Product

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Home

- /

- Products

-

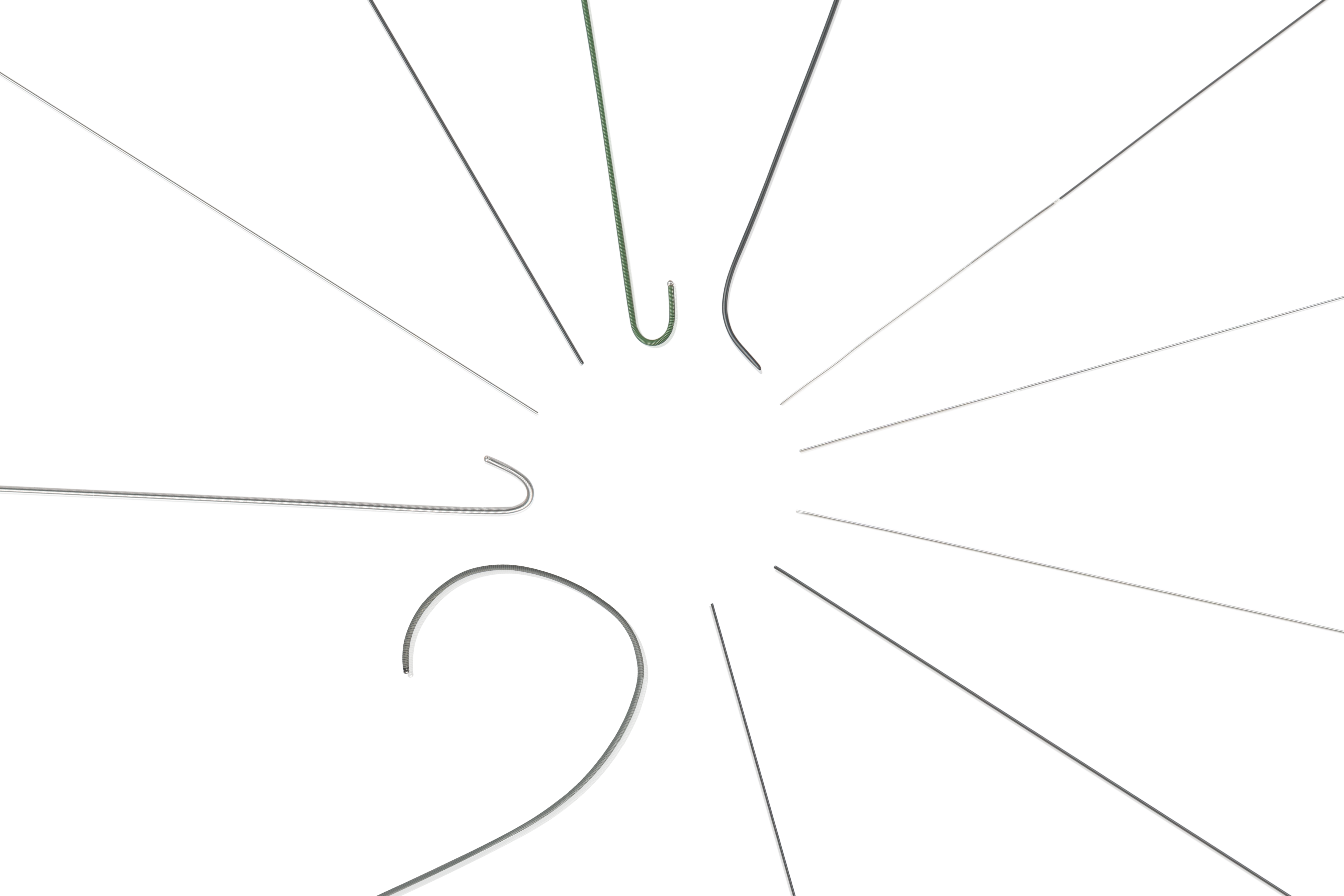

Hook Forming

Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, chosen for their exceptional mechanical properties, corrosion resistance, and biocompatibility. These materials undergo precise shaping processes to achieve intricate hook configurations tailored to specific medical device applications. With our commitment to quality and precision, Demax ensures that hook-formed components meet the rigorous demands of medical device manufacturing, contributing to the advancement of healthcare worldwide.

-

Hydrophilic Guidewire

The composition of Hydrophilic Coated Guidewires typically consists of a core material, such as stainless steel or nitinol, surrounded by a hydrophilic polymer coating. Stainless steel provides the necessary rigidity and structural integrity to the guidewire, enabling it to withstand the forces encountered during navigation through the body. On the other hand, nitinol, a shape-memory alloy, offers flexibility and elasticity, allowing the guidewire to adapt to the contours of anatomical structures without sacrificing durability.

The hydrophilic coating, usually composed of PTFE or a similar material, serves as a lubricious layer that reduces friction and enhances the guidewire’s ability to glide smoothly through the vasculature or other bodily passages. This coating undergoes a specialized manufacturing process to ensure uniformity and durability, enabling the guidewire to maintain its hydrophilic properties throughout the duration of the procedure.

-

Laminating & Welding

The composition of Intelligent Manufacturing Production Equipment Laminating & Welding encompasses a combination of key components, including robotic arms or manipulators for precise material handling, advanced welding technologies such as laser or ultrasonic welding for high-speed and accurate bonding, sophisticated control systems for regulating process parameters, automatic material feeding and alignment systems for streamlined production, integrated quality inspection mechanisms for ensuring product quality, and customizable configurations to adapt to various materials and production requirements. Together, these components work in harmony to enable efficient and reliable lamination and welding processes, contributing to the production of high-quality products across diverse industries.

-

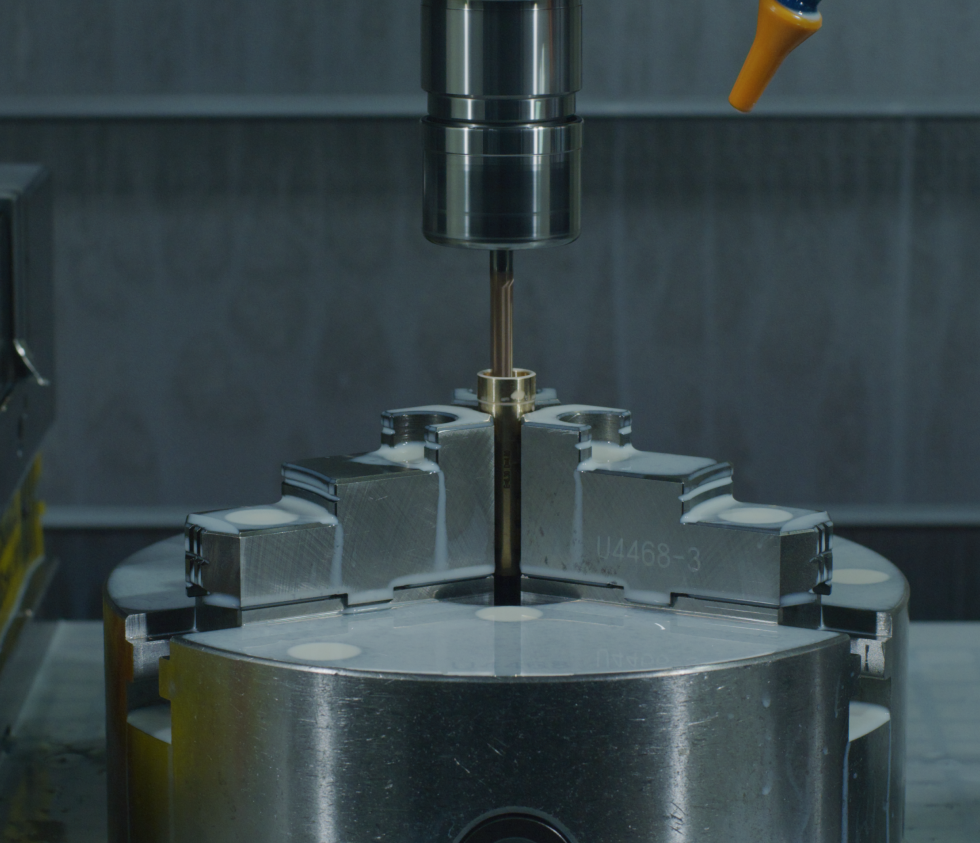

Manufacturing

Demax boasts a comprehensive array of equipment for precision injection mold manufacturing, featuring Japanese CNC machines, Japanese/Swiss precision EDM machines, Japanese wire cutting machines, Japanese NC lathes, and precision surface grinders. Our workshops are meticulously maintained with constant temperature and humidity control, fostering an optimal environment for mold production. With an advanced mold processing concept, coupled with German Zeiss three-coordinate inspection technology, we ensure unparalleled accuracy in mold fabrication. Additionally, our team comprises experienced technicians with over 10 years of expertise in processing medical injection mold parts, guaranteeing precision and reliability throughout the manufacturing process.

-

Microcatheter

Features:

1. PTFE inner layer allows for smooth passage for embolic agents;

2. Optimal trackability through tortuous anatomy;

3. Available in pre-shaped tip shape configurations for vessel engagement;

4. Four shapes provides more option for clinical usage;

5. 2.0F/2.2F/2.6F/2.8F models are available;

6. Hydrophilic coating technology, smoothly through the lesion. -

Movable-Core Guidewire

The Movable-Core Guidewire is composed of a flexible outer wire and a movable core, both typically made of materials such as stainless steel or nitinol. The outer wire provides support and flexibility for navigating through blood vessels, while the movable core allows for independent movement within the outer wire, providing precise control and maneuverability during procedures. Some wire guides may feature a hydrophilic coating to facilitate smooth advancement through the vasculature and reduce the risk of vessel trauma. Additionally, radiopaque markers on the wire guide enhance visibility under fluoroscopy, aiding in the accurate placement of catheters and other medical devices.

-

Nasogastric Tube Guidewire

The guidewire is coated with a super-lubricious hydrophilic coating, facilitating smooth advancement through the nasal passages, esophagus, and into the stomach. This coating reduces friction and minimizes the risk of tissue trauma during insertion. The guidewire features a soft and tapered tip design, making it easier to navigate through the nasal passages, esophagus, and into the stomach. This design ensures minimal patient discomfort and tissue trauma during the procedure.

-

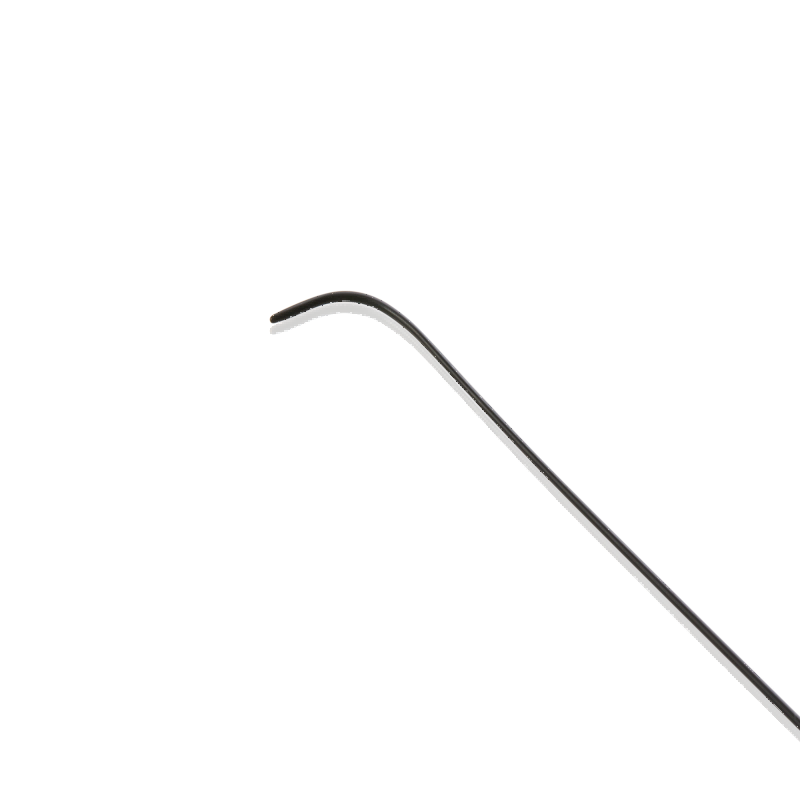

Neuro-Micro Guidewire

The Demax Neuro-Micro Guidewire is an advanced medical device specifically designed to assist healthcare professionals in navigating through intricate neurovascular structures with unparalleled precision and ease. Crafted with precision and utilizing cutting-edge materials, this disposable guidewire offers exceptional performance and patient safety, making it an indispensable tool for neurovascular procedures.

-

Hook Forming

Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, chosen for their exceptional mechanical properties, corrosion resistance, and biocompatibility. These materials undergo precise shaping processes to achieve intricate hook configurations tailored to specific medical device applications. With our commitment to quality and precision, Demax ensures that hook-formed components meet the rigorous demands of medical device manufacturing, contributing to the advancement of healthcare worldwide.

-

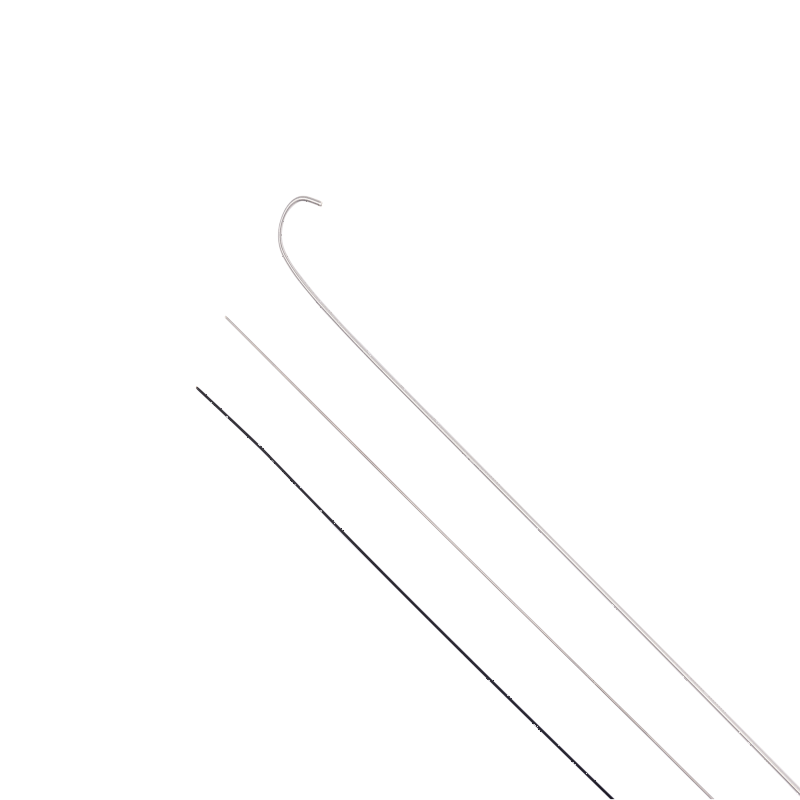

Hydrophilic Guidewire

The composition of Hydrophilic Coated Guidewires typically consists of a core material, such as stainless steel or nitinol, surrounded by a hydrophilic polymer coating. Stainless steel provides the necessary rigidity and structural integrity to the guidewire, enabling it to withstand the forces encountered during navigation through the body. On the other hand, nitinol, a shape-memory alloy, offers flexibility and elasticity, allowing the guidewire to adapt to the contours of anatomical structures without sacrificing durability.

The hydrophilic coating, usually composed of PTFE or a similar material, serves as a lubricious layer that reduces friction and enhances the guidewire’s ability to glide smoothly through the vasculature or other bodily passages. This coating undergoes a specialized manufacturing process to ensure uniformity and durability, enabling the guidewire to maintain its hydrophilic properties throughout the duration of the procedure.

-

Laminating & Welding

The composition of Intelligent Manufacturing Production Equipment Laminating & Welding encompasses a combination of key components, including robotic arms or manipulators for precise material handling, advanced welding technologies such as laser or ultrasonic welding for high-speed and accurate bonding, sophisticated control systems for regulating process parameters, automatic material feeding and alignment systems for streamlined production, integrated quality inspection mechanisms for ensuring product quality, and customizable configurations to adapt to various materials and production requirements. Together, these components work in harmony to enable efficient and reliable lamination and welding processes, contributing to the production of high-quality products across diverse industries.

-

Manufacturing

Demax boasts a comprehensive array of equipment for precision injection mold manufacturing, featuring Japanese CNC machines, Japanese/Swiss precision EDM machines, Japanese wire cutting machines, Japanese NC lathes, and precision surface grinders. Our workshops are meticulously maintained with constant temperature and humidity control, fostering an optimal environment for mold production. With an advanced mold processing concept, coupled with German Zeiss three-coordinate inspection technology, we ensure unparalleled accuracy in mold fabrication. Additionally, our team comprises experienced technicians with over 10 years of expertise in processing medical injection mold parts, guaranteeing precision and reliability throughout the manufacturing process.

-

Microcatheter

Features:

1. PTFE inner layer allows for smooth passage for embolic agents;

2. Optimal trackability through tortuous anatomy;

3. Available in pre-shaped tip shape configurations for vessel engagement;

4. Four shapes provides more option for clinical usage;

5. 2.0F/2.2F/2.6F/2.8F models are available;

6. Hydrophilic coating technology, smoothly through the lesion. -

Movable-Core Guidewire

The Movable-Core Guidewire is composed of a flexible outer wire and a movable core, both typically made of materials such as stainless steel or nitinol. The outer wire provides support and flexibility for navigating through blood vessels, while the movable core allows for independent movement within the outer wire, providing precise control and maneuverability during procedures. Some wire guides may feature a hydrophilic coating to facilitate smooth advancement through the vasculature and reduce the risk of vessel trauma. Additionally, radiopaque markers on the wire guide enhance visibility under fluoroscopy, aiding in the accurate placement of catheters and other medical devices.

-

Nasogastric Tube Guidewire

The guidewire is coated with a super-lubricious hydrophilic coating, facilitating smooth advancement through the nasal passages, esophagus, and into the stomach. This coating reduces friction and minimizes the risk of tissue trauma during insertion. The guidewire features a soft and tapered tip design, making it easier to navigate through the nasal passages, esophagus, and into the stomach. This design ensures minimal patient discomfort and tissue trauma during the procedure.

-

Neuro-Micro Guidewire

The Demax Neuro-Micro Guidewire is an advanced medical device specifically designed to assist healthcare professionals in navigating through intricate neurovascular structures with unparalleled precision and ease. Crafted with precision and utilizing cutting-edge materials, this disposable guidewire offers exceptional performance and patient safety, making it an indispensable tool for neurovascular procedures.

.png)