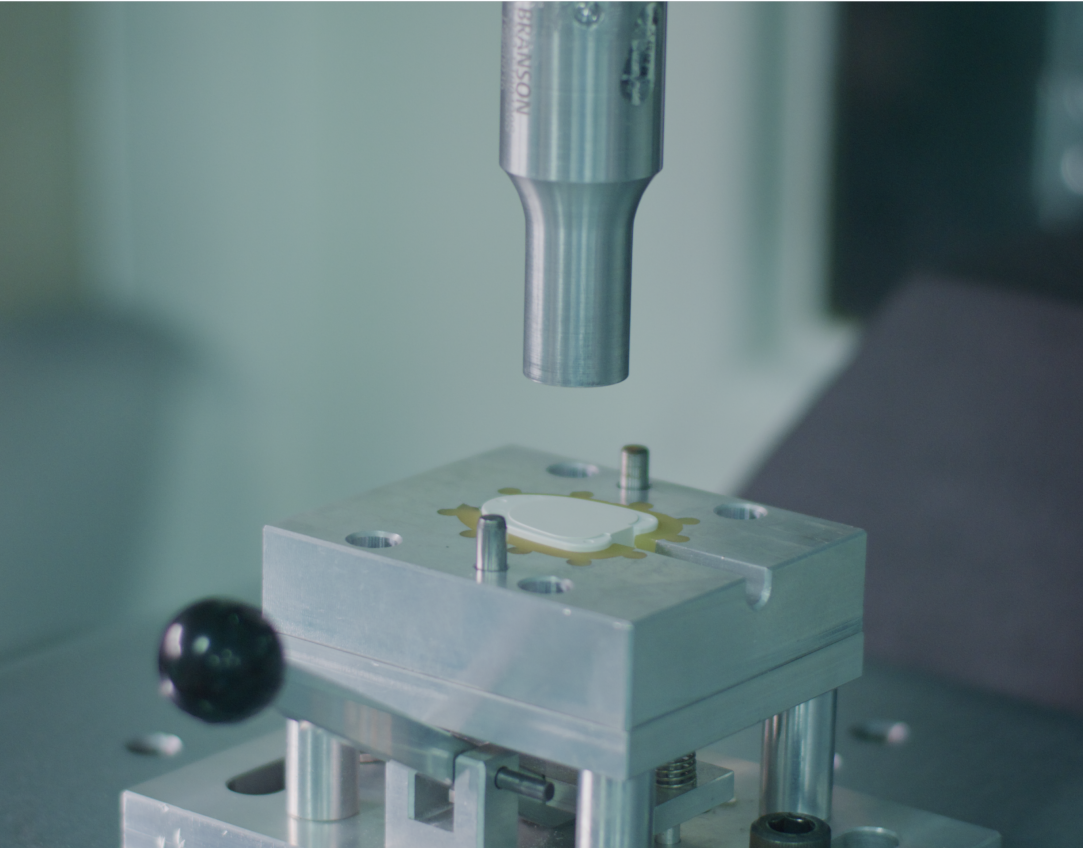

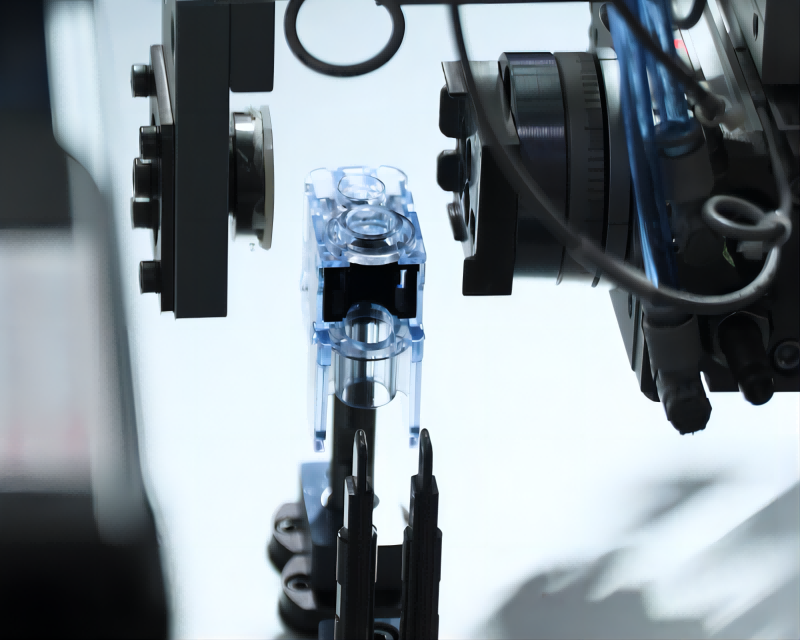

High precision injection molded parts

Demax boasts state-of-the-art injection molding facilities, including 100,000 and 10,000-level dust-free workshops, ensuring a pristine manufacturing environment conducive to producing high-quality precision parts. Within these workshops, Demax utilizes top-of-the-line injection molding machines from renowned brands such as Engel and Sumitomo. These machines, with tonnage ranging from 80T to 220T, cover a wide spectrum of capabilities, including vertical and horizontal configurations, as well as hydraulic and electric injection molding technologies.

Design

The Demax mold design team has lots of experience making molds for medical devices. We use software like NX, Autocad, and Moldflow to help customers with their special needs. We optimize product designs for injection-molded parts, design molds, and improve the injection molding process. This helps reduce the number of adjustments needed for the molds and products, making the whole process faster. It also helps us check the molds and injection molding process quickly, so we can fix any problems sooner. This speeds up the whole mold development process and increases the number of good parts we can make.

Disposable Guidewire For Digestive Tract And Airway

The Demax Disposable Guidewire for Digestive Tract and Airway is a state-of-the-art medical device engineered to aid healthcare professionals in navigating endoscopic instruments through complex anatomical structures with precision and ease. Crafted with meticulous attention to detail and utilizing cutting-edge materials, this disposable guidewire ensures exceptional performance and patient safety.

Disposable Pressure Transducer

Features:

1.High-quality pressure electronic chip

2.Rich specifications and models

3.The tube wall is solid and kink-resistantwhile reducing signal attenuationDisposable Urinary Guidewire

The Disposable Urinary Guidewire by Demax is constructed using high-quality materials to ensure optimal performance and patient comfort. It features a core structure made of Nitinol alloy, providing excellent flexibility and durability for navigating through the urinary tract. The guidewire is coated with a hydrophilic layer, ensuring smooth passage through the urethra and urinary system. Additionally, radiopaque markers are strategically placed along the length of the guidewire for enhanced visibility under fluoroscopy, aiding in accurate positioning during procedures.

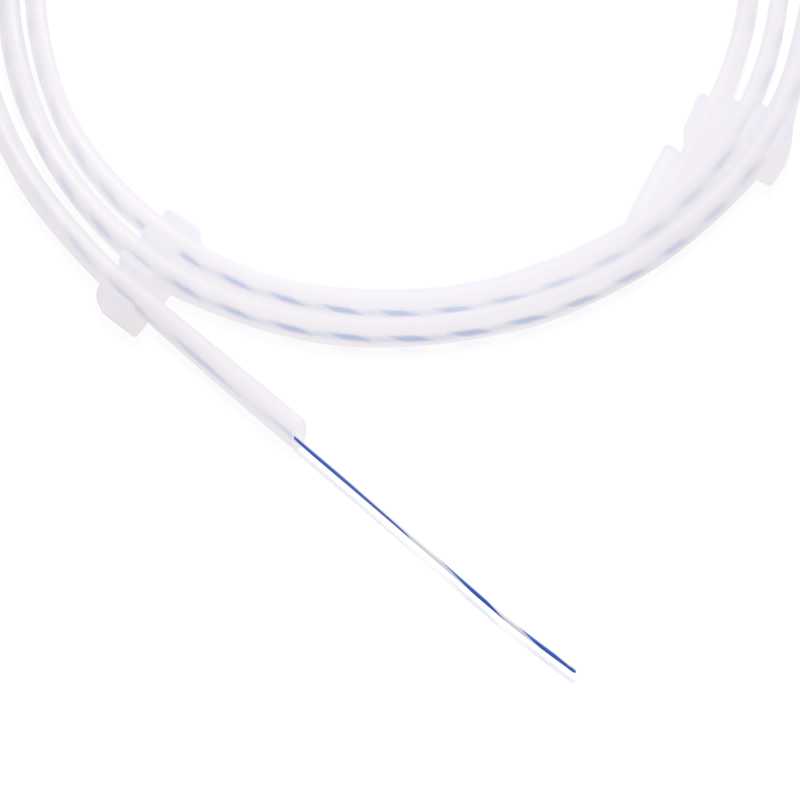

Disposable Urinary Zebra Guidewire

The Disposable Urinary Zebra Guidewire by Demax is meticulously crafted using top-quality materials to ensure optimal performance and patient safety. It comprises a core structure made of high-strength Nitinol alloy, providing exceptional flexibility and durability for navigating through the urinary tract with precision. This core is coated with a hydrophilic layer, ensuring smooth passage through the urethra and urinary system. The guidewire also features radiopaque markers strategically placed along its length, enhancing visibility under fluoroscopy for accurate positioning during procedures.

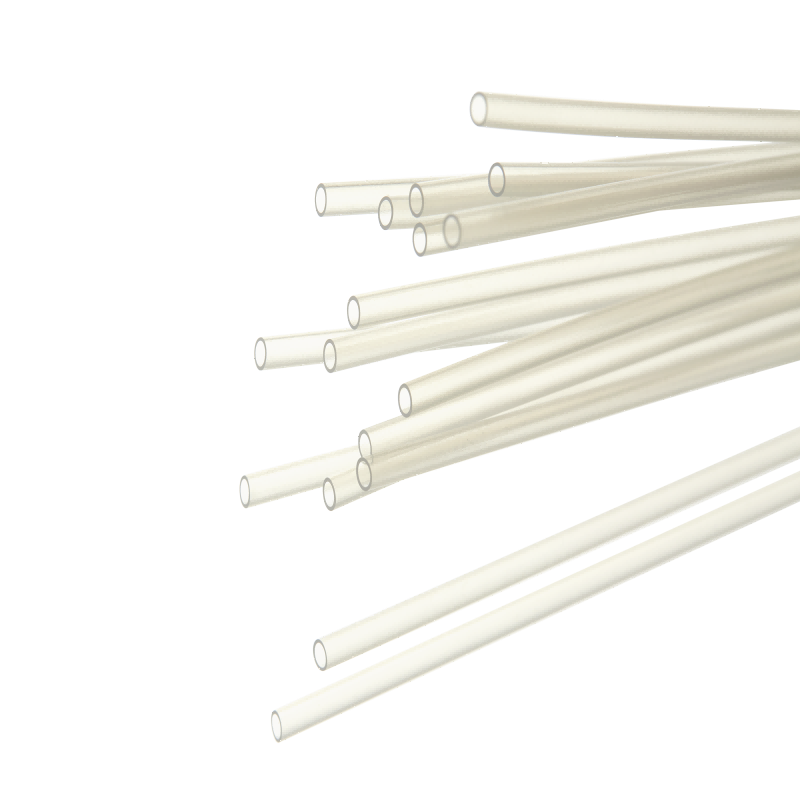

ETFE Tube

ETFE tubes manufactured by Demax are crafted from high-quality ethylene tetrafluoroethylene (ETFE) polymer.

This fluoropolymer material offers exceptional chemical resistance, mechanical strength, and biocompatibility, making it ideal for medical device applications.

ETFE tubes undergo precise extrusion processes to achieve consistent dimensions, smooth surfaces, and reliable performance in medical settings.

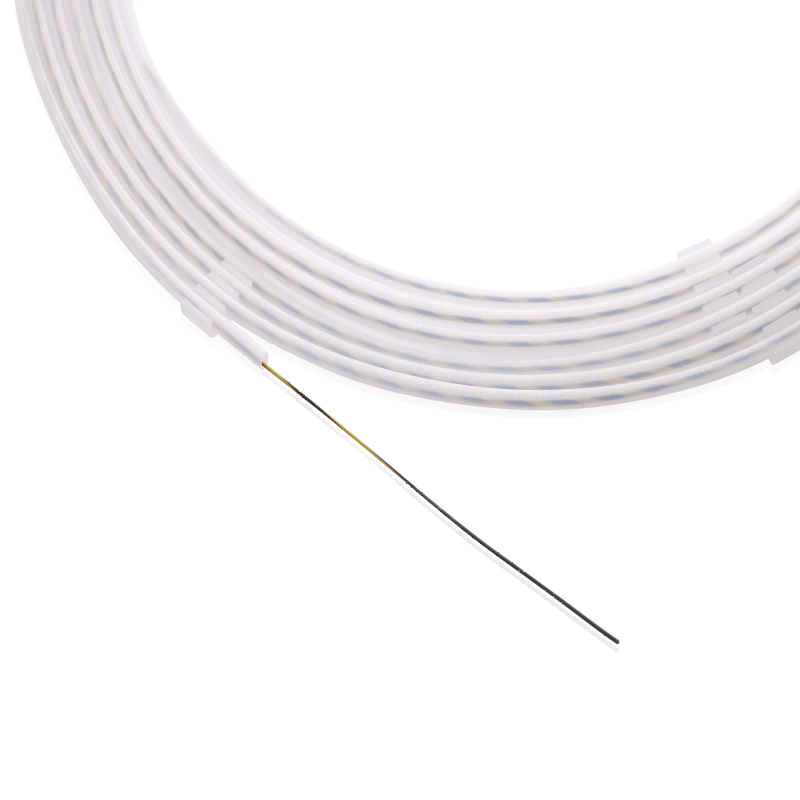

Extra Stiff Guidewire

The Demax Extra Stiff Guidewire is meticulously crafted from high-quality materials to ensure exceptional performance and reliability. Composed of a PTFE-coated stainless steel core wire and a PTFE-coated spring, this guide wire offers optimal strength, flexibility, and maneuverability for navigating through challenging anatomical structures with ease. Additionally, some models feature a radiopaque spring, enhancing visibility under fluoroscopy for precise positioning within the target area. This advanced composition guarantees superior durability, biocompatibility, and performance, making the Demax Extra Stiff Guidewire an indispensable tool for healthcare professionals in various medical procedures.

FEP Heat Shrink Tube

The FEP Heat Shrink Tube boasts a composition rooted in fluorinated ethylene propylene (FEP), a thermoplastic polymer renowned for its exceptional properties in medical applications.

FEP exhibits a unique combination of characteristics that make it ideally suited for medical tubing. Its molecular structure imparts remarkable clarity to the tubing, allowing for optimal visualization of fluids and instruments during medical procedures, essential for accurate monitoring and precise manipulation.

Flaring

Precision Medical Tubing Services Flaring involves the precise modification of medical-grade tubing materials to create flares and expansions. The composition of the tubing used in this process varies depending on the specific requirements of the medical device and the application. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

Guidewire Welding

The composition of guidewire assemblies produced by Demax is meticulously crafted to ensure superior performance and reliability. These assemblies typically consist of high-quality materials such as stainless steel, nitinol, or specialty alloys, chosen for their mechanical strength, corrosion resistance, and biocompatibility where applicable, particularly in medical applications. Additionally, advanced welding techniques, including plasma welding, laser welding, and PTCA wire brazing, are employed to securely fuse the components together.

Guiding Catheter

Guiding catheters are typically composed of biocompatible materials such as polyurethane or nylon, chosen for their flexibility, durability, and compatibility with bodily tissues. The catheter shaft is reinforced with braided or coiled wires to provide structural support and torqueability while maintaining flexibility for navigation through tortuous vascular anatomy. Soft, atraumatic tips minimize trauma to blood vessels during insertion and positioning. Radiopaque markers or bands incorporated into the catheter shaft enhance visibility under fluoroscopy or other imaging modalities, allowing for precise navigation and positioning during procedures. Demax’s guiding catheters are engineered with advanced materials and design features to optimize performance and safety, ensuring successful outcomes in a wide range of interventional procedures.

High precision injection molded parts

Demax boasts state-of-the-art injection molding facilities, including 100,000 and 10,000-level dust-free workshops, ensuring a pristine manufacturing environment conducive to producing high-quality precision parts. Within these workshops, Demax utilizes top-of-the-line injection molding machines from renowned brands such as Engel and Sumitomo. These machines, with tonnage ranging from 80T to 220T, cover a wide spectrum of capabilities, including vertical and horizontal configurations, as well as hydraulic and electric injection molding technologies.