Product

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Home

- /

- Products

-

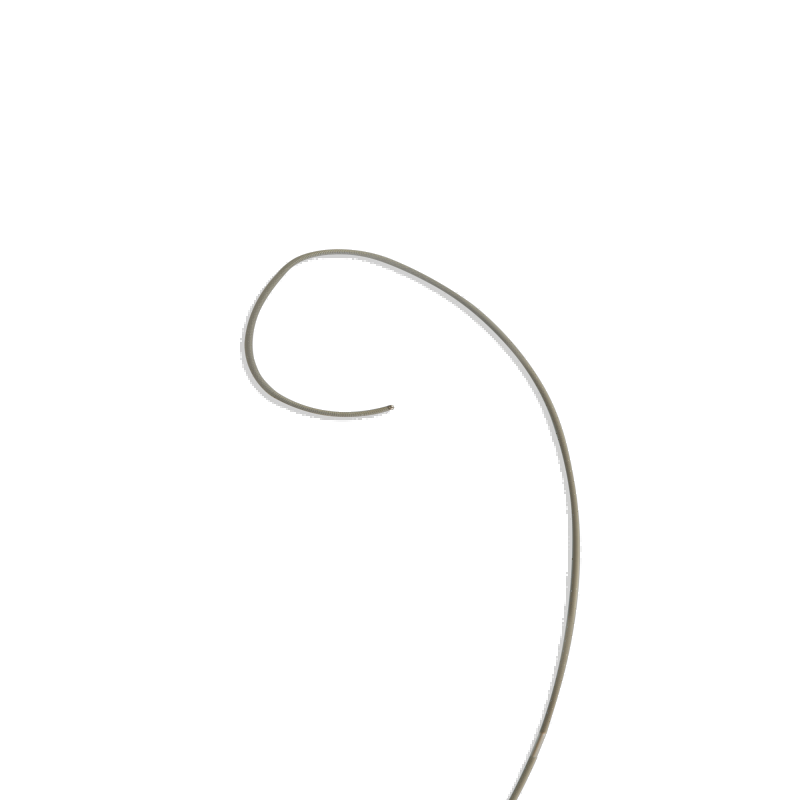

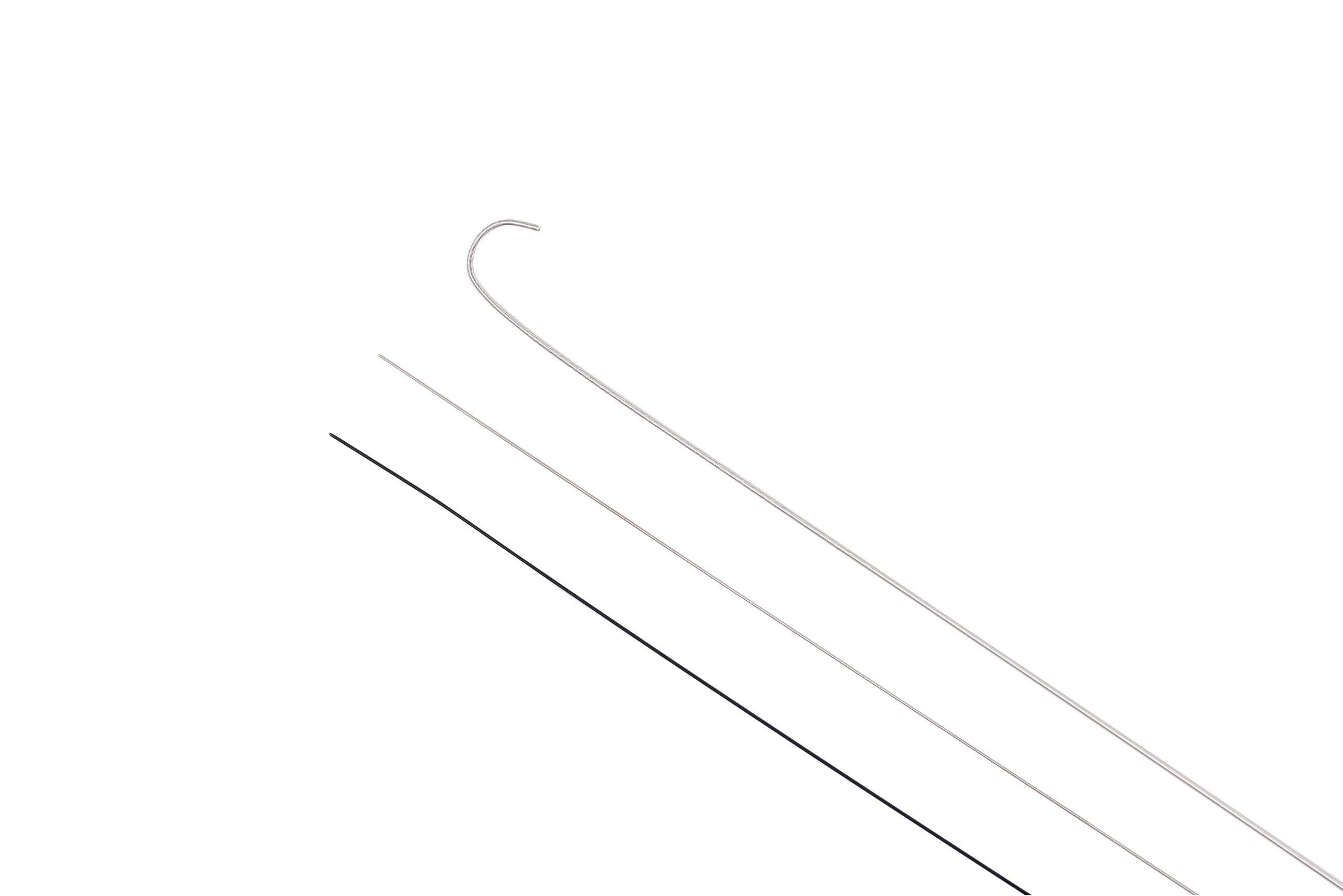

Pre-shaped Guidewire

The Pre-shaped Guidewire is a specialized medical device used in various diagnostic and interventional procedures to navigate through anatomical structures with precision. Crafted with precision and using high-quality materials, this guidewire offers exceptional flexibility, durability, and maneuverability, making it an indispensable tool for healthcare professionals performing a wide range of procedures.

-

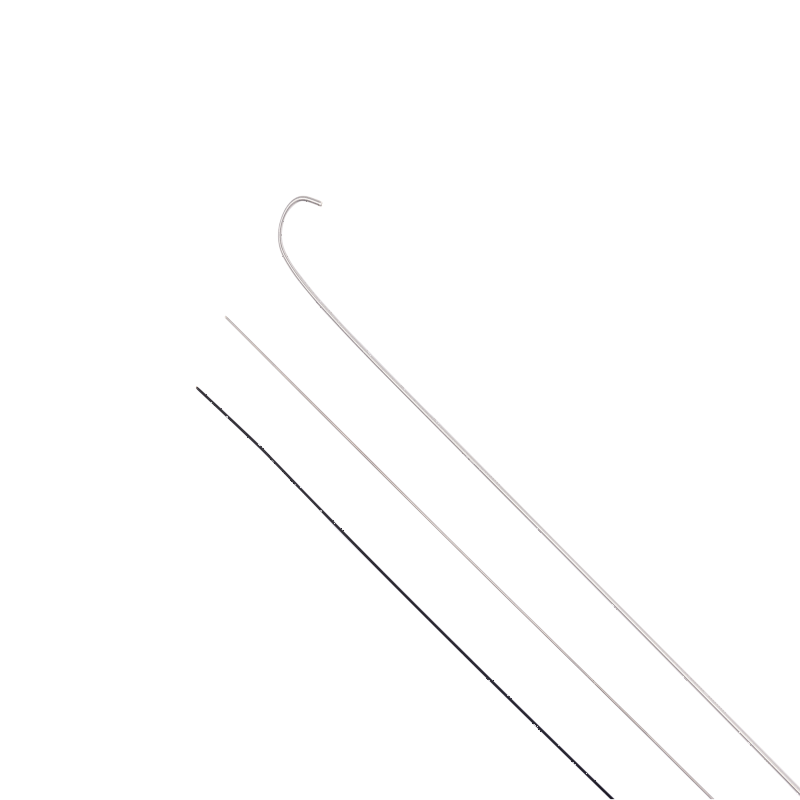

PTCA Guidewire

The Demax PTCA Guidewire is a specialized medical device designed to facilitate the precise navigation of catheters and balloons during percutaneous transluminal coronary angioplasty (PTCA) procedures. Crafted with precision and utilizing high-quality materials, this guidewire offers exceptional performance, flexibility, and durability, making it an indispensable tool for interventional cardiologists performing coronary interventions.

-

PTFE Guidewire

A PTFE (Polytetrafluoroethylene) Guidewire is a specialized medical device used in various diagnostic and interventional procedures to navigate through anatomical structures with precision. Crafted with precision and using high-quality materials, this guidewire offers exceptional flexibility, durability, and maneuverability, making it an indispensable tool for healthcare professionals performing a wide range of procedures.

-

PTFE Liner

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer that is used as a liner in catheters due to its unique properties. PTFE has a very low coefficient of friction and is a highly durable material with excellent tensile strength. Catheter liners made of PTFE can withstand the stresses of use in medical devices and resist breaking or tearing.

PTFE is used as a liner in catheters because it provides a smooth, low-friction surface that helps reduce the risk of infection and tissue damage. They are also biocompatible so that most people won’t experience an allergic reaction or any negative response.

-

PU Braided Tube

The Demax PU Braided Tube is constructed using polyurethane (PU), a high-performance polymer known for its excellent mechanical properties and chemical resistance. This tubing is reinforced with a braided layer, providing enhanced strength and resistance to kinking and collapse. It is manufactured to meet the stringent standards of the medical industry, ensuring biocompatibility and safety for patient use. The tubing is free from latex, phthalates, and other harmful substances, minimizing the risk of adverse reactions or complications.

-

Punching

Precision Medical Tubing Services Punching from Demax involves the precise creation of perforations, holes, or patterns in medical-grade tubing using advanced punching methods and equipment. The tubing material, typically made from medical-grade polymers such as polyethylene (PE), polyurethane (PU), or silicone, is carefully selected for its biocompatibility, flexibility, and durability. During the punching process, specialized punches and dies are used to create holes of specific sizes, shapes, and configurations in the tubing, allowing for precise control over the perforation characteristics. Each punched hole is inspected and verified to ensure that it meets the required tolerances and quality standards. Demax’s expertise in precision punching ensures that punched medical tubing maintains its structural integrity, biocompatibility, and performance, meeting the demanding requirements of medical device manufacturers and healthcare professionals.

-

Puncture Guidewire

Puncture Guidewire is composed of a stainless steel core wire and a stainless steel winding wire. The core wire provides stiffness and support for navigating through anatomical pathways, while the winding wire enhances flexibility and maneuverability. This composition ensures the guide wire’s durability and reliability during minimally invasive procedures, allowing healthcare professionals to navigate with precision and achieve successful outcomes for their patients.

-

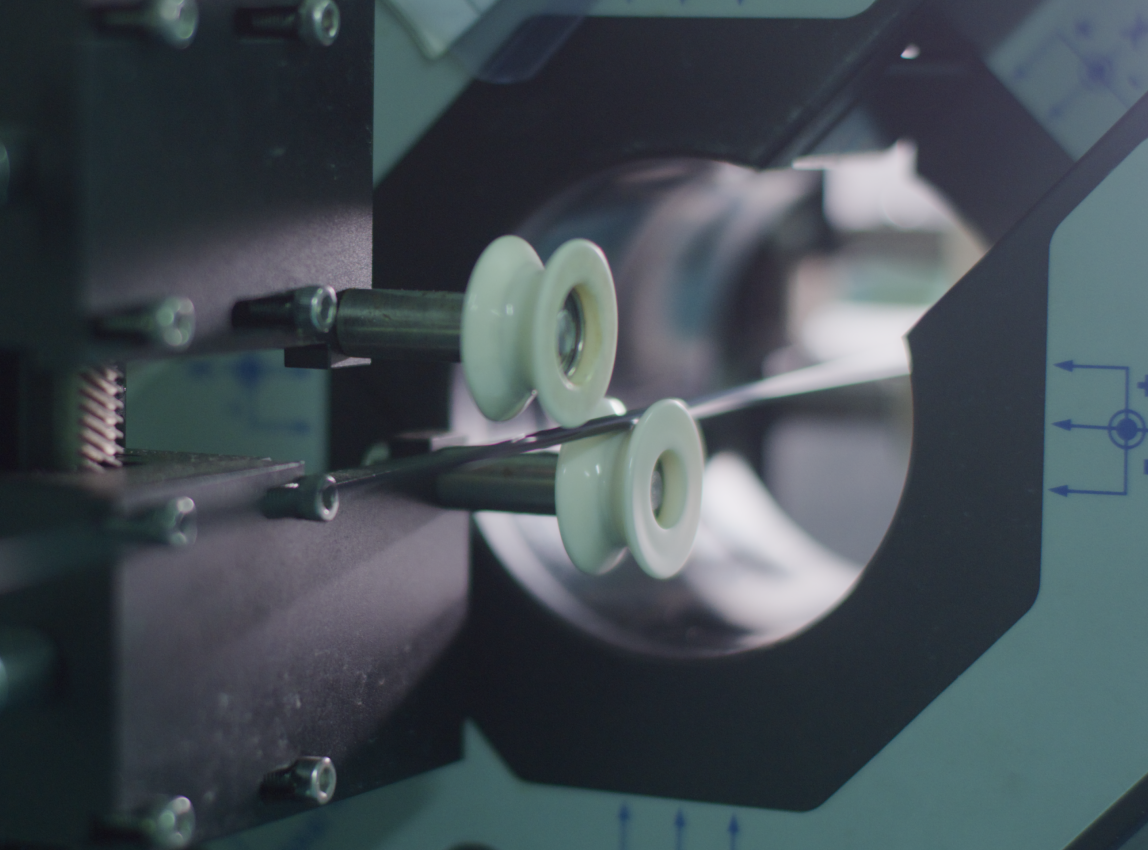

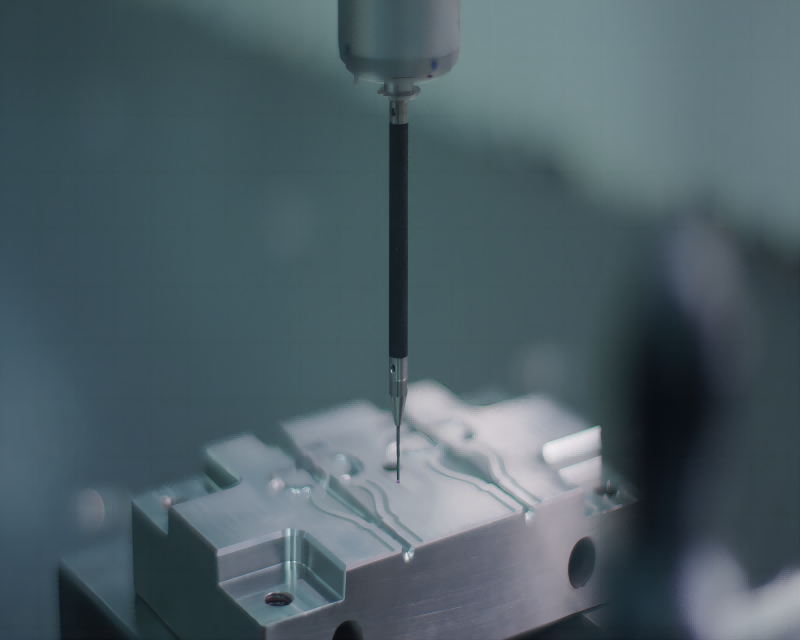

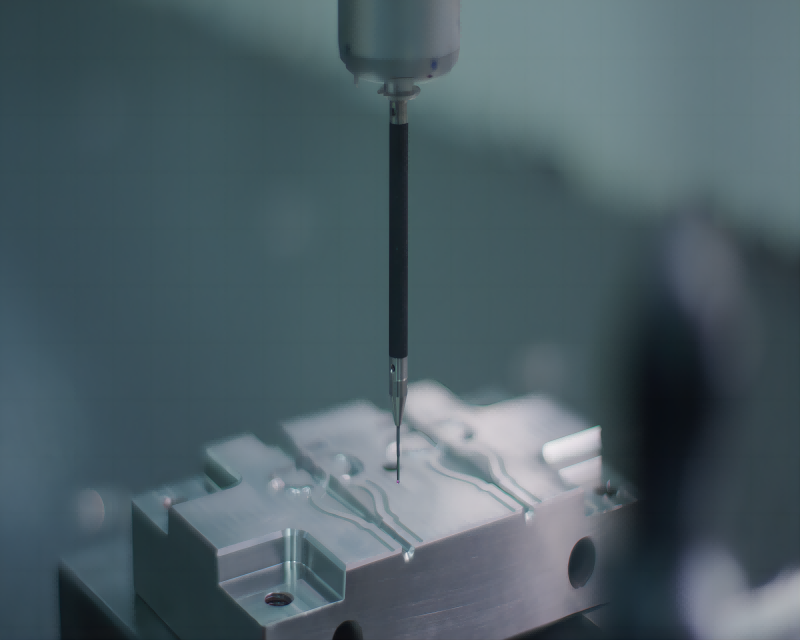

Spring Winding

The composition of springs produced with Demax Spring Winding varies depending on the application requirements. These springs can be wound from a variety of materials, including high-carbon steel, stainless steel, titanium, and specialty alloys, chosen for their mechanical properties and corrosion resistance. Additionally, depending on the application, springs may undergo surface treatments such as heat treatment, shot peening, or coating to enhance durability, fatigue resistance, and performance in challenging environments

-

Stainless-steel Guidewire

The Demax Stainless-steel Guidewire are constructed using high-quality stainless steel, ensuring excellent flexibility, durability, and biocompatibility. The guidewires are available in various configurations, including straight and J-tip designs, to accommodate different procedural requirements and patient anatomies.

-

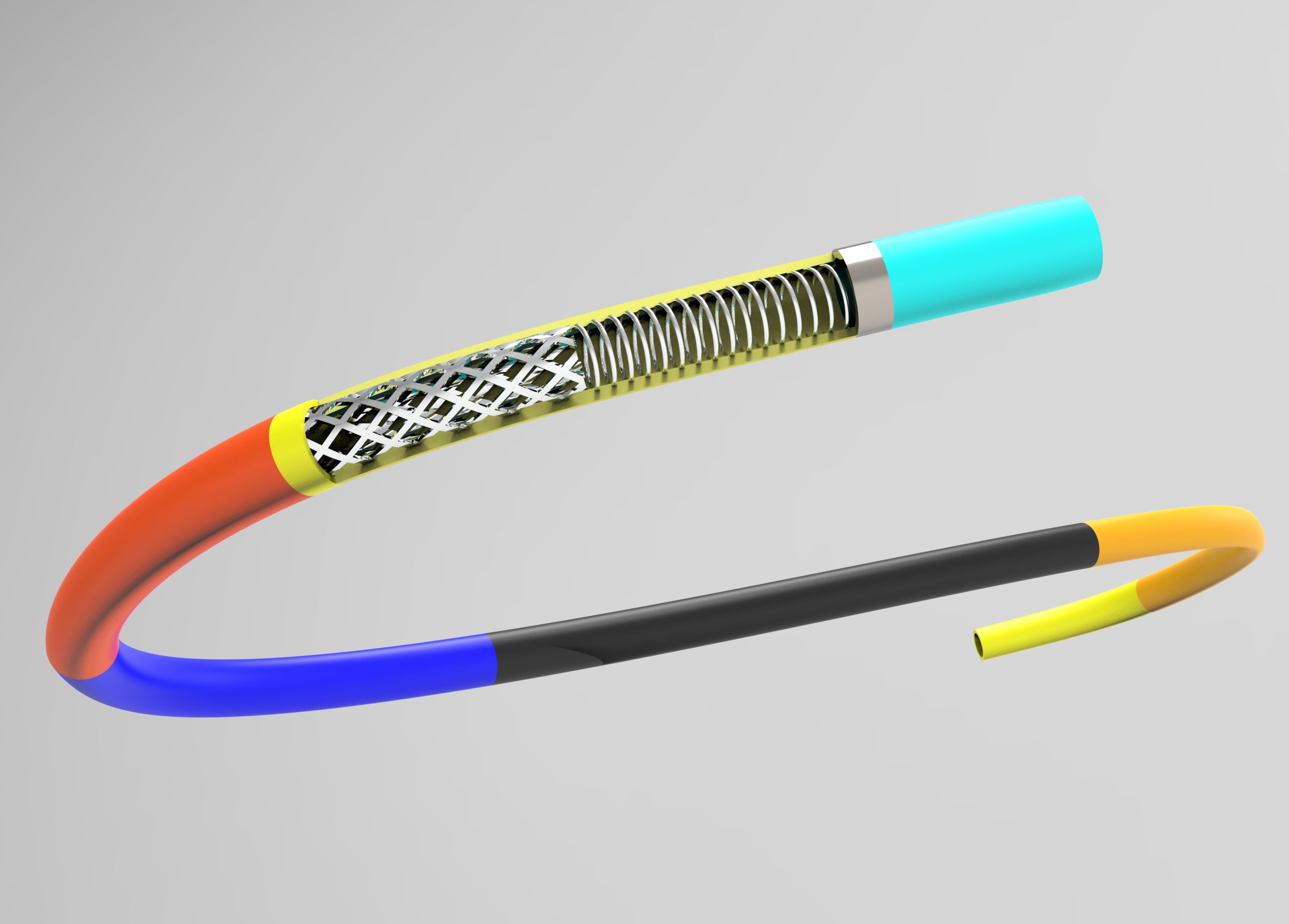

Stent delivery system Braided catheter

Establishing an access channel forinstruments to enter the body

Customizable in various sizes to meet different lesion requirements

-

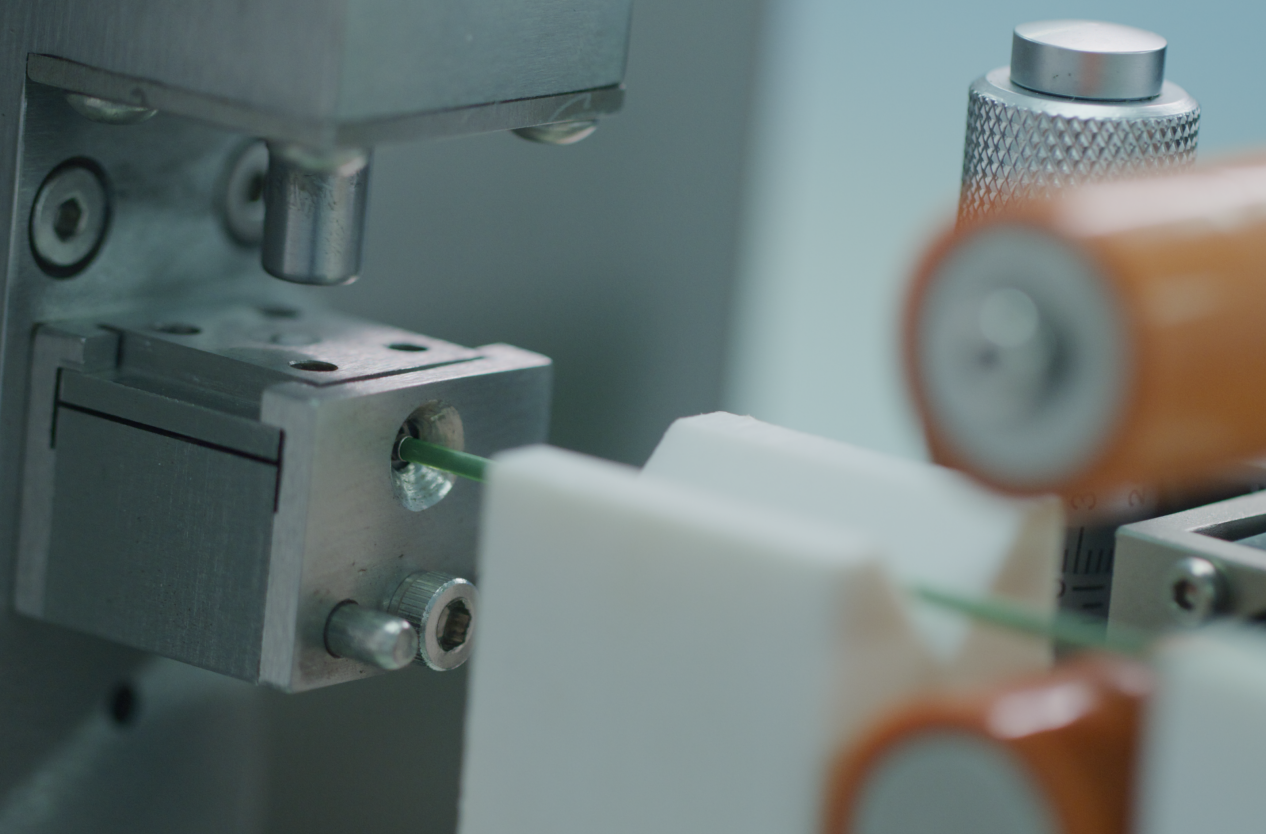

Testing

Demax’s Intelligent Manufacturing Production Equipment Testing service combines advanced testing methodologies, state-of-the-art equipment, and experienced professionals to ensure the reliability and performance of automated manufacturing systems. The composition of this service includes a variety of testing protocols tailored to specific requirements, advanced testing equipment such as specialized rigs and data acquisition systems, and a team of skilled testing engineers with expertise in industrial automation and quality assurance.

-

Tip Forming

Precision Medical Tubing Services Tip Forming involves shaping and forming the tips of medical-grade tubing materials to meet the specific requirements of medical device applications. The composition of the tubing used in this process varies depending on the desired properties and performance characteristics required for the medical device. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

-

Pre-shaped Guidewire

The Pre-shaped Guidewire is a specialized medical device used in various diagnostic and interventional procedures to navigate through anatomical structures with precision. Crafted with precision and using high-quality materials, this guidewire offers exceptional flexibility, durability, and maneuverability, making it an indispensable tool for healthcare professionals performing a wide range of procedures.

-

PTCA Guidewire

The Demax PTCA Guidewire is a specialized medical device designed to facilitate the precise navigation of catheters and balloons during percutaneous transluminal coronary angioplasty (PTCA) procedures. Crafted with precision and utilizing high-quality materials, this guidewire offers exceptional performance, flexibility, and durability, making it an indispensable tool for interventional cardiologists performing coronary interventions.

-

PTFE Guidewire

A PTFE (Polytetrafluoroethylene) Guidewire is a specialized medical device used in various diagnostic and interventional procedures to navigate through anatomical structures with precision. Crafted with precision and using high-quality materials, this guidewire offers exceptional flexibility, durability, and maneuverability, making it an indispensable tool for healthcare professionals performing a wide range of procedures.

-

PTFE Liner

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer that is used as a liner in catheters due to its unique properties. PTFE has a very low coefficient of friction and is a highly durable material with excellent tensile strength. Catheter liners made of PTFE can withstand the stresses of use in medical devices and resist breaking or tearing.

PTFE is used as a liner in catheters because it provides a smooth, low-friction surface that helps reduce the risk of infection and tissue damage. They are also biocompatible so that most people won’t experience an allergic reaction or any negative response.

-

PU Braided Tube

The Demax PU Braided Tube is constructed using polyurethane (PU), a high-performance polymer known for its excellent mechanical properties and chemical resistance. This tubing is reinforced with a braided layer, providing enhanced strength and resistance to kinking and collapse. It is manufactured to meet the stringent standards of the medical industry, ensuring biocompatibility and safety for patient use. The tubing is free from latex, phthalates, and other harmful substances, minimizing the risk of adverse reactions or complications.

-

Punching

Precision Medical Tubing Services Punching from Demax involves the precise creation of perforations, holes, or patterns in medical-grade tubing using advanced punching methods and equipment. The tubing material, typically made from medical-grade polymers such as polyethylene (PE), polyurethane (PU), or silicone, is carefully selected for its biocompatibility, flexibility, and durability. During the punching process, specialized punches and dies are used to create holes of specific sizes, shapes, and configurations in the tubing, allowing for precise control over the perforation characteristics. Each punched hole is inspected and verified to ensure that it meets the required tolerances and quality standards. Demax’s expertise in precision punching ensures that punched medical tubing maintains its structural integrity, biocompatibility, and performance, meeting the demanding requirements of medical device manufacturers and healthcare professionals.

-

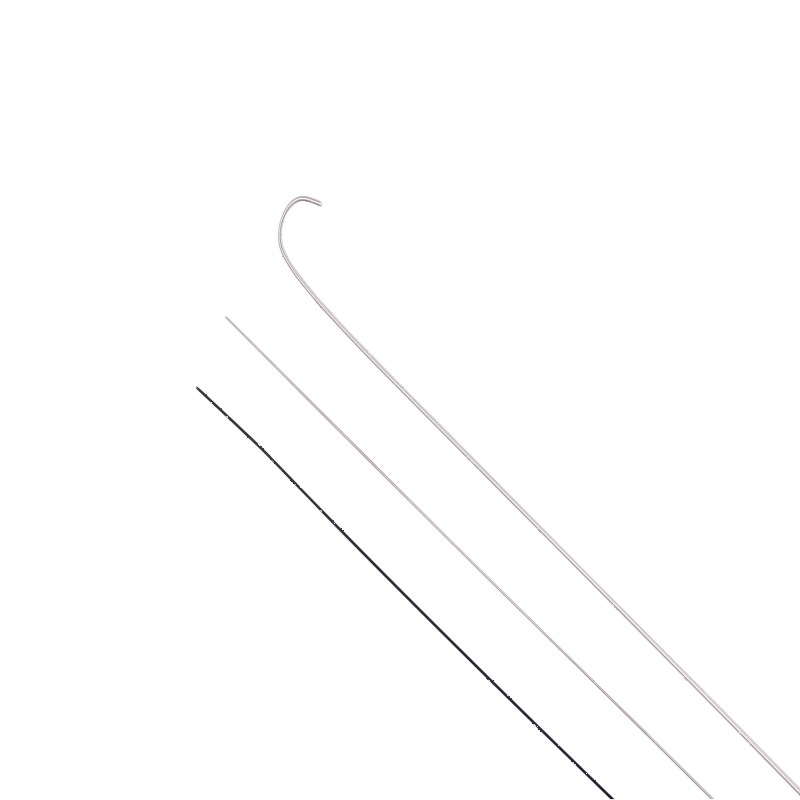

Puncture Guidewire

Puncture Guidewire is composed of a stainless steel core wire and a stainless steel winding wire. The core wire provides stiffness and support for navigating through anatomical pathways, while the winding wire enhances flexibility and maneuverability. This composition ensures the guide wire’s durability and reliability during minimally invasive procedures, allowing healthcare professionals to navigate with precision and achieve successful outcomes for their patients.

-

Spring Winding

The composition of springs produced with Demax Spring Winding varies depending on the application requirements. These springs can be wound from a variety of materials, including high-carbon steel, stainless steel, titanium, and specialty alloys, chosen for their mechanical properties and corrosion resistance. Additionally, depending on the application, springs may undergo surface treatments such as heat treatment, shot peening, or coating to enhance durability, fatigue resistance, and performance in challenging environments

-

Stainless-steel Guidewire

The Demax Stainless-steel Guidewire are constructed using high-quality stainless steel, ensuring excellent flexibility, durability, and biocompatibility. The guidewires are available in various configurations, including straight and J-tip designs, to accommodate different procedural requirements and patient anatomies.

-

Stent delivery system Braided catheter

Establishing an access channel forinstruments to enter the body

Customizable in various sizes to meet different lesion requirements

-

Testing

Demax’s Intelligent Manufacturing Production Equipment Testing service combines advanced testing methodologies, state-of-the-art equipment, and experienced professionals to ensure the reliability and performance of automated manufacturing systems. The composition of this service includes a variety of testing protocols tailored to specific requirements, advanced testing equipment such as specialized rigs and data acquisition systems, and a team of skilled testing engineers with expertise in industrial automation and quality assurance.

-

Tip Forming

Precision Medical Tubing Services Tip Forming involves shaping and forming the tips of medical-grade tubing materials to meet the specific requirements of medical device applications. The composition of the tubing used in this process varies depending on the desired properties and performance characteristics required for the medical device. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.